Error codes, Technical data – IKA RV 10 control FLEX User Manual

Page 56

57

032010

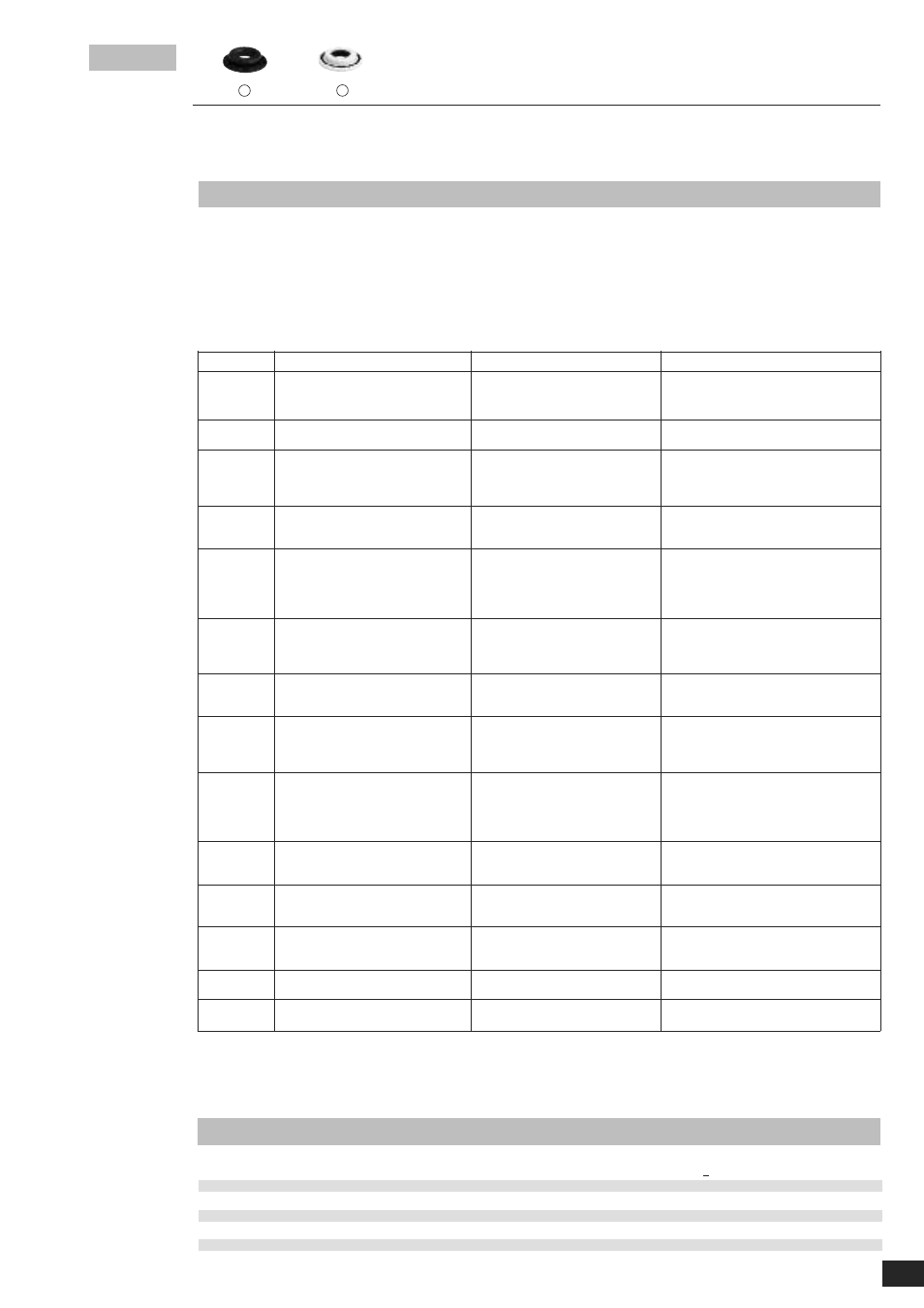

Error codes

Any malfunctions during operation will be identified by an error message on the display.

Once a serious error message has been displayed, the lift moves to the top end position and the device can no longer be operated. The lift can

be operated again.

Proceed as follows in such cases:

Switch off device using the main switch

Carry out corrective measures

Restart device

Error

Effect

Cause

Correction

Communication Distillation canceled in "Auto-distillation" mode IR interface obstructed

- Press ESC to confirm

error bath

Heating bath switched off

- Switch on heating bath

- Check and clean IR interface

No rotation

Distillation stopped,

Rotary drive does not start or

- Switch device off and on at mains switch

no rotary drive

exhibits very large speed variation

No temperature

Distillation canceled in "Auto-distillation" mode No differential temperature increase of

- Press ESC to confirm

difference

cooling water

- Check flow of cooling water

- Check that the cooling water hoses are fitted

correctly

Temperature

Distillation stopped

Differential temperature outside

- Press ESC to confirm

out of range

measurement range (> 7 K)

- Check that the cooling water hoses are fitted

correctly

No vacuum

Distillation stopped

Vacuum target value not reached

- Press ESC to confirm

Vacuum cannot be controlled

- Check that the glassware and hose connections

are properly sealed

- Switch on the pump

- Check the solenoid valve connections

No venting

Vacuum cannot be vented

No venting of condenser

- Switch off the device

- Vacuum sensor faulty

- Manually vent the glassware using the stop

valve

Water valve

Water runs continuously into cooling circuit

Water valve not closed

- Press ESC to confirm

not closed

- Check the connection

Flow rate

Distillation canceled in "Auto-distillation" mode Flow rate of cooling water out of range

- Press ESC to confirm

out of range

- Readjust flow rate

- Switch off flow rate control

(for dry ice coolers)

Condenser

Distillation stopped

Condenser overload

- Press ESC to confirm

overload

Distillate may be able to enter the vacuum

- Change process parameters, e.g.

pump

- Increase pressure

- Reduce bath temperature

- Increase condenser flow rate within specified range

Distillation

Distillation stopped

The system detected that there was no

- Press ESC to confirm

dry

more medium in the evaporating flask

- Alternatively, activate the “Drying” option

during the distillation.

in the “Settings” menu

Lift not in

Distillation stopped

Obstruction in path of lift

- Press ESC to confirm

end position

Lift motor switches off

- Check the path of the lift.

- Remove any obstructions.

Calibration error

Calibration reset to factory setting

Out of calibration range (max. +/-0.5 K)

- Press ESC to confirm

- Check that the sensor is connected correctly

- Carry out a new calibration procedure

Memory error

Calibration parameter for vacuum reset to

Error by checking contents of memory

Vacuum must be recalibrated

factory setting

Vacuum leak

Distillation stopped

Leak in vacuum system

Press ESC to confirm

Locate leak

If the actions described fail to resolve the fault or another error code is displayed then take one of the following steps:

- Contact the service department,

- Send the device for repair, including a short description of the fault.

RV 06.13

Seal FKM, PTFE-coated (1)

RV 06.15

Seal PTFE (2)

PC 1.1

Cable

labworldsoft

®

2

1

Technical Data

Operating voltage range

Vac

100 - 230 + 10%

Rated voltage

Vac

100 - 230

Frequence

Hz

50 / 60

Power input without heating bath

W

100

Power input operation “stand by”

W

3,3

Speed

rpm

20-280

Speed display

digital