Bearing lubrication, Lubricating oil requirements – Goulds Pumps 3298 - IOM User Manual

Page 47

Commissioning, Startup, Operation, and Shutdown

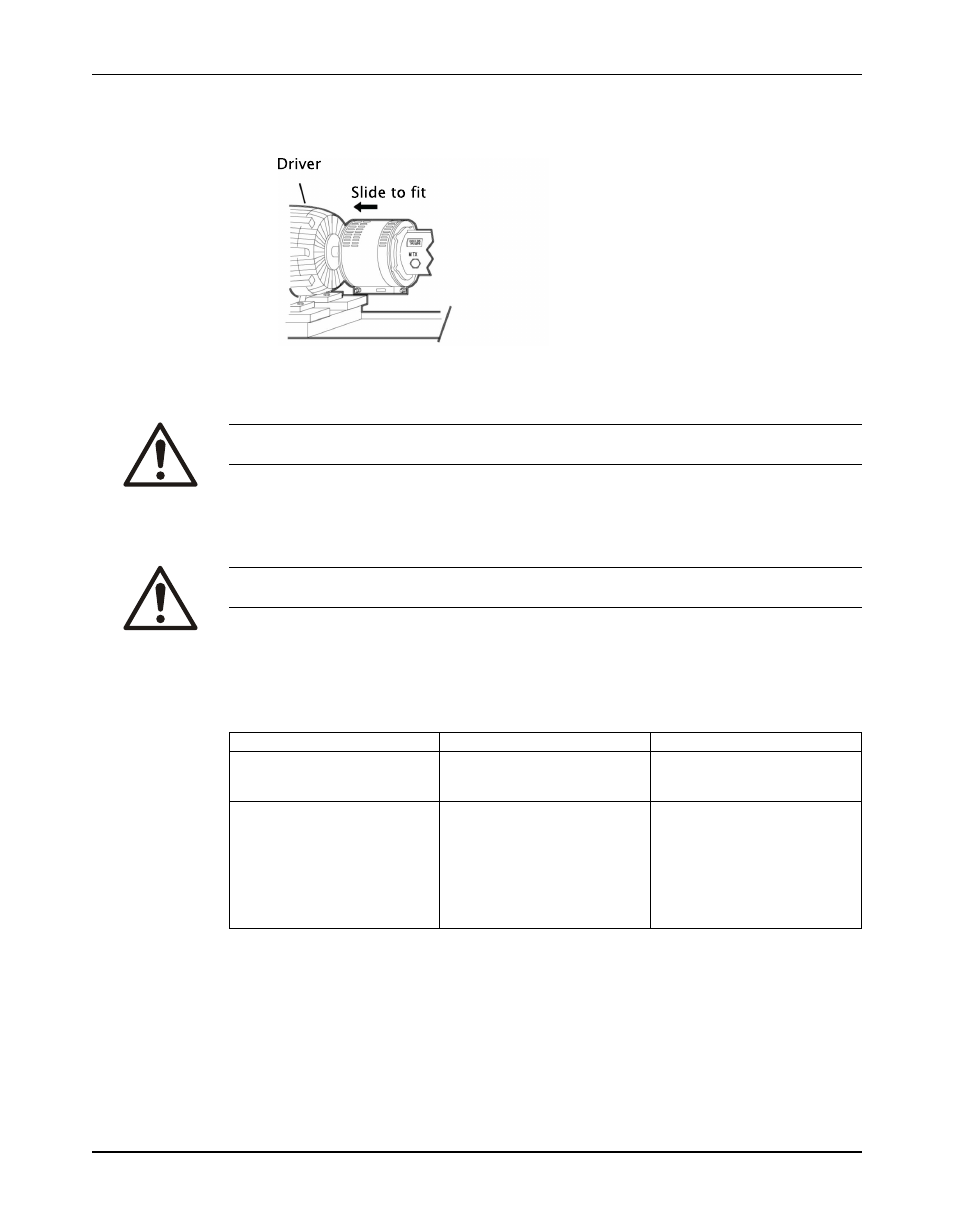

9. Slide the driver-half of the coupling guard towards the motor so that the coupling guard

completely covers the shafts and coupling.

10. Use a nut, a bolt, and two washers to secure the coupling guard halves together.

11. Tighten all nuts on the guard assembly.

WARNING:

Never operate the pump without the coupling guard correctly installed.

Bearing lubrication

WARNING:

Pumps are shipped without oil. Oil-lubricated anti-friction bearings must be lubricated at the job site.

These bearing lubrication sections list different pumped-fluid temperatures. If your pump is

ATEX certified and your pumped-fluid temperature exceeds the permitted temperature values,

then consult your ITT representative.

Lubrication requirements

Pump type

Pump model

Requirements

Close coupled

3298

Close coupled pumps do not have

bearings which require lubrication.

SP3298

V3298

Frame mounted

3298

• Oil level is measured through

SP3298

the sight glass.

• Oil level must not fall below

the center of the sight glass.

• An increase in level may be

noted after startup due to oil

circulation within the bearing

frame.

Lubricating oil requirements

Quality requirements

Use a high quality turbine oil with rust and oxidation inhibitors.

3298 Family Installation, Operation, and Maintenance Manual

45