Baseplate-mounting procedures, Prepare the baseplate for mounting, Install the baseplate using shims or wedges – Goulds Pumps 3298 - IOM User Manual

Page 22

Installation

Baseplate-mounting procedures

Prepare the baseplate for mounting

1. Remove all the attached equipment from the baseplate.

2. Clean the underside of the baseplate completely.

3. If applicable, coat the underside of the baseplate with an epoxy primer.

Use an epoxy primer only if you used an epoxy-based grout.

4. Remove the rust-proofing coat from the machined mounting pads using an appropriate

solvent.

5. Remove water and debris from the foundation-bolt holes.

Install the baseplate using shims or wedges

Required tools:

• Two sets of shims or wedges for each foundation bolt

• Two machinist's levels

• Baseplate-leveling worksheet

This procedure is applicable to cast iron and fabricated steel baseplates.

1. Remove water and debris from the anchor bolt holes and sleeves.

2. If you use sleeve-type bolts, fill the bolt sleeves with packing material or rags to prevent

grout from entering the bolt holes.

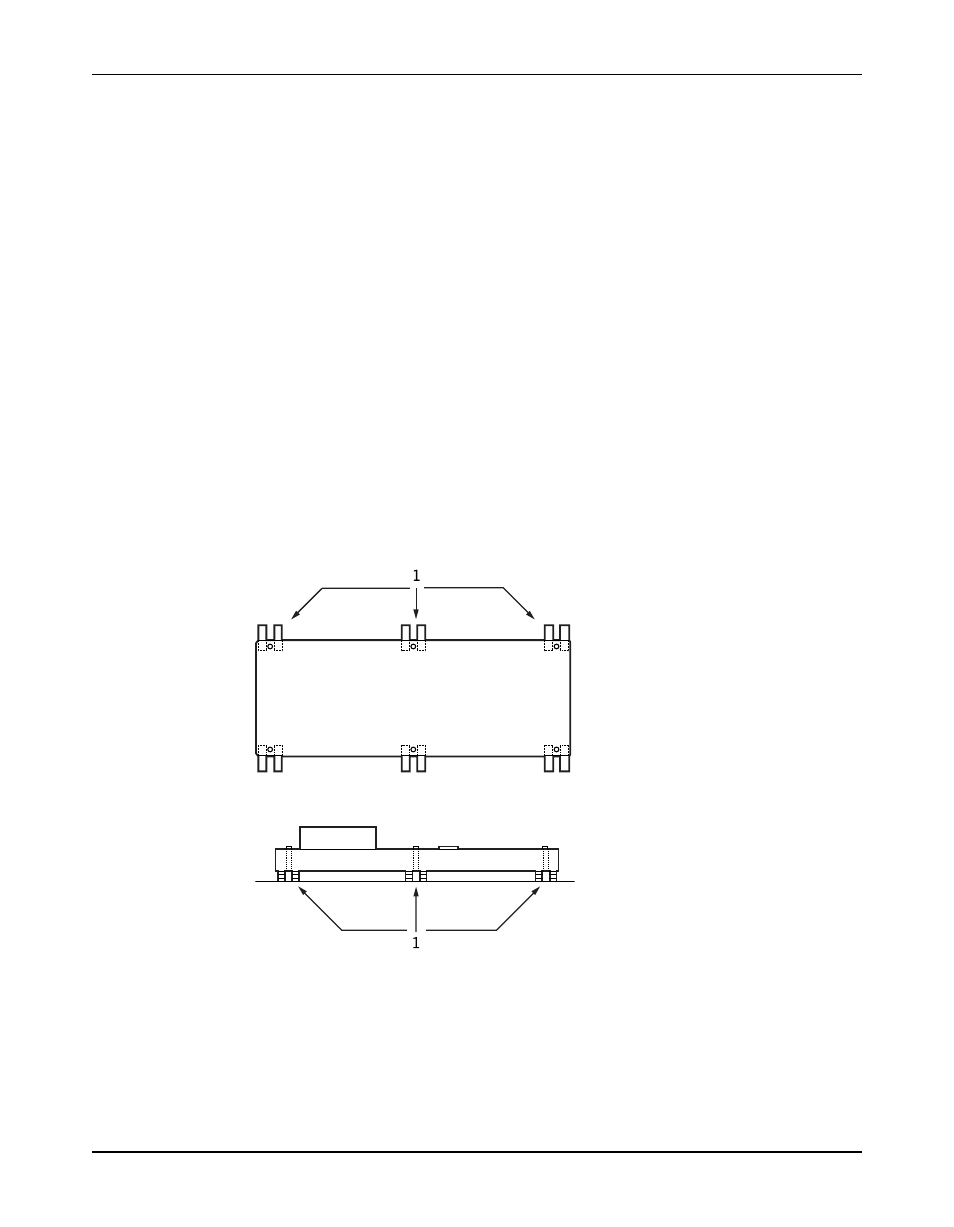

3. Put the sets of wedges or shims on each side of each foundation bolt.

Make sure that the wedges extend 0.75 in. (19 mm) to 1.5 in. (38 mm) above the foundation

to provide adequate space for grouting. The wedges will provide adequate support for the

baseplate after it is grouted.

1. Shims or wedges

Figure 7: Top view

1. Shims or wedges

Figure 8: Side view

4. Lower the baseplate carefully onto the foundation bolts.

5. Put the machinist's levels across the mounting pads of the driver and the mounting pads of

the pump.

20

3298 Family Installation, Operation, and Maintenance Manual