Final piping checklist – Goulds Pumps 3298 - IOM User Manual

Page 38

Installation

Check

Explanation/comment

Checked

If increasers are used, check that they See Example: Discharge piping equipment for

are installed between the pump and

illustrations.

the check valve.

If quick-closing valves are installed in

This protects the pump from surges and water

the system, check that cushioning de- hammer.

vices are used.

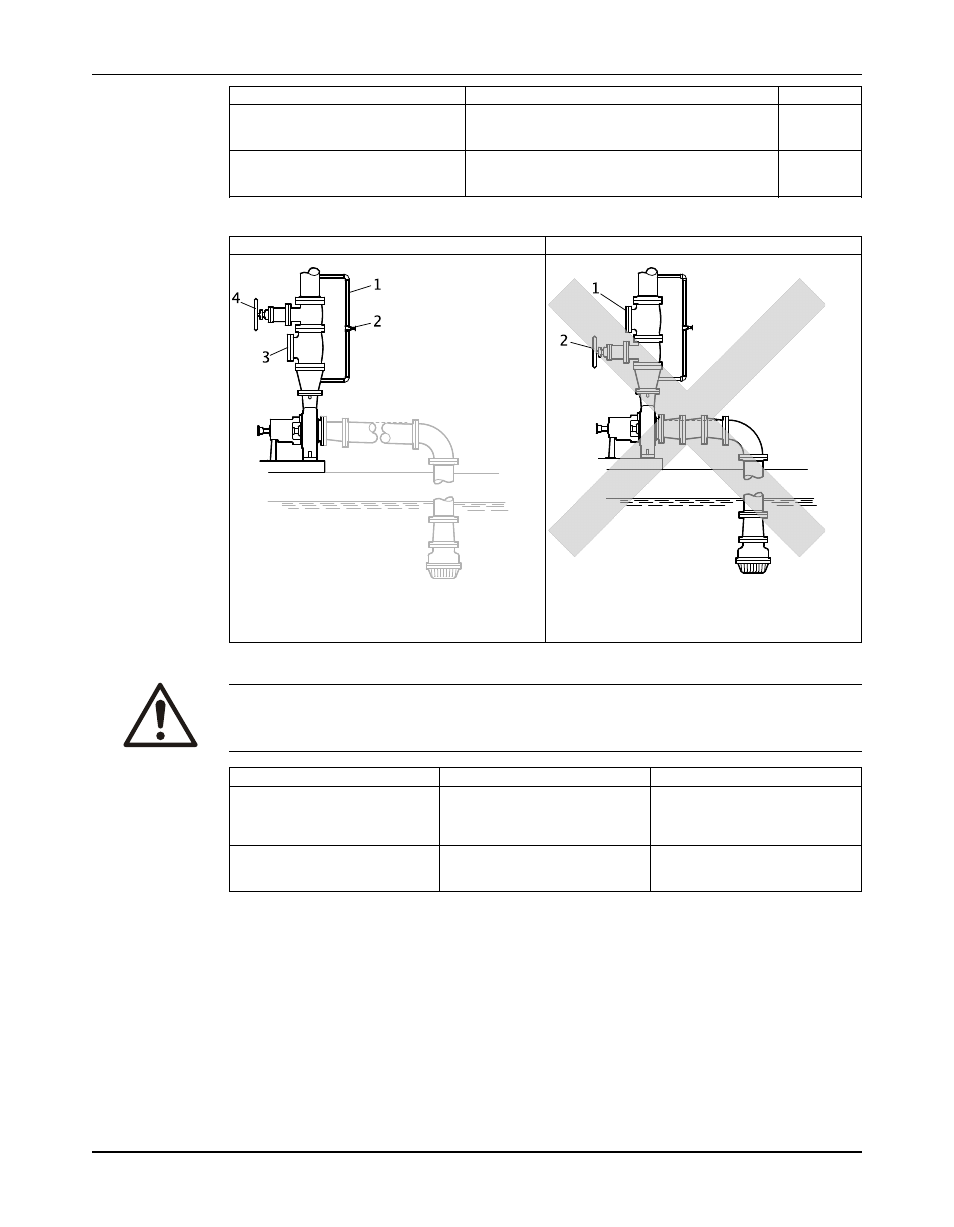

Example: Discharge piping equipment

Correct

Incorrect

1.

Check valve (incorrect position)

1.

Bypass line

2.

The isolation valve should not be positioned

2.

Shut-off valve

between the check valve and the pump.

3.

Check valve

4.

Discharge isolation valve

Final piping checklist

WARNING:

A build-up of gases within the pump, sealing system, or process piping system may result in an explosive

environment. Make sure the process piping system, pump and sealing system are properly vented prior to

operation.

Check

Explanation/comment

Checked

Check that the shaft rotates

Rotate the shaft by hand. Make

smoothly.

sure there is no rubbing that can

lead to excess heat generation or

sparks.

Re-check the alignment to make

If pipe strain exists, then correct

sure that pipe strain has not

the piping.

caused any misalignment.

36

3298 Family Installation, Operation, and Maintenance Manual