Acceptable oil for lubricating bearings, Lubricate the bearings with oil, Pump priming – Goulds Pumps 3298 - IOM User Manual

Page 48

Commissioning, Startup, Operation, and Shutdown

Lubricating oil requirements

Bearing temperature below

Bearing temperature above

180°F (82°C)

180°F (82°C)

ISO grade

ISO viscosity grade 68

ISO viscosity grade 100

Approximate SSU at 100°F

300

470

(38°C)

DIN 51517

C68

C100

Kinematic viscosity at 105°F

68

100

(40°C) mm

2

/sec

Acceptable oil for lubricating bearings

Acceptable lubricants

Brand

Lubricant type

Chevron

GTS Oil 68

Exxon

NUTHO H68

Mobil

DTE 26 300 SSU @ 100°F (38°C)

Philips

Mangus Oil 315

MM motor oil SAE 20-20W

HDS motor oil SAE 20-20W

Shell

Tellus Oil 68

Gulf

Harmony 68

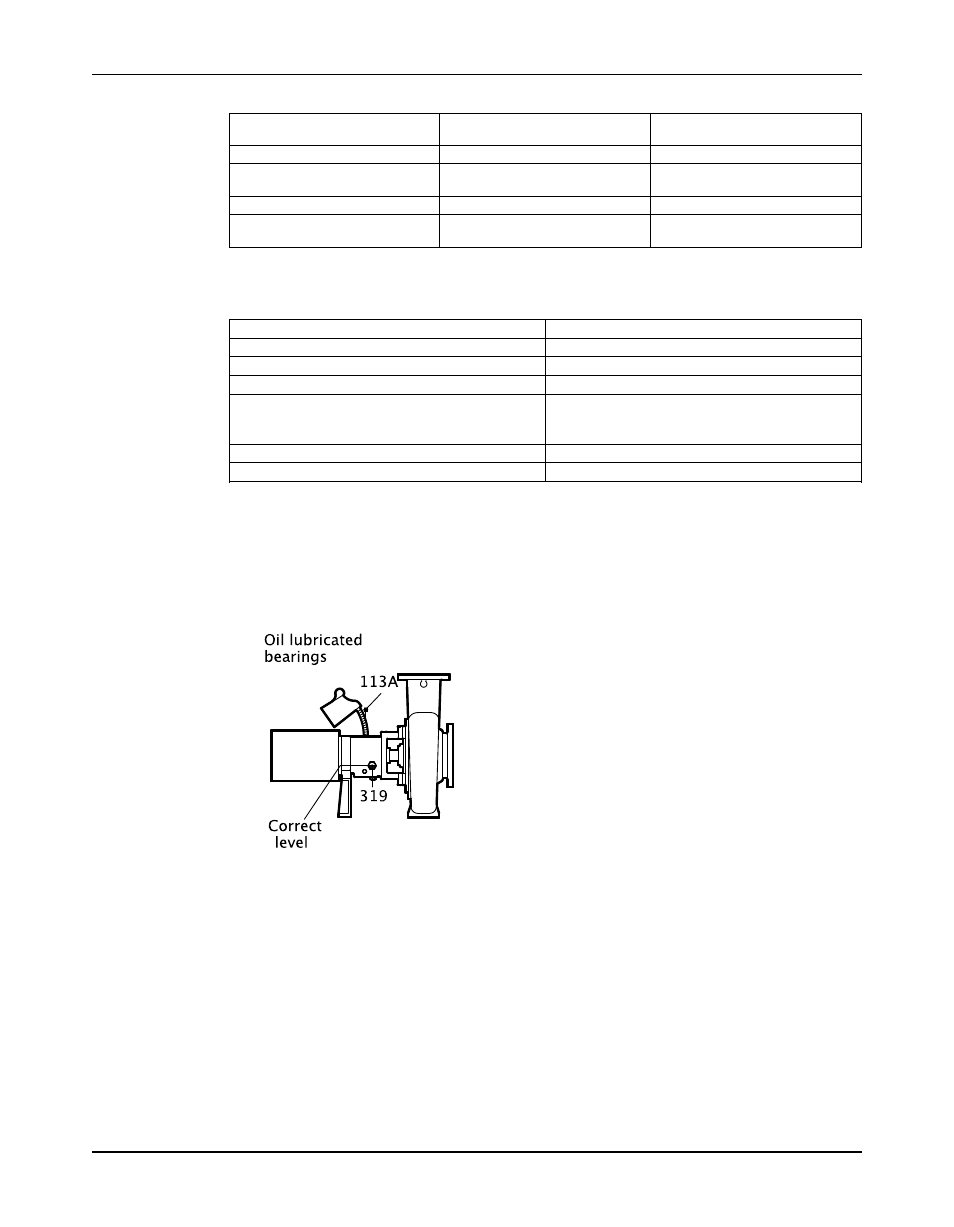

Lubricate the bearings with oil

Use a high-quality turbine oil with rust and oxidation inhibitors.

1. Remove the fill plug.

2. Fill the bearing frame with oil through the filler connection, which is located on top of the

bearing frame.

Fill the bearing frame with oil until the oil level reaches the middle of the sight glass (319).

3. Replace the fill plug.

Pump priming

Prime the pump with the suction supply above the pump

1. Slowly open the suction isolation valve.

2. Open the air vents on the suction and discharge piping until the pumped fluid flows out.

3. Close the air vents.

46

3298 Family Installation, Operation, and Maintenance Manual