General maintenance, General main tenan ce – SkyTrak 10054 Operation Manual User Manual

Page 174

172

Model 10054

Rev 3/02

General Maintenance

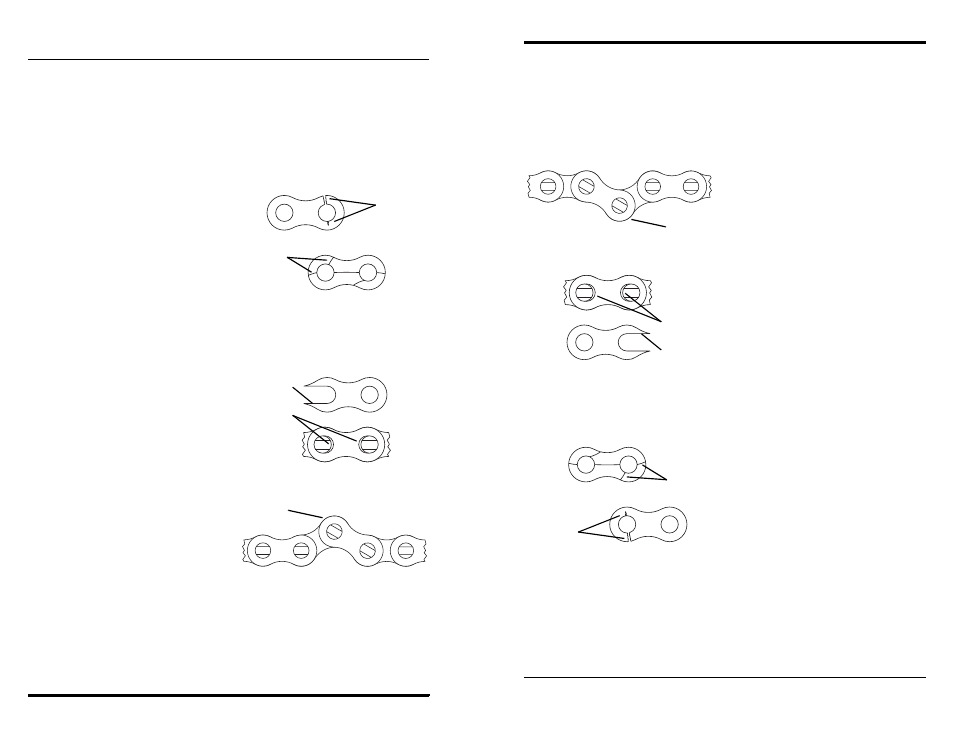

Cracked Plates

Inspect the chains very carefully, front and back as well as side to side,

for any evidence of cracked plates. If any one crack is discovered, the

chain should be replaced in its entirety.

it is important, however to determine the cause of the crack before

installing a new chain so the condition does not repeat itself.

The types of cracks are:

• Fatigue Cracking - Fatigue

cracks (1) are a result of

repeated cyclic loading beyond

the chain’s endurance limit.

• Stress Corrosion Cracking -

The outside link plates are

particularly susceptible to stress

corrosion cracking (2).

• Corrosion Fatigue Cracking - Corrosion fatigue cracks are very

similar to fatigue cracks in appearance. Corrosion fatigue is the

combined action of an aggressive environment and cyclic stress.

Other Modes of Failure

• Ultimate Strength Failure -

These types of failures are

caused by overloads far in

excess of the design load.

Either fractured plates (3) or

enlarged holes (4) can occur. If

either of these failures occurs,

the chain should be replaced

immediately.

• Tight Joints - All joints in

the chain should flex freely.

Tight joints (5) resist

flexing.

If the problem is caused by

dirt or foreign substance

packed in the joints, clean

and lubricate thoroughly before re-installing the chain.

If the problem is caused by corrosion and rust or bent pins,

replace the chain.

MM2070

1

MM2080

2

MM2100

3

MM2090

4

MM2110

5

172

Model

10054

Rev

3/02

General

Main

tenan

ce

Crac

kedP

lates

Insp

ect

the

chain

sv

ery

car

efully

,fr

ont

andbac

ka

sw

ell

as

sid

et

os

id

e,

fo

ra

ny

ev

id

en

ce

of

cra

ck

ed

plat

es

.I

fa

ny

one

cra

ck

isdi

scove

red,

th

e

cha

in

sho

uld

ber

eplac

edi

ni

ts

entir

ety.

it

is

imp

ortan

t,how

eve

rt

ode

termi

nethe

cau

seof

the

crac

kbe

fo

re

ins

tal

ling

ane

wc

hain

so

the

con

dition

does

notr

epea

ti

tsel

f.

Th

et

ypes

ofcra

cks

are:

•

Fat

ig

ue

Crac

kin

g-

Fa

tig

ue

crac

ks

(1

)a

re

ar

es

ult

of

re

peate

dc

yclic

loadi

ngbe

yond

the

chai

n’s

endu

rance

lim

it.

•

Stres

sCo

rro

sion

Crac

king

-

Th

eo

utsi

deli

nkpl

atesar

e

par

tic

ular

ly

susc

eptib

le

tos

tres

s

corro

sio

ncr

ack

ing

(2

).

•

Corrosion

Fa

tigueCr

ac

king

-C

orrosi

onf

atigue

crac

ks

are

ver

y

sim

ila

rt

of

atig

uec

rac

ks

inappe

arance

.C

orro

sion

fa

tigue

is

the

comb

in

ed

acti

on

of

anag

gre

ssi

ve

envi

ronm

en

ta

ndcy

clic

str

es

s.

OtherM

odeso

fF

ailur

e

•

Ult

imat

eS

trengt

hF

ailure

-

The

se

ty

pesof

fa

ilur

esar

e

cau

sed

by

ov

erload

sf

ar

in

ex

cess

ofthe

desig

nl

oad.

Eith

erfr

actur

ed

plate

s(

3)o

r

enla

rg

edhol

es(

4)

ca

noc

cur

.If

eith

erof

thes

ef

ailur

es

occ

urs

,

the

chai

ns

hould

ber

epl

aced

imm

ediatel

y .

•

TightJoints

-A

llj

oin

tsin

the

chai

ns

hould

fle

xfr

eely

.

Tight

joints

(5)

res

ist

fle

xing.

Ifthe

prob

lemis

cau

sed

by

dirt

orf

orei

gn

su

bs

ta

nce

pa

ck

ed

in

th

ej

oin

ts

,c

le

an

and

lubr

ic

atethor

oughl

ybef

ore

re-

ins

tal

ling

the

chai

n.

Ifthe

prob

lemis

cau

sed

by

cor

ro

sio

nan

dr

ust

or

bent

pin

s,

repl

ac

et

he

chai

n.

MM2070

1

MM

2080

2

MM

2100

3

MM2090

4

MM2110

5