Minimum continuous recommended flow – Goulds Pumps 3298 - IOM User Manual

Page 51

Commissioning, Startup, Operation, and Shutdown

CAUTION:

• Immediately observe the pressure gauges. If discharge pressure is not quickly attained, stop the

driver, reprime, and attempt to restart the pump.

• Observe the pump for vibration levels, bearing temperature, and excessive noise. If normal levels

are exceeded, shut down the pump and resolve the issue.

• On pure or purge-oil mist-lubricated units, remove the viewing port plugs to verify that oil mist

flowing properly. Replace the plugs.

• On frame mounted units, ensure that the oil level is correct prior to starting pump. Close coupled

pumps do not have oil lubricated bearings.

• Ensure all flush and cooling systems are operating correctly prior to starting pump.

• Continuous operation against a closed discharge valve will cause the pump to overheat.

Overheating the magnetic drive assembly will weaken or ruin the magnets.

Before you start the pump, you must perform these tasks:

• Open the suction valve.

• Open any recirculation or cooling lines.

1. Fully close or partially open the discharge valve, depending on system conditions.

2. Start the driver.

3. Slowly open the discharge valve until the pump reaches the desired flow.

4. Immediately check the pressure gauge to ensure that the pump quickly reaches the correct

discharge pressure.

5. If the pump fails to reach the correct pressure, perform these steps:

a) Stop the driver.

b) Prime the pump again.

c) Restart the driver.

6. Monitor the pump while it is operating:

a) Check the pump for bearing temperature, excessive vibration, and noise.

b) If the pump exceeds normal levels, then shut down the pump immediately and correct

the problem.

A pump can exceed normal levels for several reasons. See Troubleshooting for

information about possible solutions to this problem.

7. Repeat steps 5 and 6 until the pump runs properly.

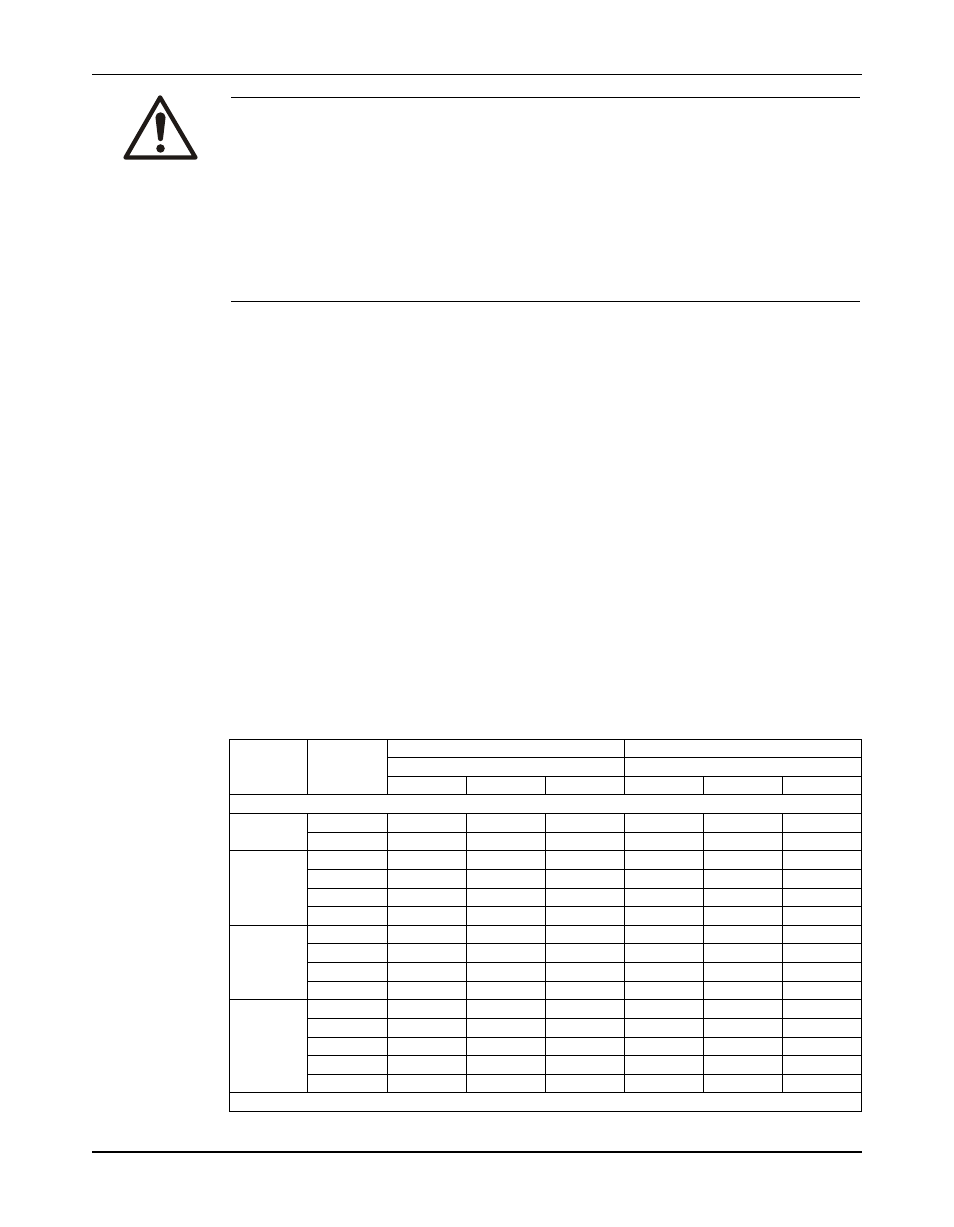

Minimum continuous recommended flow

Group

Pump size 60 Hertz

50 Hertz

GPM

m3/hr

3600

1800

1200

3000

1500

1000

3298

XS

1 x 1.5 - 5

1

0.5

—

0.2

0.1

—

1½ x 2 - 6

5

3

—

1

0.5

—

S

1 x 1.5 - 6

5

3

2

2

1

0.5

1 x 1.5 - 8

15

8

4

3

2

1

1½ x 3 - 7

20

10

6

5

2

1

2 x 3 - 6

30

15

8

6

3

1

M

1½ x 3 - 8

30

15

8

6

3

1

2 x 3 - 8

50

9

5

9

2

1

3 x 4 - 7

80

13

9

18

9

6

1 x 2 - 10

30

5

3

5

3

2

L

1½ x 3 - 10

60

30

20

11

5

4

2 x 3 - 10

100

50

33

19

10

6

3 x 4 - 10G

175

90

60

33

16

11

3 x 4 - 10H

-

90

30

—

17

3

4 x 6 - 10

-

475

5

325

5

—

95

5

55

5

SP3298

3298 Family Installation, Operation, and Maintenance Manual

49