WIKA IS-21-F User Manual

Page 8

2132926.07 GB/D/F/E 03/2010

14 WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio IS-2X

2132926.07 GB/D/F/E 03/2010

15

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio IS-2X

Specifications

Model IS-20-S, IS-21-S, IS-20-F, IS-21-F, IS-20-H

Pressure ranges *

)

IS-2X-S, IS-2X-F

bar

0.1

0.16 0.25 0.4

0.6

1

1.6

2.5

4

6

10

16

Over pressure safety

IS-2X-S,IS-2X-F

bar

1

1.5

2

2

4

5

10

10

17

35

35

80

Burst pressure

IS-2X-S, IS-2X-F

bar

2

2

2.4

2.4

4.8

6

12

12

20.5 42

42

96

Pressure ranges *

)

IS-2X-S, IS-2X-F

bar

25

40

60

100 160 250 400

600

1000

1)

Over pressure safety

IS-2X-S,IS-2X-F

bar

50

80

120 200 320 500 800

1200

1500

Burst pressure

IS-2X-S, IS-2X-F

bar

96

400 550 800 1000 1200 1700

2)

2400

2)

3000

Pressure ranges for IS-20-H see additional operating

instructions 11126418 High pressure

{Vacuum, gauge pressure, compound range, absolute pressure are available}

1)

Only Model IS-20-S, IS-20-F.

2)

For model IS-21-S, IS-21-F: the value specified in the table applies only when

sealing is realised with the sealing ring underneath the hex.

Otherwise max. 1500 bar applies.

Materials

Wetted parts

»

Model IS-20-S, IS-20-F,

IS-20-H *

)

Stainless steel

»

Model IS-21-S, IS-21-F

Stainless steel

O-ring: NBR {FPM/FKM or EPDM}

Case

Stainless steel

Internal transmission fluid

3)

Synthetic oil {Halocarbon oil for oxygen applications}

3)

Not for IS-20-S, IS-20-F with pressure ranges > 25 bar and IS-20-H.

Power supply U+

DC V

»

Model IS-2X-S, IS-20-H

10 ...

30

»

Model IS-2X-F,

IS-20-H with field case

11 ...

30

Signal output and

R

A

in Ohm

4 … 20 mA, 2-wire

maximum ohmic load R

A

Model IS-2X-S

R

A

≤ (U+ – 10 V) / 0.02 A - (length of flying leads in m x 0.14 Ohm)

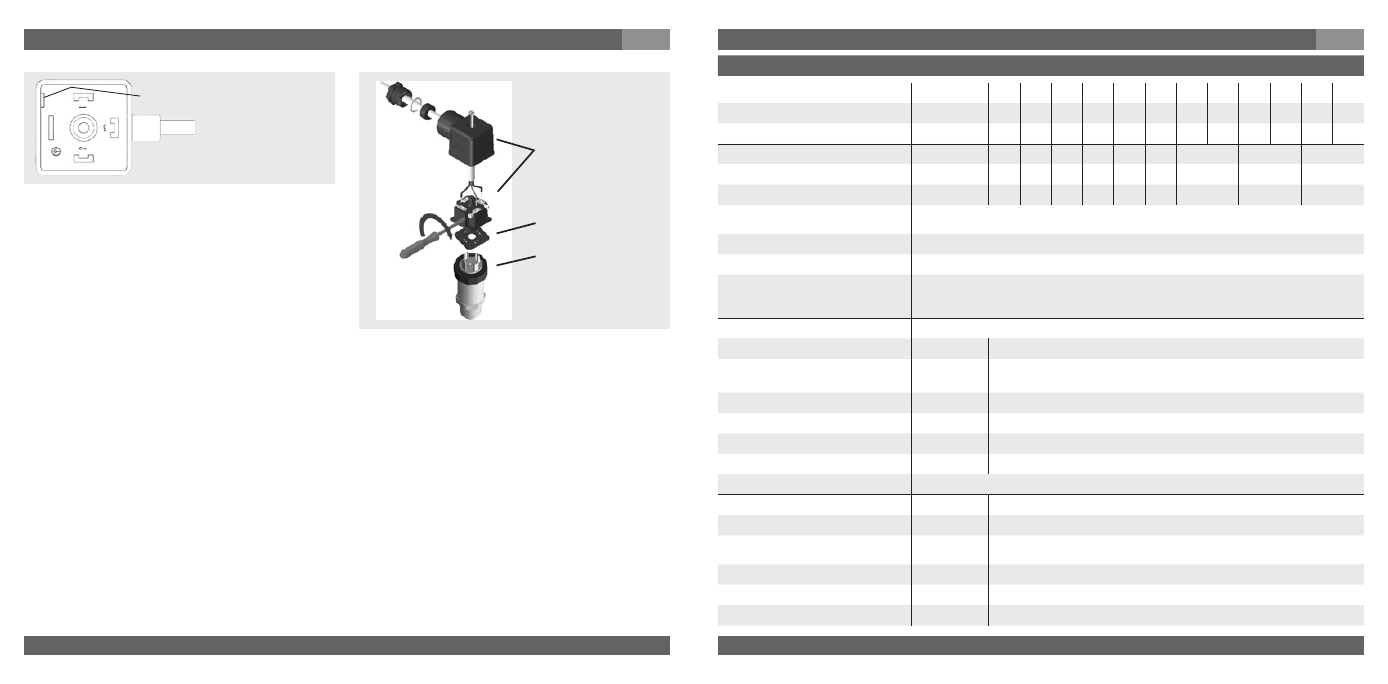

(D) Mounting hole

1. Loosen the screw (1).

2. Loosen the cable gland (2).

3. Pull the angle housing (5), with the

terminal block (6) inside, away from the

instrument.

4. Using the head of a small screwdriver in

the mounting hole (D), lever the terminal

block (6) out of the angle housing (5).

In order not to damage the sealing of the angle housing, do not try to push the terminal

block (6) out using the screw hole (1) or the cable gland (2).

5. Ensure that the conductor outer diameter you select is matched to the angle housing’s

cable gland. Slide the cable through the cable gland nut (2), washer (3), gland seal (4) and

angle housing (5).

6. Connect the flying leads to the screw terminals on the terminal block (6) in accordance

with the pin-assignment drawing.

7. Press the terminal block (6) back into the angle housing (5).

8. Tighten the cable gland (2) around the cable. Make sure that the sealing isn’t damaged

and that the cable gland and seals are assembled correctly in order to ensure ingress

protection.

9. Place the flat, square gasket over the connection pins on the top of the instrument

housing.

10. Slide the terminal block (6) onto the connection pins.

11. Secure the angle housing (5) and terminal block (6) to the instrument with the screw (1).

Assembly of L-connector DIN EN 175301-803

(6)

(5)

(1)

(2)

(3)

(4)

Clamping nut,

Male connector,

Case with

pressure connection

Sealing

Female

connector

7. Starting, operation

GB

7. Starting, operation

GB