Piping checklists, General piping checklist – Goulds Pumps 3298 - IOM User Manual

Page 33

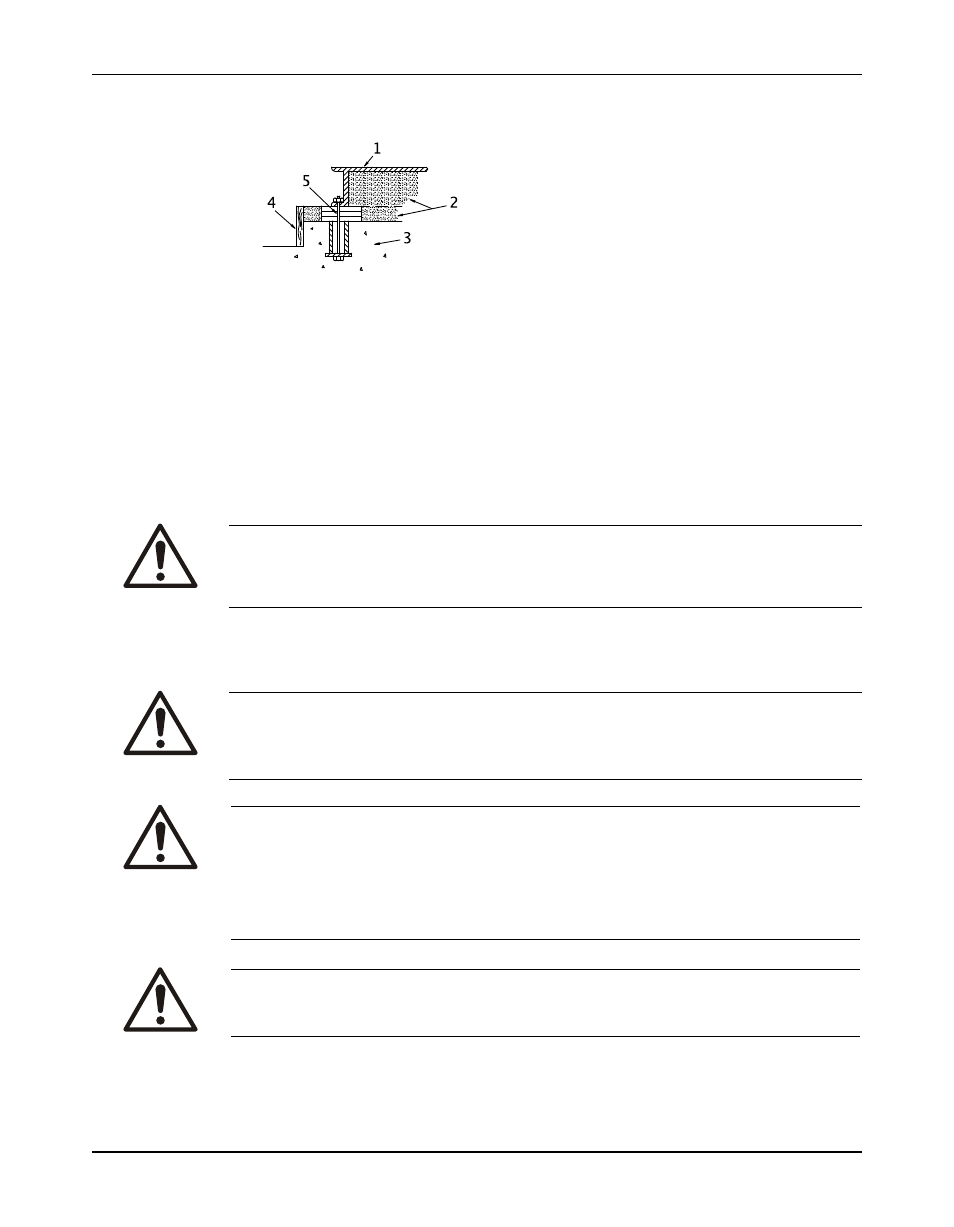

Installation

6. Fill the remainder of the baseplate with grout, and allow the grout to set for at least 48

hours.

1. Baseplate

2. Grout

3. Foundation

4. Dam

5. Bolt

7. Tighten the foundation bolts.

8. Recheck the alignment.

Piping checklists

Fastening

WARNING:

• Only use fasteners of the proper size and material.

• Replace all corroded fasteners.

• Make sure that all fasteners are properly tightened and that there are no missing fasteners.

General piping checklist

Precautions

WARNING:

• The heating of water and other fluids causes volumetric expansion. The associated forces can cause

the failure of system components and the release of high-temperature fluids. In order to prevent this,

install properly sized and located compression tanks and pressure-relief valves. Failure to follow

these instructions can result in serious personal injury or death, or property damage.

CAUTION:

• Never draw piping into place by using force at the flanged connections of the pump. This can

impose dangerous strains on the unit and cause misalignment between the pump and driver. Pipe

strain adversely affects the operation of the pump, which results in physical injury and damage to

the equipment.

• Vary the capacity with the regulating valve in the discharge line. Never throttle the flow from the

suction side. This action can result in decreased performance, unexpected heat generation, and

equipment damage.

CAUTION:

Flange loads from the piping system, including those from the thermal expansion of the piping, must not

exceed the limits of the pump. Deformation can result in contact with rotating parts, which can result in

excess heat generation, sparks, and premature failure.

3298 Family Installation, Operation, and Maintenance Manual

31