NOVUS RHT-Air User Manual

Page 6

RHT-Air

NOVUS AUTOMATION

6/8

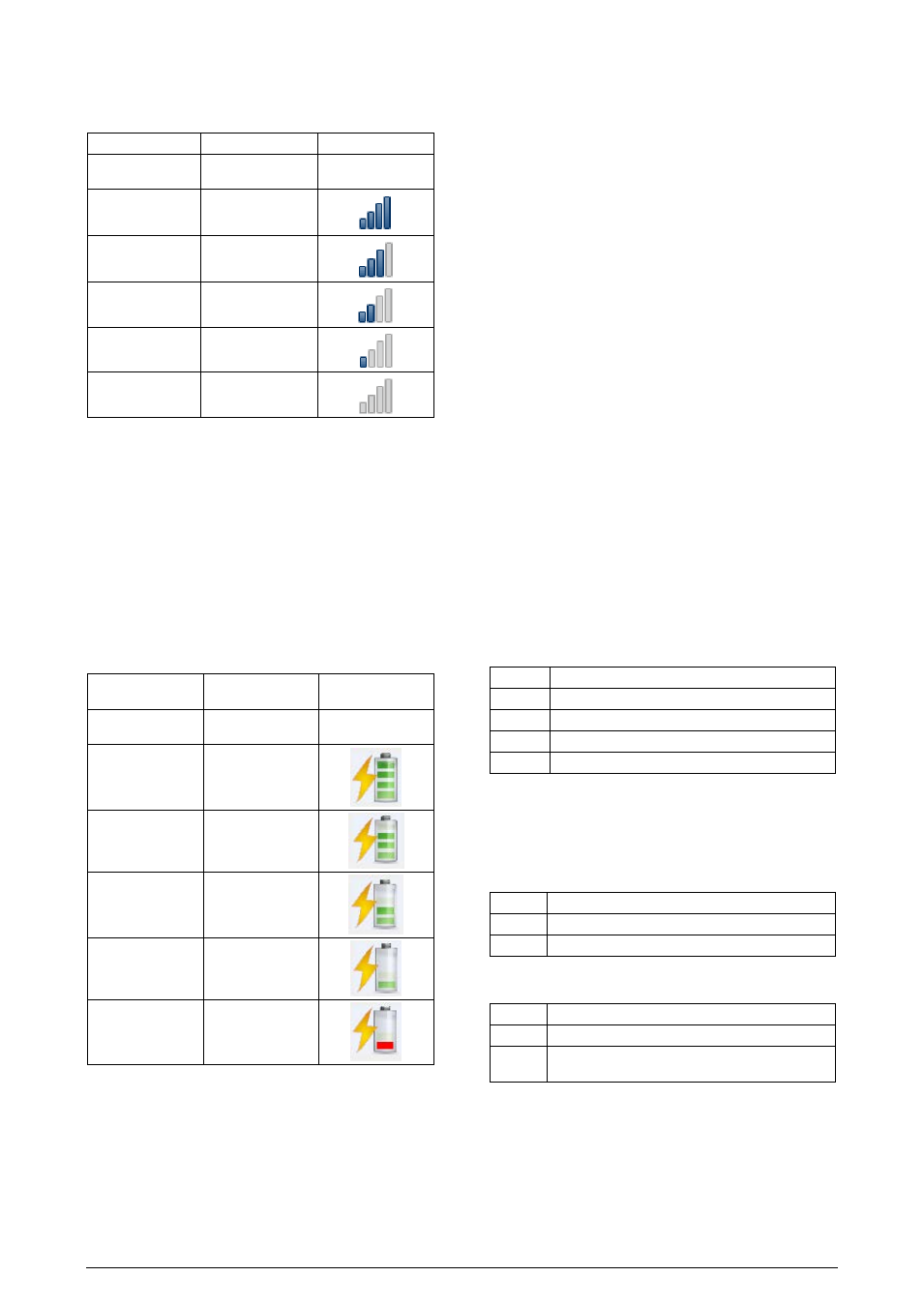

The table below relates the values obtained in the reading of the LQI to the

evaluation of the quality of the signal. The same information can be viewed in a

more intuitive way in the tab DigiConfig Software Diagnosis.

REGISTER VALUE

QUALITY

ICON

0

USB-connected

device

-15 to -60

Great

-60 to -70

Very Good

-70 to -80

Good

-80 to -90

Regular

-90 to -100

Bad

NOTE: The model described in the graphic takes in consideration the

propagation channel only. LQI may vary due to several factors, such as due

to peripheral obstacles such as trees, buildings, hills that interfere in the

propagation channels as explained by the Fresnel Zone phenomenon.

REGISTER 29 – BATTERY POWER

It has the value of the measurement of the battery power’s level in an

engineering unit. The decimal point is fixed in three places, the value has no

point and must be provided in the reading software.

A fully charged battery typically has a power above 3.6 V. As you use the

RHT-Air, the power of the battery will gradually decrease. It is

recommended that you check the value of this register regularly so that

when it reaches below 3.3 V, the battery can be replaced.

The verification of the capacity of the battery can be done through the

DigiConfig Software Diagnosis tab, which will display an icon. The evaluation

of battery capacity can be done according to the criteria presented below:

REGISTER VALUE

BATTERY

CAPACITY

ICON

0

USB-connected

device

3500 to 3700

Great

3400 to 3500

Very Good

3300 to 3400

Good

3200 to 3300

Average – Get ready

to replace your

battery

Lower than 3200

Bad – Replace the

battery as soon as

possible

NOTE 1: Even when the power is below 1100, the equipment will operate

normally.

NOTE 2: The gradual failure of the battery’s power is not linear, therefore,

though the equipment is able to continue working under tensions below 3.0V,

when it reaches this level, there is little left for its life, since the power will fail

more quickly.

NOTE 3: When the equipment is being supplied by an external power source,

the value presented represents the power supply of the circuit after the power

regulator reaches 3.6 V. This value may vary according to the setting’s

conditions, but should not be lower than 3.3V.

NOTE 4: The machine’s operating temperature has a significant impact on

the battery’s capacity. Temperatures below 0 °C will typically shorten the

battery’s life.

NOTE 5: The update time, as well as the operating power, have a significant

impact on the battery’s capacity. If the equipment is configured for the lowest

update interval, the battery will typically last less. The same happens when

the equipment is far from the AirGate-Modbus with which it should be

matched, needing a higher transmission power to operate.

REGISTER 30 – LAST POLL’S DURATION

Every time the RHT-Air publishes something on AirGate-Modbus, this

register gets a zero value. Every 100 ms, this register is increased in one

unit in order to indicate how long it has been since the last publication.

REGISTER 31 – MODBUS

It sets the address of the equipment on the Modbus network. This address

identifies the equipment on the Modbus network. Its configuration may range

from 1 and 247, and it should be stressed that there cannot be more than

one piece of equipment with the same address on the same network. RHT-

Air is originally manufactured with the address 246. When connected to a

USB interface, it always responds to Modbus functions through the address

246 to a BaudRate 115200 that has no parity and with 2 Stop Bits. When it is

in operation, it always responds through the address it was configured for in

this register according to the communication parameters of the Modbus

network on which it was installed.

REGISTER 32 – UPDATE TIME

It sets the configuration for how often the equipment wakes to publish

information on the AirGate-Modbus with which it is matched and update the

IHM screen.

The shorter the update time, the more recent the data available to the

master of the Modbus network will be, but the higher the energy

consumption spent and the battery's life will be proportionately shorter. On

the other hand, the higher the update time set, the lower the energy

consumption spent will be, thus providing a longer life for the battery.

REGISTER 33 – INDICATION MODE

It sets the mode of indication of the values read on the display. The

equipment is originally manufactured with the indication of temperature and

relative humidity.

CODE

DESCRIPTION

0

Indicates the temperature and relative humidity.

1

Indicates the temperature and dew point.

2

Indicates relative humidity and dew point.

3

Indicates the temperature only.

It has the value of the measurement in an engineering unit. The decimal

point is fixed in one place, the value has no point and must be expected for

the reading software.

REGISTER 34 – CONFIGURATION OF THE MEASUREMENT UNIT

It sets the measurement unit for both temperature and dew point. The

equipment is originally configured in (ºC).

CODE

UNIT

0

ºC

1

ºF

REGISTER 35 – DISABLES CONFIGURATION THROUGH A BUTTON

It sets the alteration of configuration through a button.

CODE

DESCRIPTION

0

Original standard value.

1

Disables the alteration of configuration of communication

parameters through a button.

REGISTER 36 – USER OFFSET DE FOR TEMPERATURE

It sets the user’s offset value in engineering units for temperature. The

equipment’s offset value is originally zero.

REGISTER 37 – USER OFFSET DE FOR HUMIDITY

It sets the user’s offset value in engineering units for relative humidity. The

equipment’s offset value is originally zero.

REGISTER 38 – ERROR VALUE

It contains the error value that is transmitted when the sensor has a problem.

The equipment's original value is -9999.