Ge nera lm ain ten anc e, General maintenance – SkyTrak 10054 Operation Manual User Manual

Page 173

Ge

nera

lM

ain

ten

anc

e

171

Model

10054

Rev

3/02

Tu

rn

ingor

Protr

udingPins

(Figure

122)

High

lylo

adedc

hain,

oper

ating

within

adequa

telubr

ic

atio

nc

ang

enerate

abno

rm

alfr

icti

onal

for

ces

betweenpi

nan

dl

ink

plate

s.

When

chai

ni

s

allo

we

dt

oope

ra

tein

this

cond

ition,

ap

in

or

seri

es

ofpin

s,

can

begi

nt

o

twis

to

ut

ofa

chai

n,r

es

ult

in

gi

nf

ailu

re

.

Ex

am

in

et

hep

in

head

riv

ets

to

de

ter

mine

if

the

“V

EE

”flat

sa

res

till

in

cor

rec

tal

ignme

nt.Ch

ain

with

rota

ted/di

splac

edhea

dsor

abnor

mal

pin

prot

ru

sion

sho

uld

be

repl

ac

ed

im

me

diat

ely

.

DONO

Tatt

empt

tor

epai

rt

hecha

inb

yweld

ingor

driv

ingthe

pin(

s)

bac

kint

oth

ec

hain.

On

cethe

pres

sfi

ti

nteg

rity

between

outside

plat

es

and

pins

has

been

alter

ed,

it

ca

nnot

ber

estor

ed.

An

yw

ear

patte

rn

onthe

pin

heads

orth

es

ides

ofth

el

ink

plat

es

indi

ca

tesmi

salignm

entin

th

es

yste

m.T

his

condi

tion

damag

est

he

cha

in

as

wellas

in

cre

as

es

fri

cti

onal

load

ing

an

ds

hould

bec

orr

ec

ted

.

Figu

re

12

2

Dist

ort

ed

or

Bat

te

redLink

Plat

es

Dis

tor

ted

orb

attered

link

plate

s(

Figur

e1

23)on

al

eaf

ch

ain

can

cau

se

tigh

tj

oint

sa

ndp

re

ven

tf

lex

in

g.

Figu

re

12

3

MM2060

VEEF

latsCorrect

Alignmen

t

Rotate

dH

ea

ds

Abnormal

Pin

Protrusion

MA9340

Distorted

orBatte

red

Lin

kP

la

tes

General Maintenance

171

Model 10054

Rev 3/02

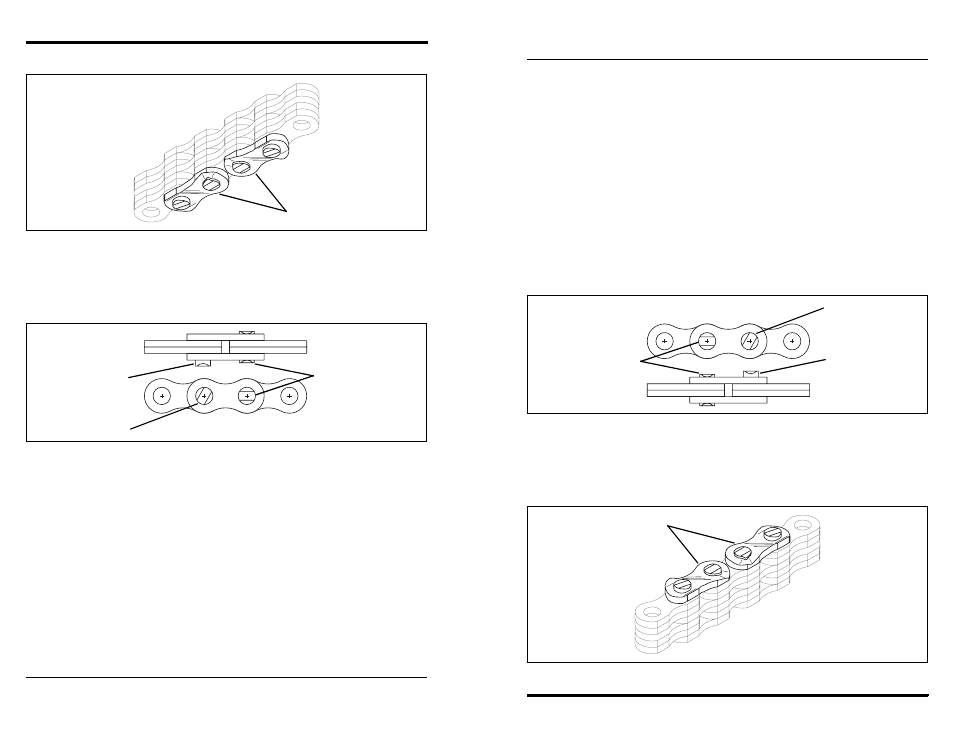

Turning or Protruding Pins (Figure 122)

Highly loaded chain, operating with inadequate lubrication can generate

abnormal frictional forces between pin and link plates. When chain is

allowed to operate in this condition, a pin or series of pins, can begin to

twist out of a chain, resulting in failure.

Examine the pin head rivets to determine if the “VEE” flats are still in

correct alignment. Chain with rotated/displaced heads or abnormal pin

protrusion should be replaced immediately.

DO NOT attempt to repair the chain by welding or driving the pin(s)

back into the chain. Once the press fit integrity between outside plates

and pins has been altered, it cannot be restored.

Any wear pattern on the pin heads or the sides of the link plates

indicates misalignment in the system. This condition damages the chain

as well as increases frictional loading and should be corrected.

Figure 122

Distorted or Battered Link Plates

Distorted or battered link plates (Figure 123) on a leaf chain can cause

tight joints and prevent flexing.

Figure 123

MM2060

VEE Flats Correct

Alignment

Rotated Heads

Abnormal Pin

Protrusion

MA9340

Distorted or Battered

Link Plates