4 improving data for feeding the curve fitter, 1 understanding the data and data format, An374 – Cirrus Logic AN374 User Manual

Page 25: 4m r, Eq. 22, Does not change, Code, Series, 1 t1 t0

AN374

AN374REV2

25

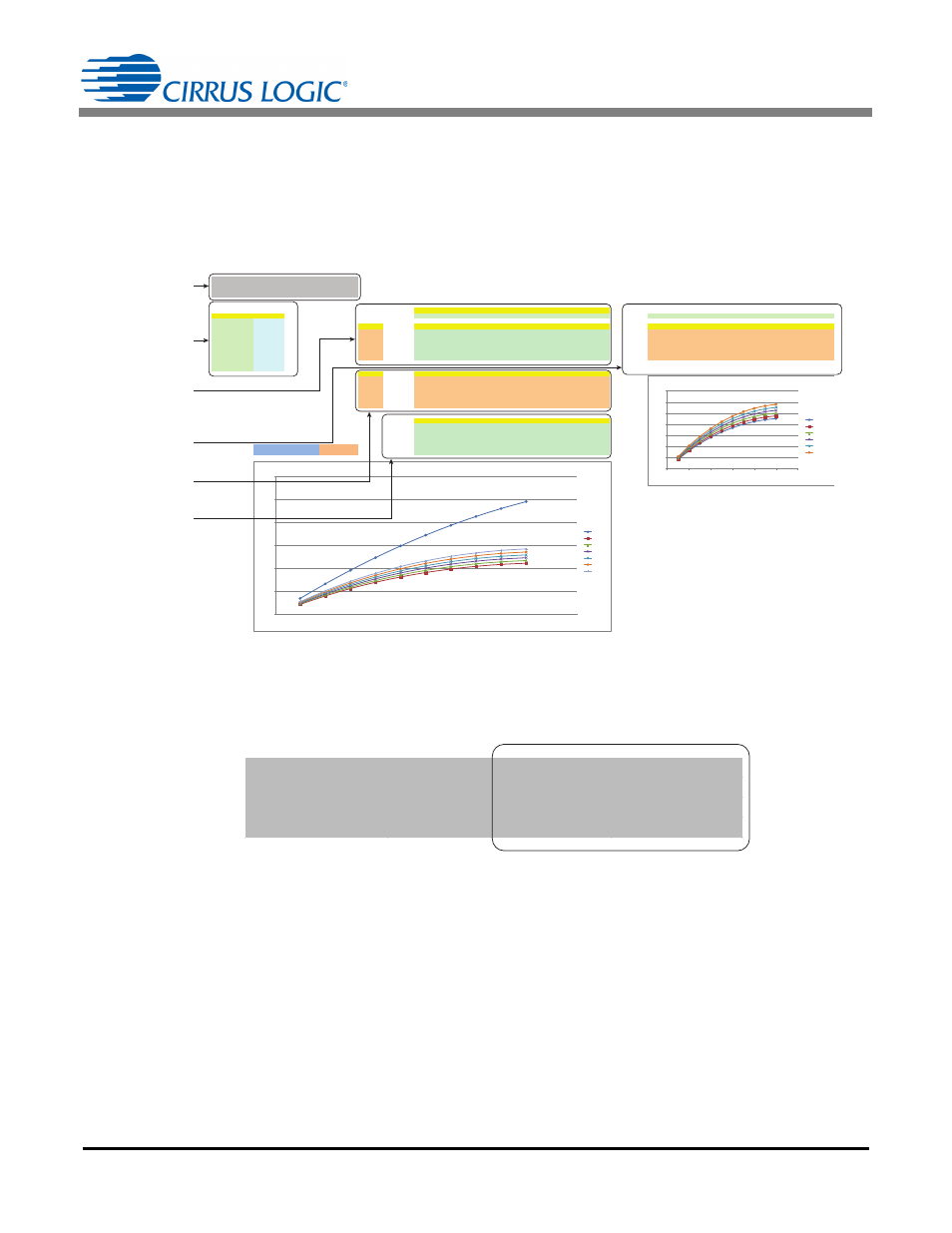

6.4 Improving Data for Feeding the Curve Fitter

This section demonstrates the use of a spreadsheet to manipulate the data collected in the previous section

to get a more accurate curve fit. The data is presented in a format compatible with the curve fitter software.

6.4.1 Understanding the Data and Data Format

The final data can be collected in a spreadsheet. An example of the spreadsheet is shown in Figure 16. Steps

are provided to the left to describe the process.

The NTC configuration section is shown in Figure 17. Values for Vref, Nbit and Ifs are internal parameters of

the IC that do not change. The beta and initial resistance at the initial temperature can be changed.

The NTC code can be generated using Equation 22. If temperature is specified in the system, then:

where

Temperature T1 and T0 are in degrees Kelvin

NTC Beta

4334 Vref

1.25

ENTER DIM VALUES (BwDim, RedDim), CURRENTS (I_bw, I_red)AND NTC TEMPERATURE (Tntc) in deg. C

NTC T0 °C

25 Nbit

8

NTC code IS COMPUTED FROM Tntc AND NTC PARAMETERS

NTC Rs at T0

100000 Ifs

8.00E-05

Series R

14000

іNTC PARAMETERS

enter

enter

љ

љ

BwDim

I_bw (A)

ї enter

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0.1

0.068

0.2

0.131

Tamb(room)

computed

ќ

enter

ќ

0.3

0.190

ї enter

5.00

0.042

0.078

0.110

0.138

0.161

0.180

0.196

0.207

0.216

0.221

0.09

0.16

0.23

0.28

0.33

0.37

0.40

0.42

0.44

0.45

0.4

0.246

15.00

0.044

0.083

0.116

0.145

0.170

0.190

0.206

0.218

0.227

0.233

0.09

0.17

0.24

0.30

0.35

0.39

0.42

0.45

0.46

0.48

0.5

0.297

25.00

0.046

0.087

0.122

0.153

0.179

0.200

0.217

0.230

0.239

0.245

0.09

0.18

0.25

0.31

0.36

0.41

0.44

0.47

0.49

0.50

0.6

0.344

45.00

0.049

0.091

0.128

0.160

0.187

0.210

0.228

0.241

0.251

0.257

0.10

0.19

0.26

0.33

0.38

0.43

0.46

0.49

0.51

0.53

0.7

0.386

65.00

0.051

0.096

0.135

0.168

0.197

0.220

0.239

0.253

0.264

0.270

0.10

0.20

0.28

0.34

0.40

0.45

0.49

0.52

0.54

0.55

0.8

0.425

85.00

0.053

0.101

0.142

0.177

0.207

0.231

0.251

0.266

0.277

0.284

0.11

0.21

0.29

0.36

0.42

0.47

0.51

0.54

0.57

0.58

0.9

0.460

1

0.490

Tamb(room)

enter

ќ

5.00

5.20

7.40

9.60

11.80

14.00

16.20

18.40

20.60

22.80

25.00

15.00

15.20

17.40

19.60

21.80

24.00

26.20

28.40

30.60

32.80

35.00

25.00

25.20

27.40

29.60

31.80

34.00

36.20

38.40

40.60

42.80

45.00

45.00

45.20

47.40

49.60

51.80

54.00

56.20

58.40

60.60

62.80

65.00

65.00

65.20

67.40

69.60

71.80

74.00

76.20

78.40

80.60

82.80

85.00

85.00

85.20

87.40

89.60

91.80

94.00

96.20

98.40

100.60

102.80

105.00

computed

ќ

13.5

15.2

17.0

19.0

21.2

23.6

26.1

28.9

31.9

35.1

22.5

25.0

27.6

30.5

33.6

36.9

40.5

44.2

48.2

52.4

35.4

38.8

42.5

46.3

50.4

54.7

59.2

64.0

68.9

73.9

74.4

79.7

85.1

90.6

96.2

102.0

107.7

113.6

119.5

125.3

Hight Temp Code Limit

185

125.9

131.7

137.5

143.3

149.0

154.6

160.0

165.4

170.7

175.8

Low Temp Code Limit

12

176.2

181.1

185.9

190.6

195.0

199.3

203.4

207.4

211.2

214.8

RedDim

Ra

Ɵo (String2/String1)

Tntc[C]

NTC code

I_red

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0

0.2

0.4

0.6

0.8

1

1.2

Ra

Ɵ

o

Dim

Current Ra

Ɵos Vs Dim

Tamb = 5C

Tamb=15C

Tamb = 25C

Tamb=45C

Tamb=65C

Tamb=85C

0.000

0.100

0.200

0.300

0.400

0.500

0.600

0

0.2

0.4

0.6

0.8

1

1.2

Ou

tp

u

t Cu

rr

e

n

t (

m

A

)

Dim

Currents Vs Dim

I_BW

I_RED 5C

I_RED 15C

I_RED 25C

I_RED 45C

I_RED 65C

I_RED 85C

Step 1:

Enter NTC

Configuration

Step 4:

Enter Current Ratio

vs Dim and Temp

Step 5:

Enter Temperature or

NTC Resistance

Step 6:

Compute NTC Code

Step 3:

Enter Red Current vs

Dim and Temperature

Step 2:

Enter Blue

Current vs Dim

Figure 16. Example Spreadsheet Used to Collect Curve Fitting Data

NTC Beta

4334 Vref

1.25

NTC T0 °C

25 Nbit

8

NTC Rs at T0

100000 Ifs

8.00E-05

Series R

14000

Does Not Change

Figure 17. NTC Specification from Example Spreadsheet

NTC

CODE

4M

R

Series

R

T0

e

1

T1

-------

1

T0

-------

–

+

--------------------------------------------------------------------------

=

[Eq. 22]