Gradall LOED 534A Service Manual User Manual

Page 52

Correct the cause of interference

and reassemble the pump.

When the shaft turns properly,

lubricate the stud threads with

SAE 10 oil and torque all of the

nuts 80 to 90 lbs/ft. each.

(Figure 67)

41.

42.

43.

44.

45.

52

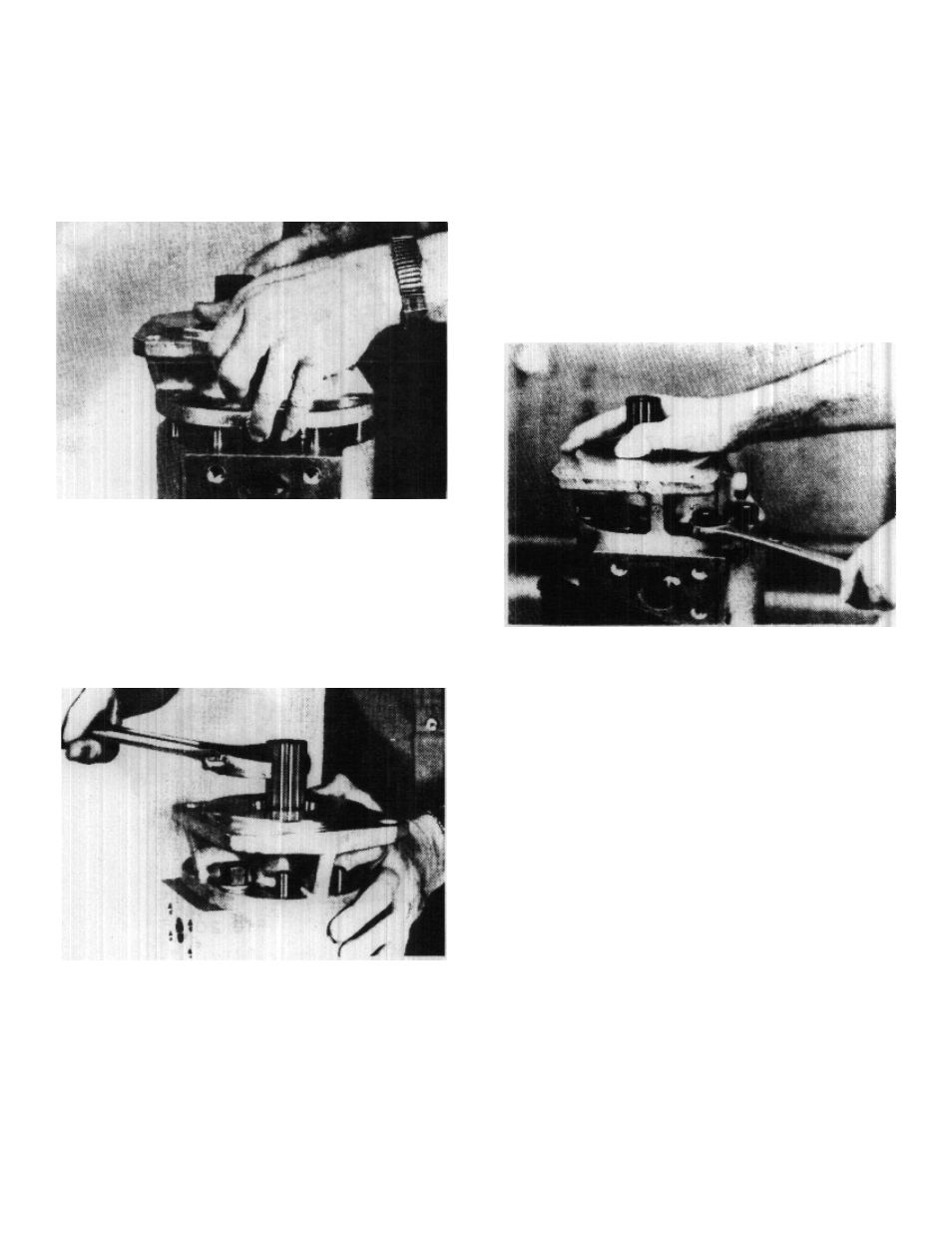

FIGURE 65

FIGURE 66

FIGURE 67

Install o-ring (24) in the flange

plate. Use heavy grease to hold

the o-ring in the groove while the

plate slides down over the shafts.

Refer to Step 32 and use the same

precautions in the final assembly

of the flange plate. (Figure 65)

Install washers (26) and nuts (23).

Tighten two opposite nuts. Use a

10" wrench to check the shaft for

binding. It should turn with 5 to

7 pounds-feet of torque applied.

(Figure 66)

If the shaft will not turn properly,

disassemble the pump and examine it

for burrs or foreign material caus-

ing build-up or interference with

the parts. Also check for the

isolation plate with the radius

edge not being in the bottom of the

gear bore.