Auto tune, Problems with the controller, Calibration – NOVUS Controller N1100 User Manual

Page 7

Controller N1100

NOVUS AUTOMATION

7/8

EVENT ALARM

This function makes possible to program the activation of alarms in

specific segments of a program.

For such, alarms must have their function set as “rS

rS

rS

rS “ and be

programmed in “ PE1

PE1

PE1

PE1“ to “ PE7

PE7

PE7

PE7“ according to Table 6. The number

programmed in the event prompt defines the alarms to be activated.

To configure and execute a ramp and soak program:

•

Program the tolerance value, SV, time and event.

•

If any event alarm is required program the ramp and soak event

function.

•

Set the control mode to automatic.

•

Select ramp and soak program to be executed at prompt Prn

Prn

Prn

Prn

(0 to 7)

•

Start control at the rvn

rvn

rvn

rvn prompt by selecting YES.

Before executing the program the controller waits for PV to reach the

first set point SP0 if PtoL

PtoL

PtoL

PtoL is different than zero.

Should any power failure occur the controller resumes at the

beginning of the segment it currently is.

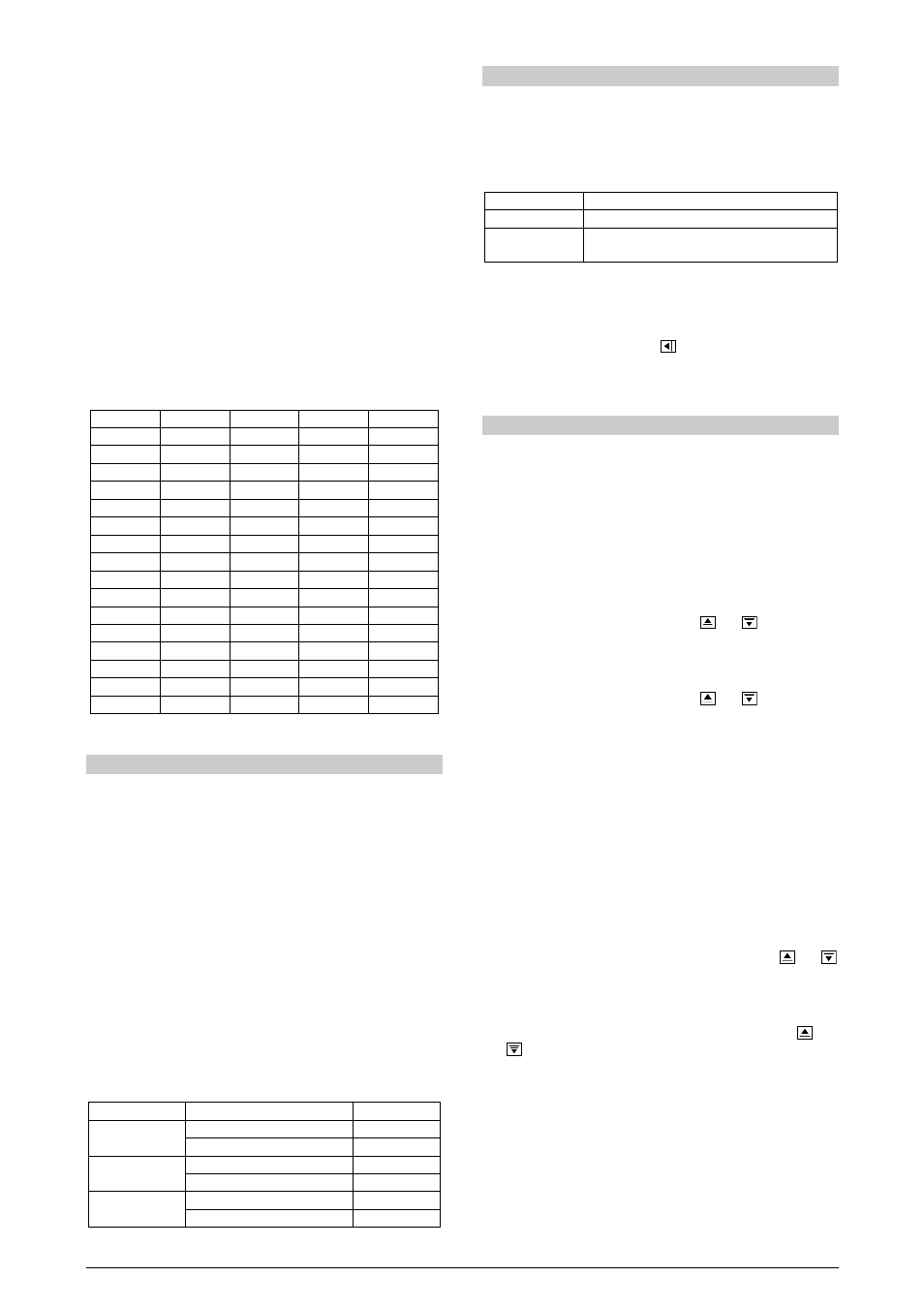

CODE

ALARM 1

ALARM 2

ALARM 3

ALARM 4

0

0

0

0

1

1

1

1

X

2

2

2

2

X

3

3

3

3

X

X

4

4

4

4

X

5

5

5

5

X

X

6

6

6

6

X

X

7

7

7

7

X

X

X

8

8

8

8

X

9

9

9

9

X

X

10

10

10

10

X

X

11

11

11

11

X

X

X

12

12

12

12

X

X

13

13

13

13

X

X

X

14

14

14

14

X

X

X

15

15

15

15

X

X

X

X

Table 5 - Event codes for ramp and soak

AUTO TUNE

During auto tune the process is controlled in ON / OFF mode at the

programmed SetPoint (SV). Depending on the process

characteristics large oscillations above and below SV may occur and

auto tuning may take several minutes to be concluded.

The recommended procedure is as follows:

•

Disable the control output at the rvn

rvn

rvn

rvn prompt by selecting NO.

•

Select auto mode operation at the Avto

Avto

Avto

Avto prompt by selecting YES.

•

Disable the ramp and soak function (select NO) and program a new

SV value other than the present PV (close to the desired set point).

•

Enable auto tuning at the Atvn

Atvn

Atvn

Atvn prompt by selecting YES.

•

Enable the control output at the rvn

rvn

rvn

rvn prompt by selecting YES.

During the auto tune procedure the soft-start function will not operate

and large oscillations will be induced around the setpoint. Make sure the

process can accept these oscillations and fast control output changes.

If auto tuning results are not satisfactory refer to Table 6 for manual

fine tuning procedure.

PARAMETER

RESPONSE

SOLUTION

Slow Response

Decrease

Proportional Band

Large Oscillation

Increase

Slow Response

Increase

Integral Rate

Large Oscillation

Decrease

Slow Response or Instability

Decrease

Derivative Time

Large Oscillation

Increase

Table 6 - Suggestions for manual tuning of PID parameters

PROBLEMS WITH THE CONTROLLER

Connection errors and inadequate programming are the most

common errors found during the controller operation. A final review

may avoid loss of time and damages.

The controller displays some messages to help the user identify

problems.

MESSAGE

PROBLEM

----

----

----

----

Open input. Without sensor or signal.

Err1

Err1

Err1

Err1

Err6

Err6

Err6

Err6

Configuration or connection problem in the Pt100

cable

Other error messages displayed by the controller can account for errors

in the input connections or type of selected input non compliant with the

sensor or signal applied to the input. If errors persist, even after a

review, contact the manufacturer. Inform also the device serial number.

To find out the serial number, press

for more than 3 seconds.

The controller also has a visual alarm (the display flashes) when the

PV value is out of the range set by spxl

spxl

spxl

spxl and spll

spll

spll

spll.

CALIBRATION

INPUT CALIBRATION

All inputs are factory calibrated and recalibration should only be done

by qualified personnel. If you are not familiar with these procedures

do not attempt to calibrate this instrument. The calibration steps are:

a) Select the input type to be calibrated.

b) Set the desired upper and lower display limits.

c) At the input terminals inject an electrical signal corresponding to a

known indication value a little higher than the lower display limit.

d) Select theinL(

inL(

inL(

inL( prompt. Through the

and

keys adjust PV

so that it matches the injected signal.

e) Inject a signal that corresponds to a value a little lower than the

upper limit of the display.

f) Select theink(

ink(

ink(

ink( prompt. Through the

and

keys adjust PV

so that it matches the injected signal.

g) Repeat steps c) to f) to improve calibration.

ANALOG OUTPUT CALIBRATION

1) Select type 11 or 12 at the I/O5 prompt.

2) Connect a current meter at the analog output.

3) Disable the auto-tune and soft-start functions.

4) Set the output low limit ovLL

ovLL

ovLL

ovLL to 0.0 % and the output high limit

ovkL

ovkL

ovkL

ovkL to 100.0 %.

5) Select the manual mode at the avto

avto

avto

avto prompt.

6) Enable the output at the rvn

rvn

rvn

rvn prompt.

7) At the operation cycle, set the MV to 0.0 %.

8) At the output low calibration ovLC

ovLC

ovLC

ovLC prompt, press the

and

key until the mA meter reads zero mA. Approach this value from

above.

9) Set 100.0 % for the manipulated variable (MV).

10) At the output high calibration ovkC

ovkC

ovkC

ovkC prompt, press the

and

key until the mA meter reads 20 mA. Approach this value

from below.

11) Repeat steps 7) to 10) as necessary.