Typical fuel system -84 – JLG 601S ANSI Service Manual User Manual

Page 124

SECTION 3 - CHASSIS & TURNTABLE

3-84

– JLG Lift –

3120746

FUEL METERING SYSTEM PURPOSE

The basic function of the air/fuel metering system is to

control the air/fuel delivery to the engine. Fuel is delivered

to the engine by individual fuel injectors mounted in the

intake manifold near each intake valve.

The main control sensor is the heated oxygen sensor

(H02S) located in the exhaust system. The H02S tells the

Engine Module how much oxygen is in the exhaust gas.

The Engine Module changes the air/fuel ratio to the

engine by control-ling the amount of time that the fuel

injector is "ON." The best mixture to minimize exhaust

emissions is 14.7 parts of air to 1 part of gasoline by

weight, which provides the most efficient combustion.

Because of the constant measuring and adjusting of the

air/fuel ratio, the fuel injection system is called a "closed

loop" system.

The Engine Module monitors signals from several sensors

in order to determine the fuel needs of the engine. Fuel is

delivered under one of several conditions called "modes."

All modes are controlled by the Engine Module. Refer to

"Open Loop and Closed Loop Operation" for more infor-

mation.

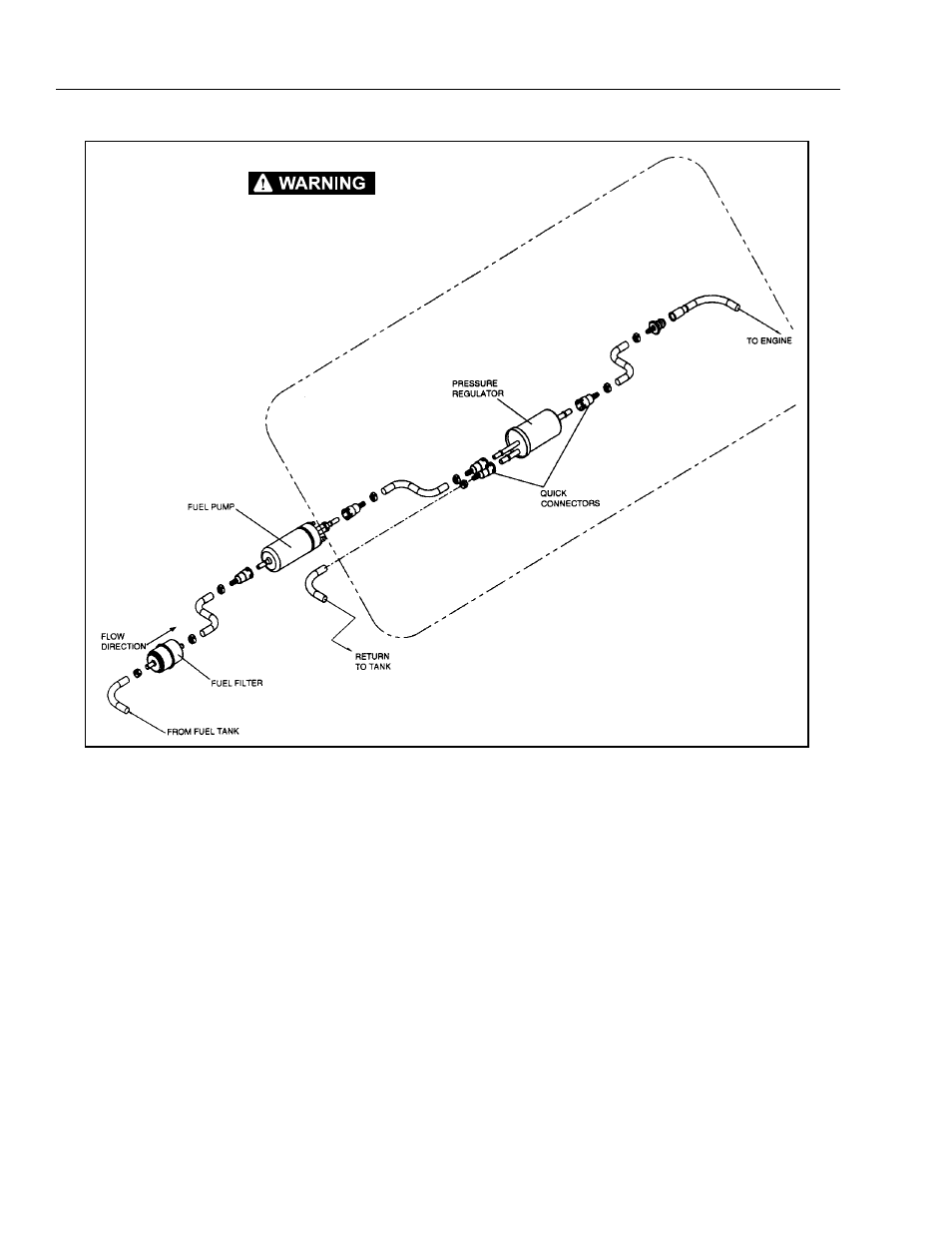

Figure 3-48. Typical Fuel System

HIGH PRESSURE CIRCUIT - OPERATING PRESSURE 65 PSI.