Reassembly, Reassembly precautions – Goulds Pumps 3298 - IOM User Manual

Page 66

Maintenance

• Replace the magnet assembly if it was exposed to pumped fluid.

• Inspect magnets for proper bonding to the carrier.

Bearing frame - frame-mounted version only

• Inspect the frame and frame foot for cracks.

• Inspect the frame and rub ring for corrosion or pitting if parts have been exposed to

pumped fluid.

• Inspect the bearing frame bores. The maximum acceptable bore is:

• S group: 2.4419 in. (62.024 mm)

• M and L groups: 2.8353 in. (72.017 mm)

• Inspect the ball bearings for contamination and damage.

• Inspect the bearing end cover for cracks and pits.

• Make sure that the gasket surface is clean.

• Replace the lip seal.

• Inspect the shaft for cracks and scoring.

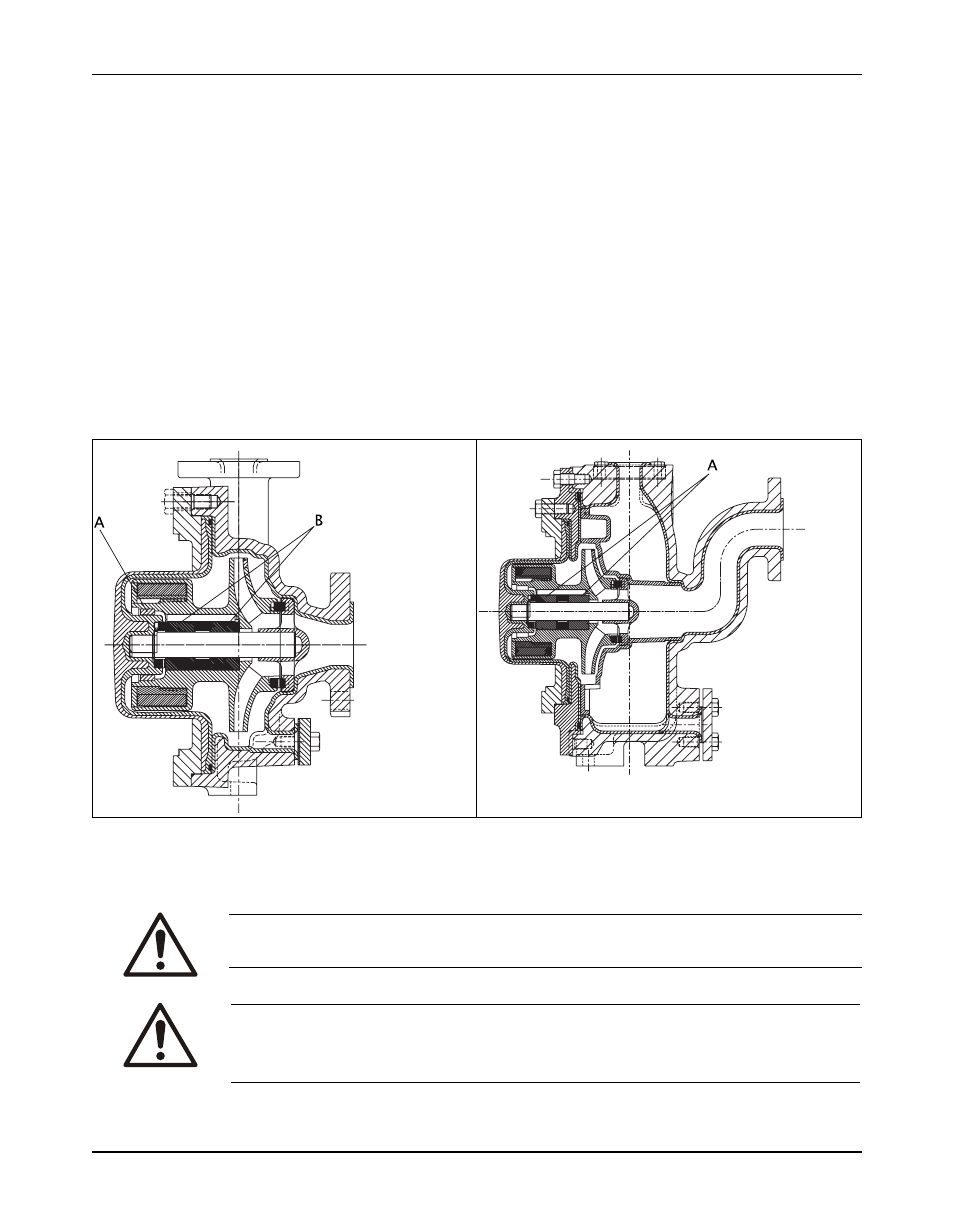

Inspection locations

Reassembly

Reassembly precautions

WARNING:

Explosion risk. Rubbing could lead to excess heat generation and sparks. Rotate the shaft by hand to

make sure it rotates smoothly and that there is no rubbing.

CAUTION:

• The magnets in this unit are extremely powerful. Beware of serious injury to fingers and hands.

Keep magnetic drive components and magnetic tools apart by a minimum of 3 ft (1 m).

• Use a non-magnetic socket and wrench.

64

3298 Family Installation, Operation, and Maintenance Manual