Minor repair and replacement, Minor repair and replacement -16, Variable displacement pump -16 – JLG 601S ANSI Service Manual User Manual

Page 164

SECTION 5 - HYDRAULICS

5-16

– JLG Lift –

3120746

Minor Repair and Replacement

Minor repairs may be performed, following the procedures

in this section.

Cleanliness is a primary means of assuring satisfactory

transmission life, on either new or repaired units. Cleaning

parts by using solvent wash and air drying is usually ade-

quate. As with any precision equipment, all parts must be

kept free of foreign materials and chemicals.

Protect all exposed sealing surfaces and open cavities

from damage and foreign material.

It is recommended that all gaskets and O-rings be

replaced. Lightly lubricate all O-rings with clean petroleum

jelly prior to assembly. All gasket sealing surfaces must be

cleaned prior to installing new gaskets.

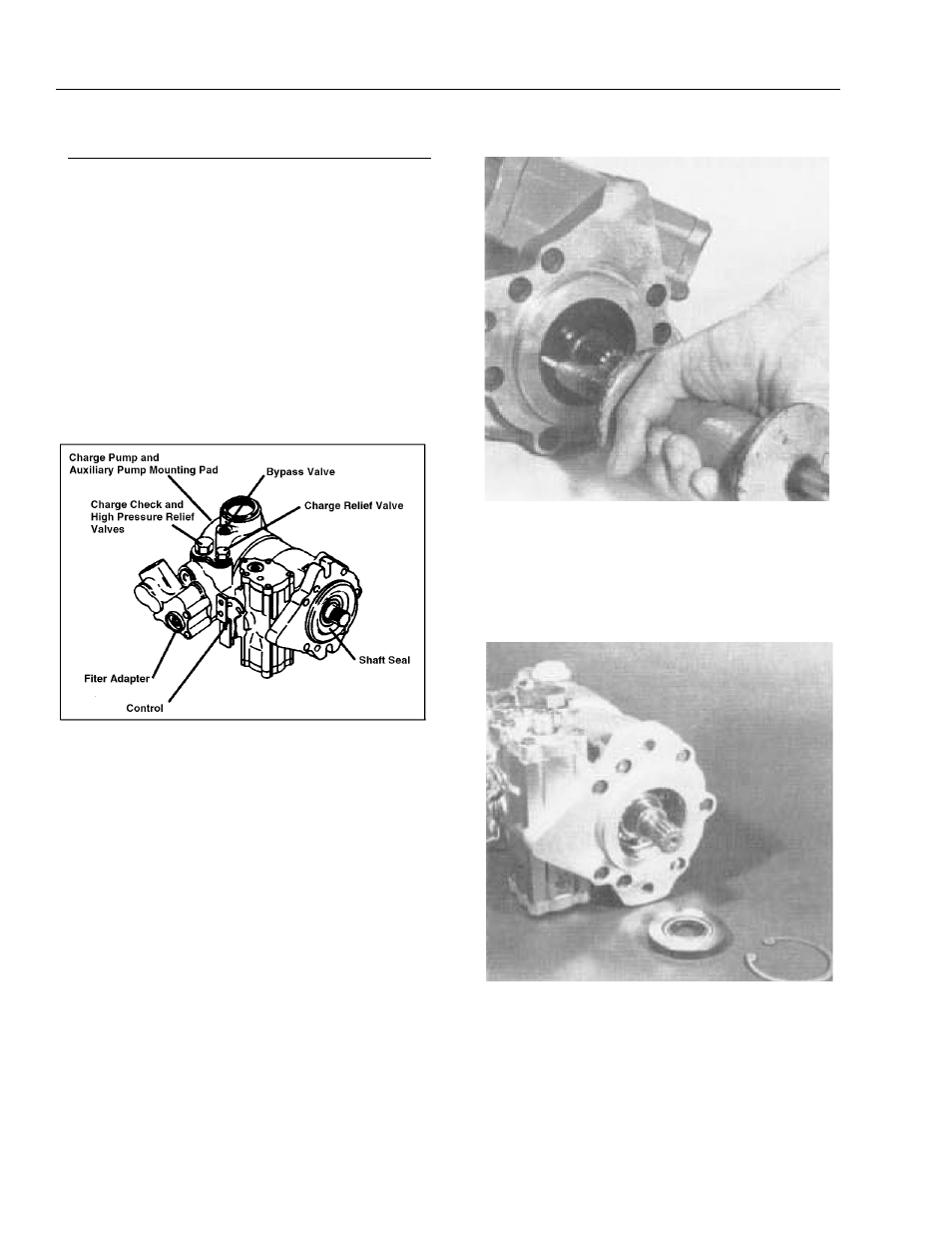

SHAFT SEAL

Lip type shafts are used on Series 40 - M46 pumps and

motors. These seals can be replaced without major disas-

sembly of the unit. However, replacement of the shaft seal

requires removal of the pump from the machine.

1. Remove the retaining ring from the housing.

2. Carefully remove the seal from the housing bore.

The face of the seal may be punctured with a sharp

instrument (such as a screw driver) to aid in prying

the seal out, or a slide hammer type puller may be

used to remove the seal. Care must be taken so as

not to damage the housing bore or shaft. Once

removed, the seal is not reusable.

3. Prior to installing the new seal, inspect the sealing

area on the shaft for rust, wear, or contamination.

Polish the sealing area on the shaft if necessary.

4. Wrap the spline or key end of the shaft with thin

plastic to prevent damage to the seal lip during

installation. Lubricate the inside diameter of the new

seal with petroleum jelly.

Figure 5-18. Variable Displacement Pump