3 wear pads, Main boom, Wear pads -10 – JLG 601S ANSI Service Manual User Manual

Page 138: Main boom -10, Clamping wire ropes -10, Location and thickness of wear pads -10, 3 wear pads main boom

SECTION 4 - BOOM & PLATFORM

4-10

– JLG Lift –

3120746

3. Install adjusting nuts (or remove nylon collar lock-

nuts if re-adjusting) to both retract and extend wire

ropes.

4. Torque retract adjusting nuts (platform end) to 15 ft.

lbs. (20 Nm) alternating between the two wire ropes

and keeping approximately the same amount of

thread beyond the adjusting nut.

NOTE: Do not allow wire rope to rotate. This may damage

the wire rope.

5. Repeat the torque procedure in step #4 to the

extend wire ropes (turntable end).

6. Extend the boom 2 - 3 feet using the telescope func-

tion. Repeat step #4.

7. Retract the boom 1 - 2 feet using the telescope func-

tion. Do not bottom out telescope cylinder. Repeat

step #5.

8. Extend the boom approximately 2 - 3 feet again and

check torque on the retract wire ropes.

9. Retract the boom without bottoming out telescope

cylinder and check torque on the extend wire ropes.

NOTE: Step #8 and #9 may need to be repeated to equalize

the torque on all 4 wire ropes.

10. After all wire ropes have been properly torqued,

install nylon collar locknuts. Remove all clamping

devices and install all covers and guards. Check the

boom for proper function.

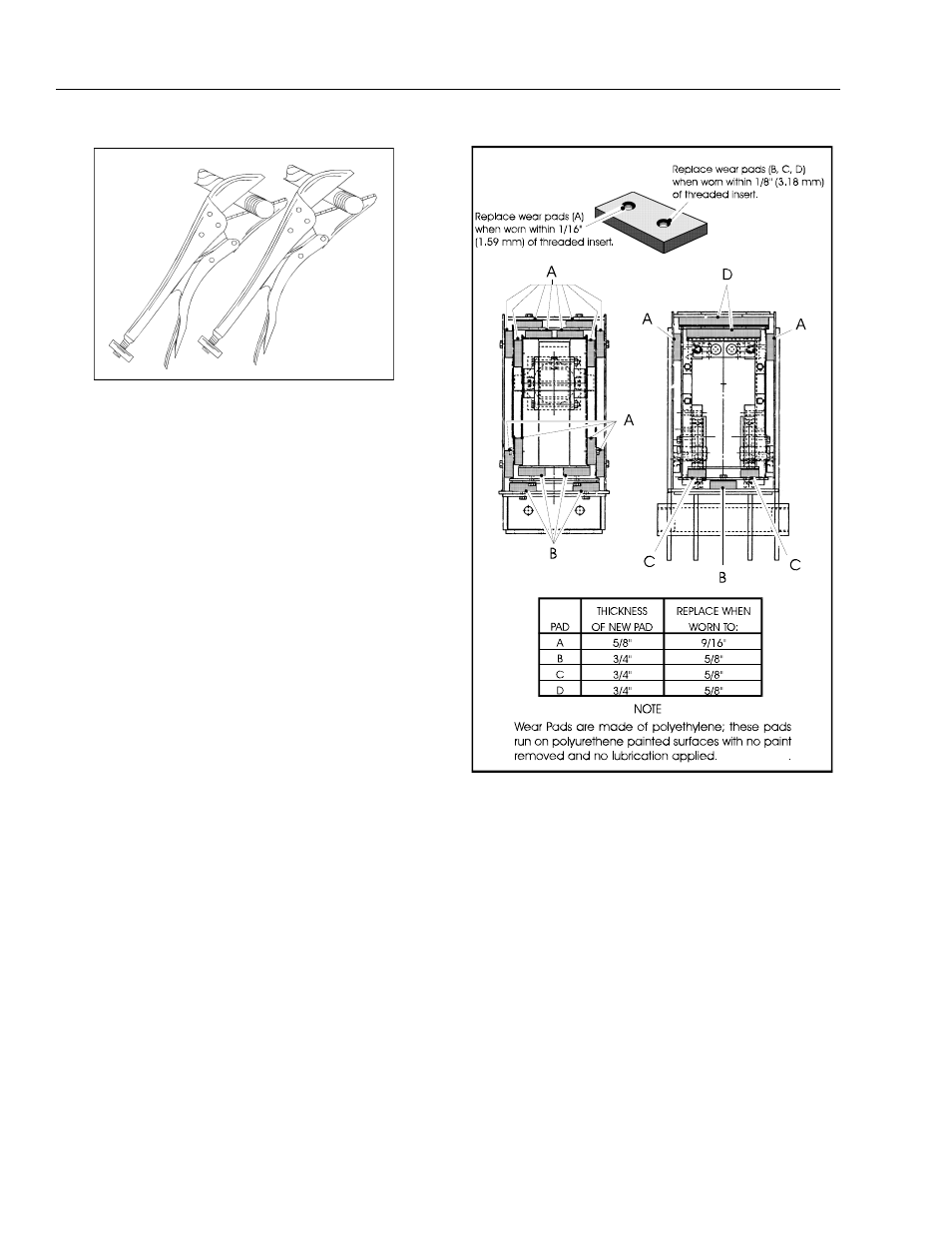

4.3 WEAR PADS

Main Boom

1. Shim up wear pads to within 1/32 inch (.79 mm) tol-

erance between wear pad and adjacent surface.

2. Replace wear pads when worn within 1/16 inch (1.59

mm) and 1/8 inch (3.18 mm) - B, C, D of threaded

insert. See Location and Thickness Of Wear Pads.

3. Adjusting wear pads, removing or adding shims,

bolt length must also be changed.

a. When adding shims, longer bolts must be used

to ensure proper thread engagement in insert.

b. When shims are removed, shorter bolts must be

used so bolt does not protrude from insert and

come into contact with boom surface.

Figure 4-12. Clamping Wire Ropes

Figure 4-13. Location and Thickness of Wear Pads