6 data improvements for the curve fitting process, 1 typical light engine system specifications, An374 – Cirrus Logic AN374 User Manual

Page 21

AN374

AN374REV2

21

6 Data Improvements for the Curve Fitting Process

The curve-fitting process consists of translating a typical LED system specification into polynomial gain equations

that the curve fitter can then calculate the required current for a given dim and NTC reading. The gains can be used

in conjunction with the design of the power stage to complete a system design for a CS1630/31-based LED driver.

6.1 Typical Light Engine System Specifications

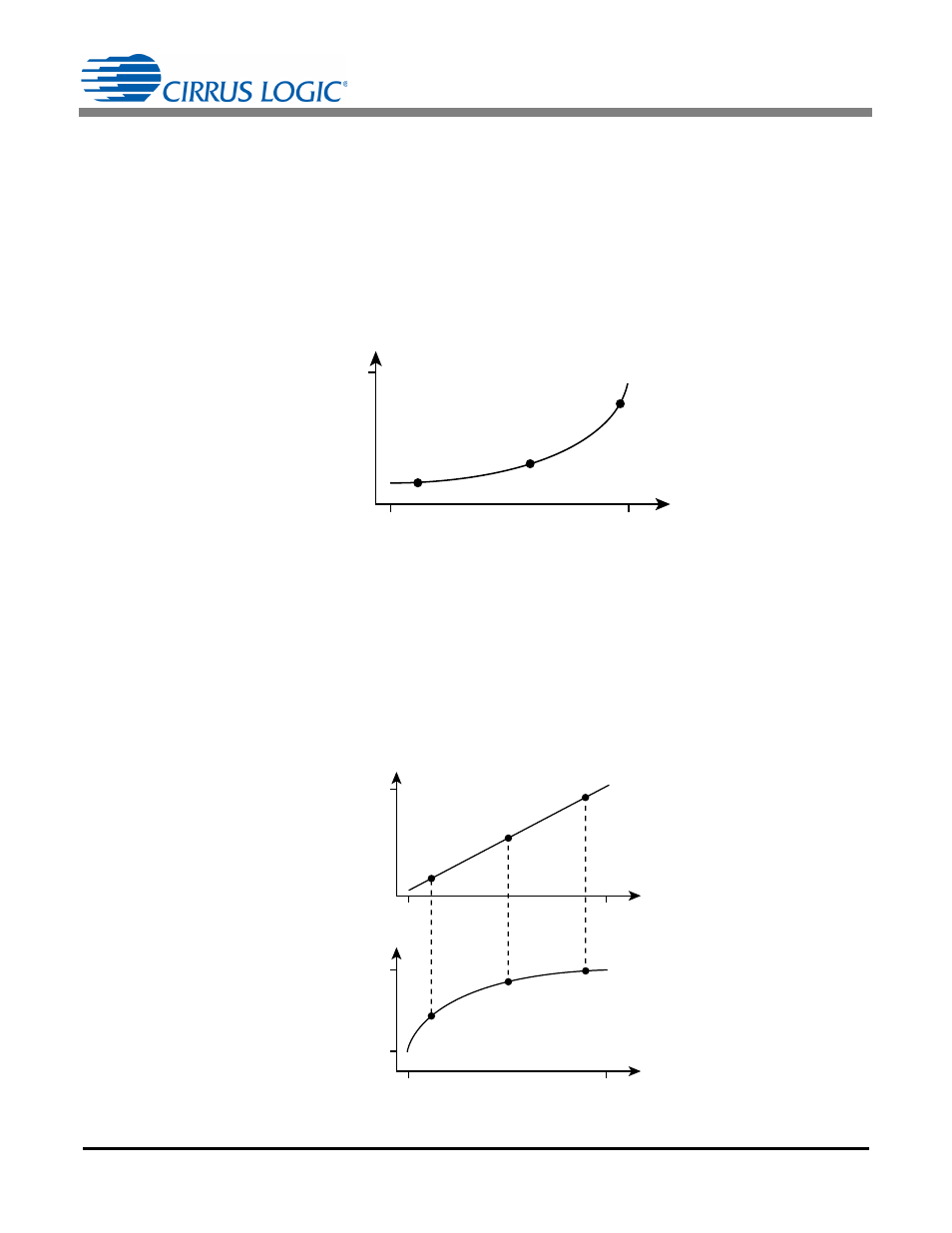

A typical light engine system specification is concisely captured in Figure 11. It is essentially a plot of the target

lumen output at a given target color correlated temperature (CCT). Points 1, 2, and 3 are some data points of

interest. These points have been used to define system behavior. The graph shows that the behavior is

expected to be constant across the entire operating temperature of the driver. If the behavior over temperature

were different, it can be represented as separate parameterized curves using the same axis.

6.2 Translation into Input Specifications for Calculating Color Gains

The light engine specifications above need to be translated into typical driver specifications that can be used

by the second stage of the CS1630/31 based driver.

Step 1)

Introduction of an independent dim axis

The curve fitter polynomial equation is an equation across dim and NTC temperature. The independent dim

axis can be introduced as shown in Figure 12. At this point, the specifications can be redefined as needed to

find a trajectory the light engine needs to traverse in terms of CCT and brightness when the input dim level to

the system changes.

1600

650

1

2

3

2700

Brightness (lm)

CCT (K)

Figure 11. Typical LED Light Engine Specifications

0.02

650

Brightness (lm)

1.0

1

0.02

2700

1600

CCT

(K)

Dim

1.0

2

3

Figure 12. Light Engine Specifications Translated to an Imaginary Dim Axis