Type, Dppo, Vn vni i i it t t t – NOVUS Controller N1100 User Manual

Page 6: Offs, Spll, Spxl, Rsll, Rsxl, Bavd, Addr

Controller N1100

NOVUS AUTOMATION

6/8

CONFIGURATION CYCLE

type

type

type

type

INPUT TYPE: Selects the input signal type to be connected

to the process variable input. Refer to Table 1.

This is the first parameter to be set.

dppo

dppo

dppo

dppo

DECIMAL POINT POSITION: For input types 16, 17, 18 or

19 only. Selects the decimal point position to be viewed in

both PV and SV.

vn

vn

vn

vnI

I

I

It

t

t

t

TEMPERATURE INDICATION IN ºC OR ºF: Selects the

display indication to be in ºC or ºF. Only available if input

type is other than 16, 17, 18 or 19.

offs

offs

offs

offs

SENSOR OFFSET: Offset value to be added to the PV to

compensate sensor error. Default value: zero.

spll

spll

spll

spll

SET POINT LOW LIMIT:

- Linear inputs: Sets the lower range for SV and PV

indication.

- T/C and Pt100 inputs: sets the lower range for SV.

spxl

spxl

spxl

spxl

SET POINT HIGH LIMIT:

- Linear inputs: Sets the upper range for SV and PV

indication.

- T/C and Pt100 inputs: sets the upper range for SV.

rsll

rsll

rsll

rsll

REMOTE SET POINT LOW LIMIT: Selects the lower range

for indication of the Remote Setpoint.

rsxl

rsxl

rsxl

rsxl

REMOTE SET POINT HIGH LIMIT: Selects the upper

range for indication of the Remote Setpoint.

bavd

bavd

bavd

bavd

DIGITAL COMMUNICATON BAUD RATE SELECTION:

0: 1200 bps; 1: 2400 bps; 2: 4800 bps; 3: 9600 bps; 4:

19200 bps.

addr

addr

addr

addr

SLAVE ADDRESS SELECTION: Identifies a slave in the

network. The possible address numbers are from 1 to 247.

I/O CYCLE (INPUTS AND OUTPUTS)

I

I

I

Io 1

o 1

o 1

o 1

I/O 1 FUNCTION: Selects the I/O function to be used at I/O

1 (relay 1). Options 0 to 5 are possible for this output. It is

normally used as option 5, PWM main control output. Refer

to Table 2 for functions.

I

I

I

Io 2

o 2

o 2

o 2

I/O 2 FUNCTION: Selects the I/O function to be used at I/O

2 (relay 2). Options 0 to 5 are available. This output is

normally used as alarm output. See Table 2 for functions.

I

I

I

Io 3

o 3

o 3

o 3

I/O 3 FUNCTION: Selects the I/O function to be used at I/O

3 (option 1). I/O 3 can be a relay output or a digital

input/output. Functions 0 to 10 are available. Refer to

Table 2 for functions. The presence of this I/O option is

detected by the controller and the prompt menu will only be

shown if the expansion option is available.

I

I

I

Io 4

o 4

o 4

o 4

I/O 4 FUNCTION: Selects the I/O function to be used at I/O

4 (option 2). I/O 4 can be a digital input/output. Functions 0

to 10 are available. Refer to Table 2 for functions. The

prompt menu will only be shown if the expansion option is

present.

I

I

I

Io 5

o 5

o 5

o 5

I/O 5 FUNCTION: Selects the I/O function to be used at I/O

5 (Analog Output). Functions 0 to 15 are available (See

Table 2). This option is normally used for main control

output or PV analog retransmission.

CALIBRATION CYCLE

All input and output types are factory calibrated. This cycle should

only be accessed by experienced personnel. If in doubt do not press

the

or

keys in this cycle.

Inl(

Inl(

Inl(

Inl(

INPUT LOW CALIBRATION: Sets the Process Variable low

calibration (offset). Several keystrokes at

or

might

be necessary to increment one digit.

Inx(

Inx(

Inx(

Inx(

INPUT HIGH CALIBRATION: Sets the Process Variable

span calibration (gain).

ovll

ovll

ovll

ovll

OUTPUT LOW CALIBRATION: Sets the analog current

output low calibration (offset).

Ovx(

Ovx(

Ovx(

Ovx(

OUTPUT HIGH CALIBRATION: Sets the analog current

output span calibration (gain).

(j l

(j l

(j l

(j l

COLD JUNCTION OFFSET CALIBRATION: Sets the cold

junction offset calibration.

xtyp

xtyp

xtyp

xtyp

HARDWARE TYPE: Configures the controller to recognize

the actual installed optional hardware (accessories). The

parameters menu will show the parameters relative to the

optional hardware:

0

0

0

0 - no optionals or c/ RS485 only;

1

1

1

1 - relay 3 (I/O 3);

2

2

2

2 - Digital I/O (2 inputs/outputs: I/O3 and I/O4);

3

3

3

3 - Heater break protection (option);

Rsl(

Rsl(

Rsl(

Rsl(

REMOTE SET POINT LOW CALIBRATION: Sets the

Remote Set Point low calibration (offset). Several

keystrokes at

or

might be necessary to increment

one digit.

Rsx(

Rsx(

Rsx(

Rsx(

REMOTE SET POINT HIGH CALIBRATION: Sets the

Remote Set Point span calibration (gain).

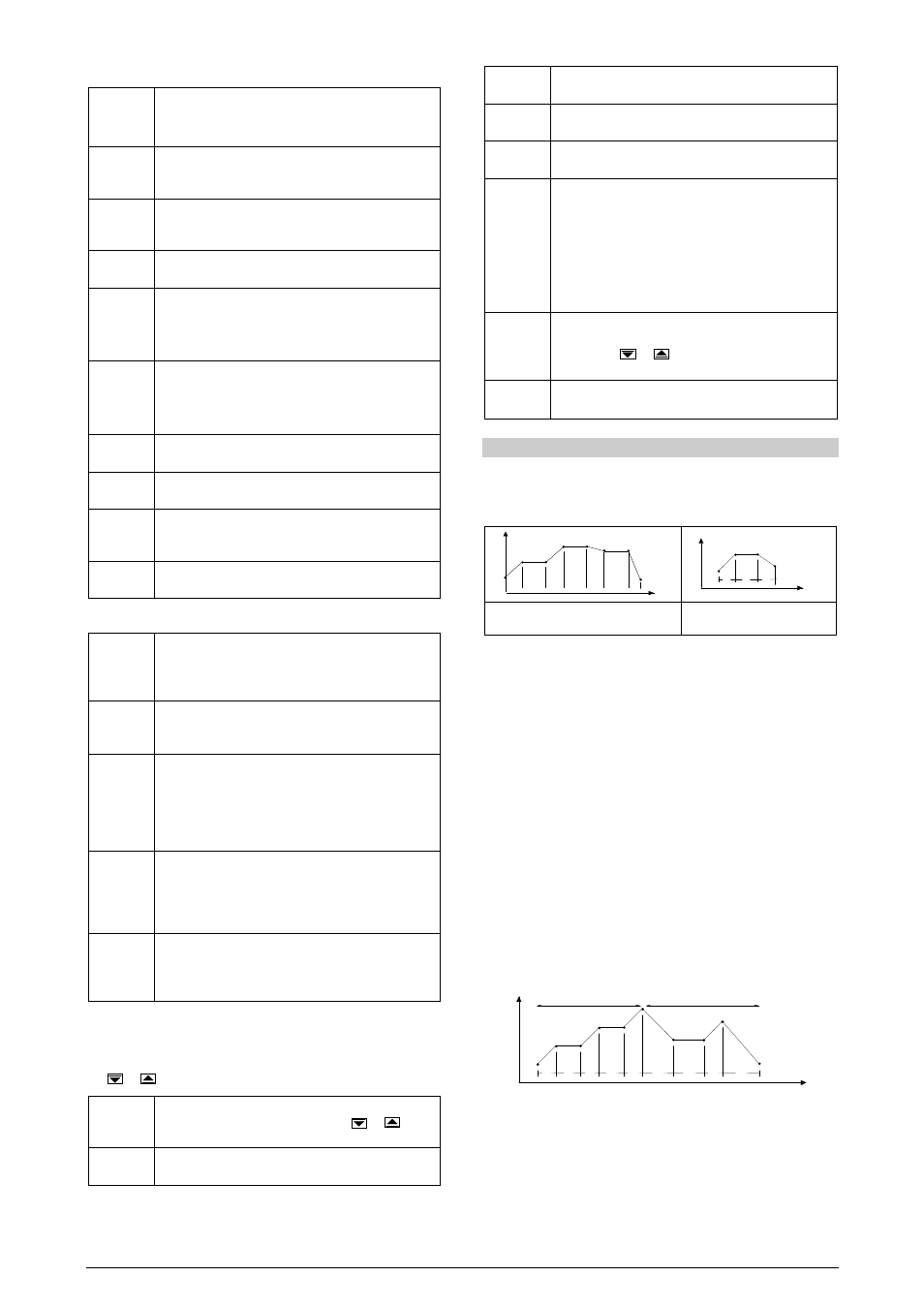

RAMP AND SOAK PROFILE PROGRAM

Seven ramp and soak profiles with up to 7 segments each can be

programmed. Longer profiles of up to 49 segments can be created by

linking 2 or more profiles.

SP

tim e

T 1

T2

T3

T4

T5

SP0

SP1

SP2

S P3

SP 4

SP5

SP6

SP7

T6

T 7

SV

time

T1

T2

T3

SP0

SP1

SP2

SP3

T4=0

Figure 11 - Example of a complete ramp and

soak profile

Figure 12 - Example of a profile with

fewer segments. (T4 is set 0)

To execute a profile with fewer segments just program 0 (zero) for the

time intervals that follow the last segment to be executed.

The program tolerance “Ptol

Ptol

Ptol

Ptol” defines the maximum deviation

between PV and SV for the execution of the profile. If this deviation is

exceeded, the program will be interrupted until the deviation falls to

within the tolerance band.

Programming 0 (zero) at this prompt disables the tolerance and the

profile execution will not to be halted even if PV does not follow SV

(time priority as opposed to SV priority).

LINK OF PROGRAMS

It is possible to create a more complex program, with up to 49

segments, joining the seven programs. This way, at the end of a

program execution the controller immediately starts to run another one.

When a program is created, it must be defined in the “LP

LP

LP

LP" screen

whether there will be or not another program.

To make the controller run a given program or many programs

continuously, it is only necessary to link a program to itself or the last

program to the first.

SV

time

T1

T2

T3

T4

T5

T1

T2

T3

T4

SP0

SP1

SP2

SP3

SP4

SP5 / SP0

SP1 SP2

SP3

SP4

Program 1

Program 2

Figure 13 - Example of two linked programs