Preassembly inspections – Goulds Pumps 3298 - IOM User Manual

Page 64

Maintenance

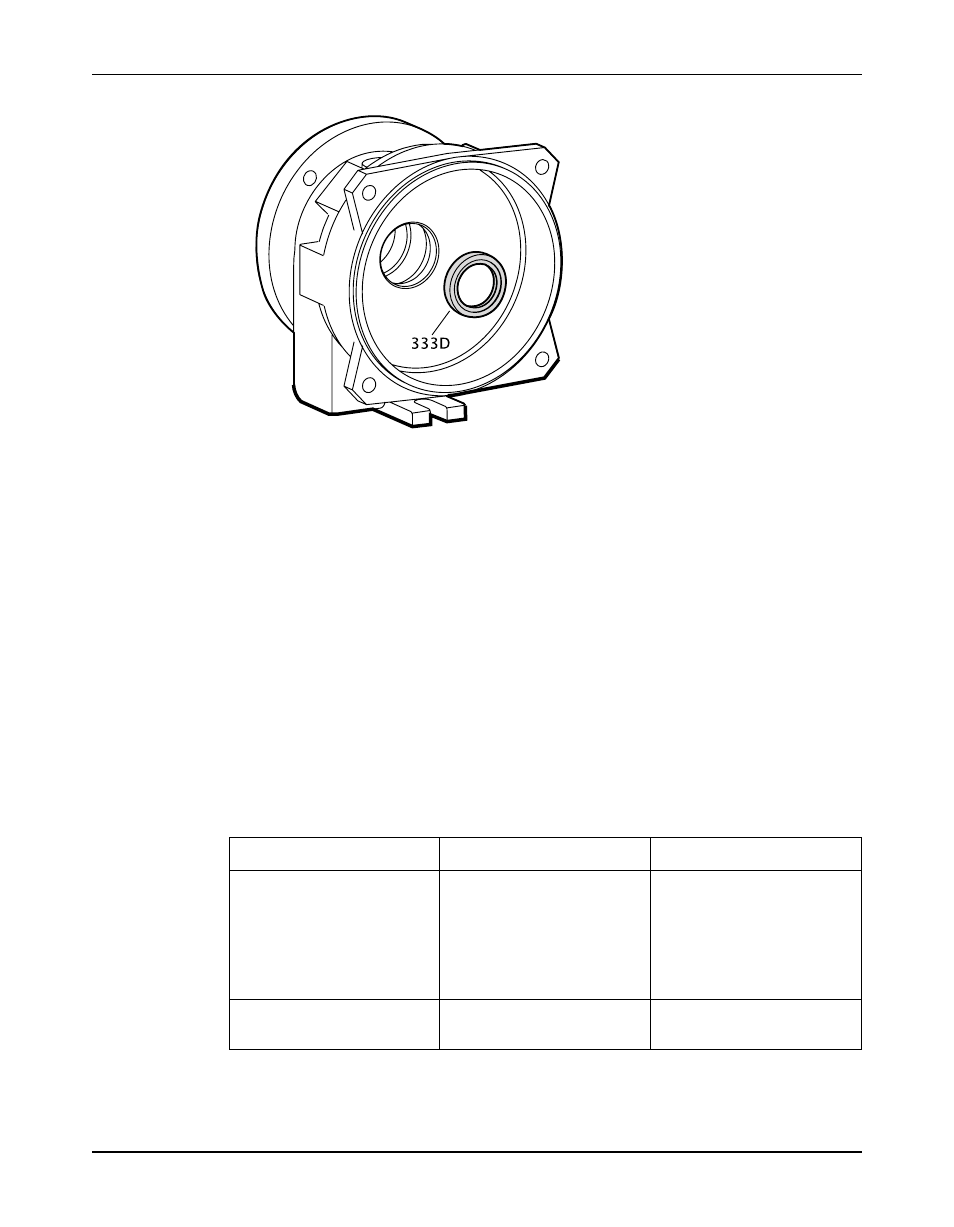

13. Remove the lip seal (333D).

Figure 34: Lip seal removal

Preassembly inspections

Inspect pump parts according to the following criteria before reassembly in order to make sure

the pump will run properly. Replace any part that does not meet the required criteria.

Casing

Inspect the casing for excessive wear, abrasive damage, cuts, or a loose liner.

Spider bearing

Inspect the spider bearing for cracks, chips, or scoring.

Impeller

• Inspect the leading and trailing edges of the vanes for erosion damage.

• Inspect the impeller for cracks and grooves in excess of 0.03 in. (0.75 mm).

• Check the impeller for blocked passages.

Back wear ring

Inspect the back wear ring according to the clearances in the Back wear ring clearances table.

Table 7: Back wear ring clearances

Size

New clearance inches

Replace at inches (millimeters)

(millimeters)

1 x 1½-5

No wear ring

No wear ring

1½ x 2-6

1 x 1½-6

1 x 1½-7

1 x 1½-8

2 x 3-6

1½ x 3-8

1 x 1½-8

3 x 4-7

0.060 - 0.066 (1.52 - 1.68)

0.090 (2.3)

2 x 3-8

1 x 2-10

62

3298 Family Installation, Operation, and Maintenance Manual