Goulds Pumps 3298 - IOM User Manual

Page 86

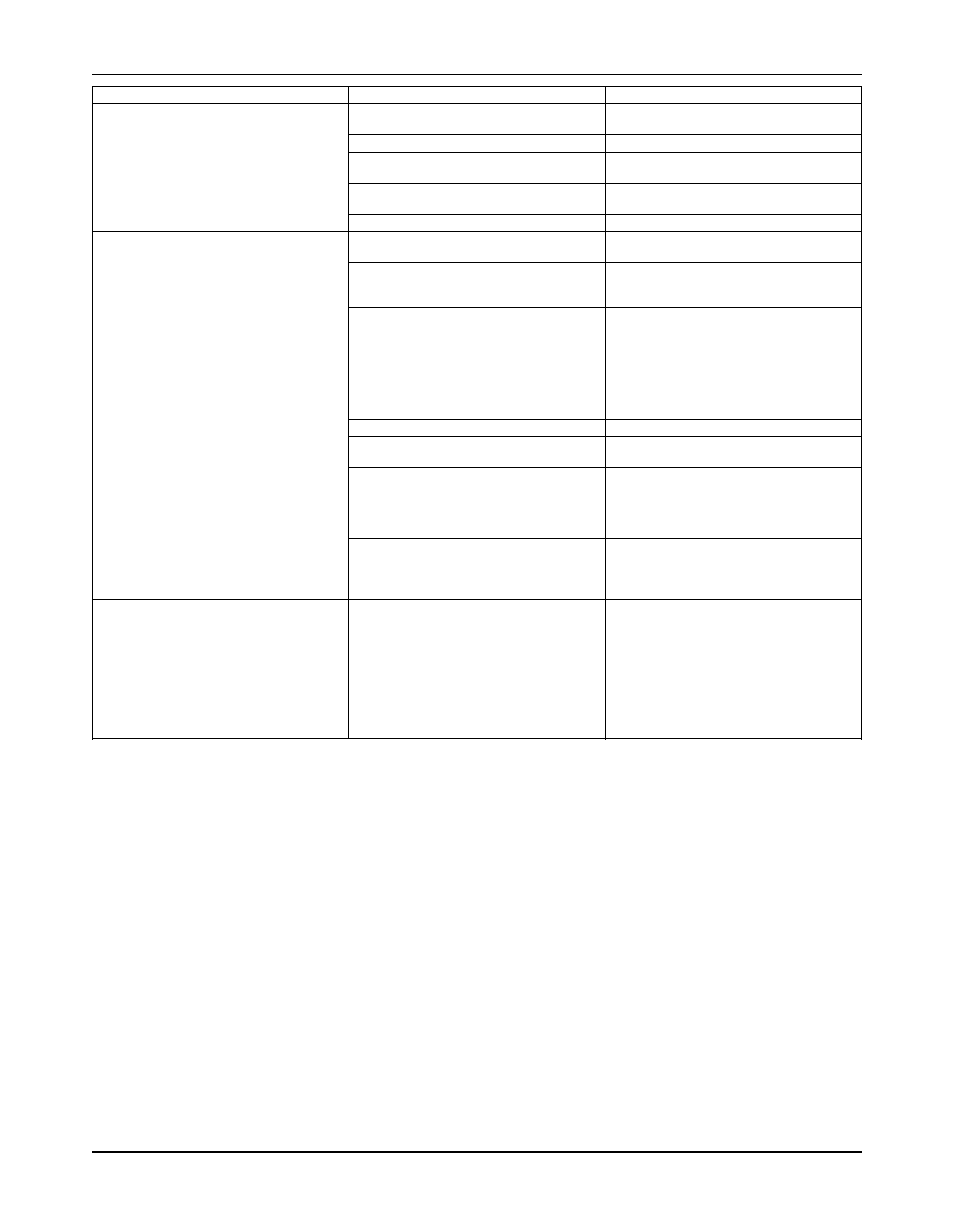

Troubleshooting

Symptom

Cause

Remedy

The motor requires excessive power.

The head is lower than the rating and the

Install a throttle valve.

pump has too much liquid.

The liquid is heavier than expected.

Check the specific gravity and viscosity.

The head is higher than the rating, which

Check the impeller diameter.

is at capacity.

The rotating parts are binding or are

Check the internal wearing parts for prop-

severely worn.

er clearances.

The motor rotation is incorrect.

Correct the wiring.

The condition monitoring device shuts

The sleeve and thrust bearings are dam-

Replace as required.

down the pump.

aged.

There is a plugged recirculation circuit.

Disassemble and remove the blockage.

Then determine and correct the cause of

the blockage.

There is recirculation liquid vaporization.

Correct all of these as necessary:

• Check the actual liquid temperature

versus the design temperature.

• Check the actual NPSH available

versus the design.

• Check the minimum flow require-

ment for the pump size.

The containment shell is damaged.

Replace as required.

The magnets are de-coupling.

Check the temperature and viscosity of

the pumped fluid.

The pump is running dry.

• Check the control device for proper

operation.

• Check the suction line for blockage.

• Reprime the pump.

There is excessive motor power.

The system head is lower than the rating

and pumps too much liquid.

Check the rotating parts for binding and

wear. The liquid is heavier than expected.

There is a significant increase in heat

There is either insufficient lubrication or

• Install a dry run protection device like

generation.

you ran the liquid lubricated bearing sur-

a power monitor.

faces dry. The lack of cooling flow through

• Modify the process system or con-

the pump also causes significant in-

trols in order to eliminate the dry run

creases in bearing temperature. This tem-

operation.

perature increase causes damage to the

• Change the bearing material to

surrounding parts. See the Increase in

DryGuard™ coated silicon carbide if

heat generation figure for details.

silicon carbide bearings were initially

installed in the pump.

84

3298 Family Installation, Operation, and Maintenance Manual