Gradall LOED 534A Service Manual User Manual

Page 72

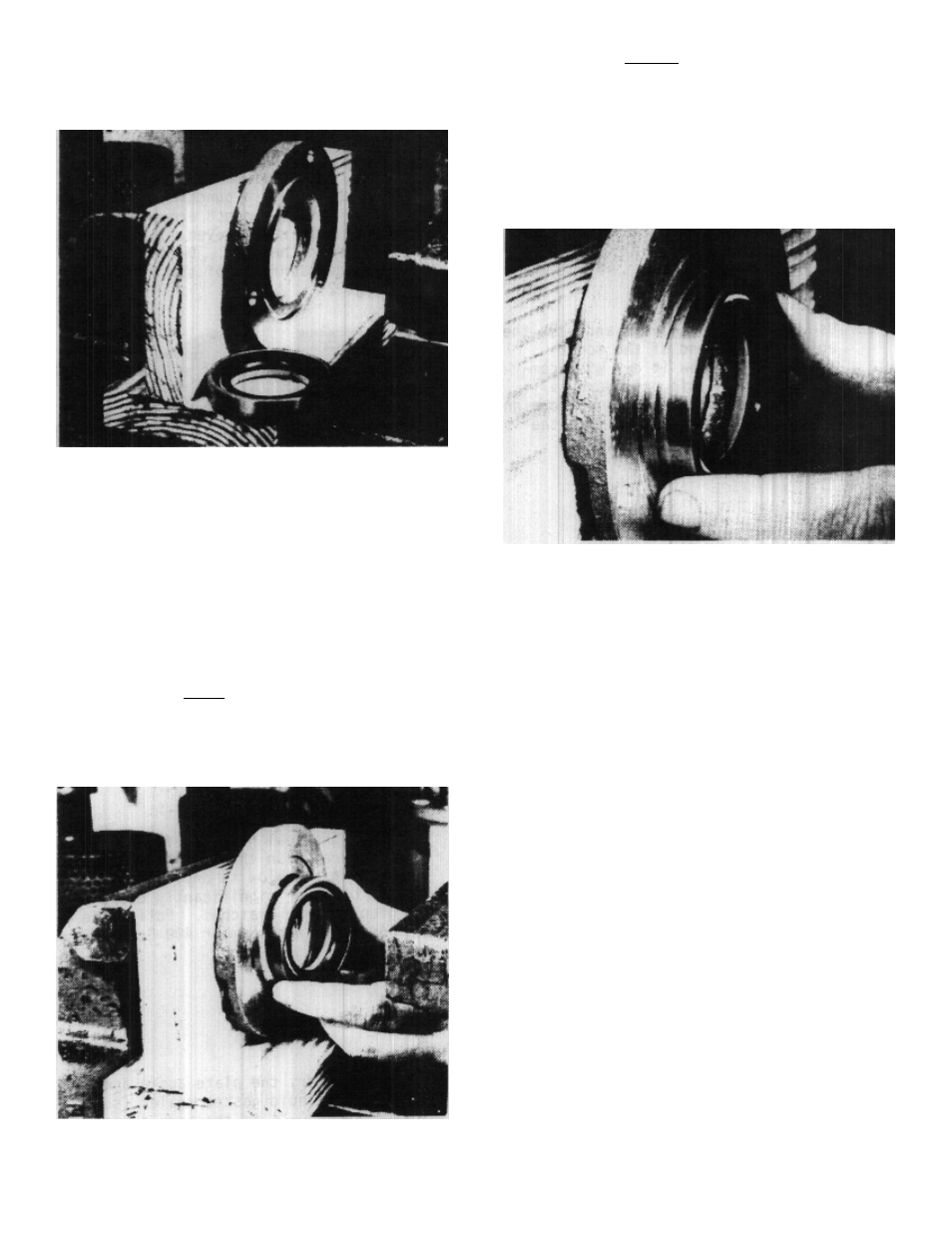

P l a c e t h e s e a l p l a t e b e t w e e n t h e

o p e n j a w s o f a m a c h i n i s t ’s v i s e w i t h

t h e c a s t s u r f a c e a g a i n s t t h e s t a t i o n -

any jaw. (Fig. 115)

Position the metal face of the new

seal over the seal bore. Make sure

it is centered and trued for entry

into the bore. (Fig. 116)

Place a smooth, clean block of wood

against the rubber face of the seal.

Carefully tighten the vise and press

the seal into the bore. The seal

will seat with about half of its

thickness dimension still protruding

from the bore. This protrusion

serves as a pilot while reinstalling

the plate on the flange. (Fig. 117)

Install a new seal plate o-ring in

its groove. Use clean heavy grease

to hold the o-ring in place.

If the motor drive shaft is keyed,

cover the keyway with thin tape to

protect the seal lip as it travels

down the shaft. If the shaft is

splined, coat the splines with clean,

heavy grease. (Fig. 118)

72

7.

8.

9.

10.

11.

FIGURE 115

FIGURE 116

FIGURE 117