System noise or vibration -34, Neutral difficult or impossible to find -34, Sluggish system response -34 – JLG 24RS Service Manual User Manual

Page 158

SECTION 5 - HYDRAULICS

5-34

– JLG Lift –

3121287

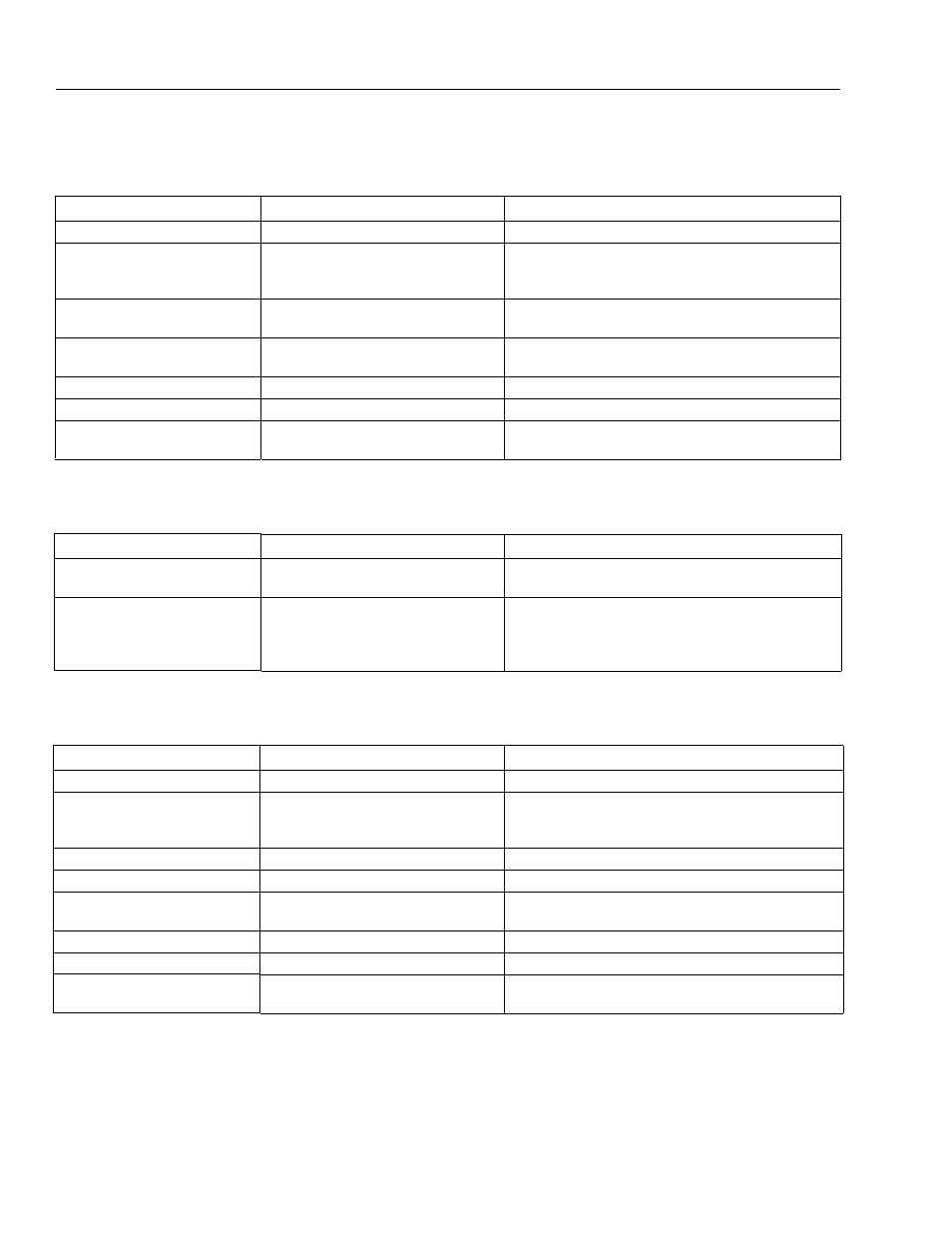

Table 5-5. System Noise or Vibration

Item

Description

Action

Reservoir oil level

Low oil level leads to cavitation.

Fill reservoir.

Aeration of the oil/pump inlet vacuum

Air in system decreases efficiency of units and controls.

Air in system is indicated by excessive noise in pump,

foaming in oil, and hot oil.

Find location where air is entering into the system and repair. Check that inlet

line is not restricted and is proper size.

Cold oil

If oil is cold, it may be too viscous for proper function and

pump cavitates

Allow the oil to warm up to its normal operating temperature with engine at

idle speed.

Pump inlet vacuum

High inlet vacuum causes noise/cavitation.

Check that inlet line is not restricted and is proper size. Check filter and bypass

switch.

Shaft couplings

A loose shaft coupling causes excessive noise.

Replace loose shaft coupling.

Shaft alignment

Misaligned pump and prime mover shafts create noise.

Align shafts.

Charge/system relief valves

Unusual noise may indicate sticking valves. Possible con-

tamination.

Clean/replace valves and test pump.

Table 5-6. Neutral Difficult or Impossible to Find

Item

Description

Action

Input to pump control

Input to control module is operating improperly.

Disconnect input and check to see if pump comes back to neutral. If Yes, input

fault, replace/repair external controller. If No, go to next step.

Pump control neutral

Neutral set improperly.

Shunt servo gauge ports M4 and M5 together with external hose and see if

pump comes back to neutral. If Yes: control neutral improperly set (see page

35). If no: balance swashplate (see Mechanical neutral adjustment, page 37). If

you still cannot set neutral, replace control.

Table 5-7. Sluggish System Response

Item

Description

Action

Oil level in reservoir

Low oil level causes sluggish response.

Fill reservoir.

High pressure relief valves/

pressure limiter settings

Incorrect pressure settings affects system reaction time. Adjust or replace high pressure relief valves.

Low prime mover speed

Low engine speed reduces system performance

Adjust engine speed.

Charge pressure

Incorrect pressure affects system performance

Measure and adjust charge pressure relief or replace charge pump.

Air in system

Air in system produces sluggish system response

Fill tank to proper level. Cycle system slowly for several minutes to remove air

from system.

Contaminated control orifices

Control orifices are plugged.

Clean control orifices.

Contaminated control screens

Control screens are plugged.

Clean or replace control screens.

Pump inlet vacuum

Inlet vacuum is too high resulting in reduced system

pressure.

Measure charge inlet vacuum. Inspect line for proper sizing. Replace filter. Con-

firm proper bypass operation.