Protection of configuration, Operation level, Tuning level – NOVUS Controller N480D User Manual

Page 2

N480D Controller

NOVUS AUTOMATION

2/6

process (desired temperature for the process) on the green display

(bottom). During operation, the controller continues showing this

screen. In order to access other screens of this cycle, just press

.

All other Cycles are accessed when changes are required to the

controller’s configuration. In order to access these cycles just hold

down the

key for approximately three seconds. After this time, the

controller displays the first parameter of the next cycle (Tuning Cycle).

Holding the key down for three seconds, the next cycle (Input Cycle) is

also accessed.

Release the

key in the desired cycle. Press the

key again to

access all other parameters of this cycle. The

key allows to return

parameters within the cycle.

The upper display shows the parameter and the lower display shows

the value of this parameter. The

and

keys allow the operator

to change the value of the shown parameter.

After accessing the last parameter of the cycle, the controller returns to

the Operation cycle, indicating the temperature process and SP. With

the keyboard inactive for more than 20 seconds, the controller also

returns to the Operation cycle.

The value of the changed parameter is saved to permanent memory

and used by the controller when going to the next parameter, or if no

key is pressed within 20 seconds.

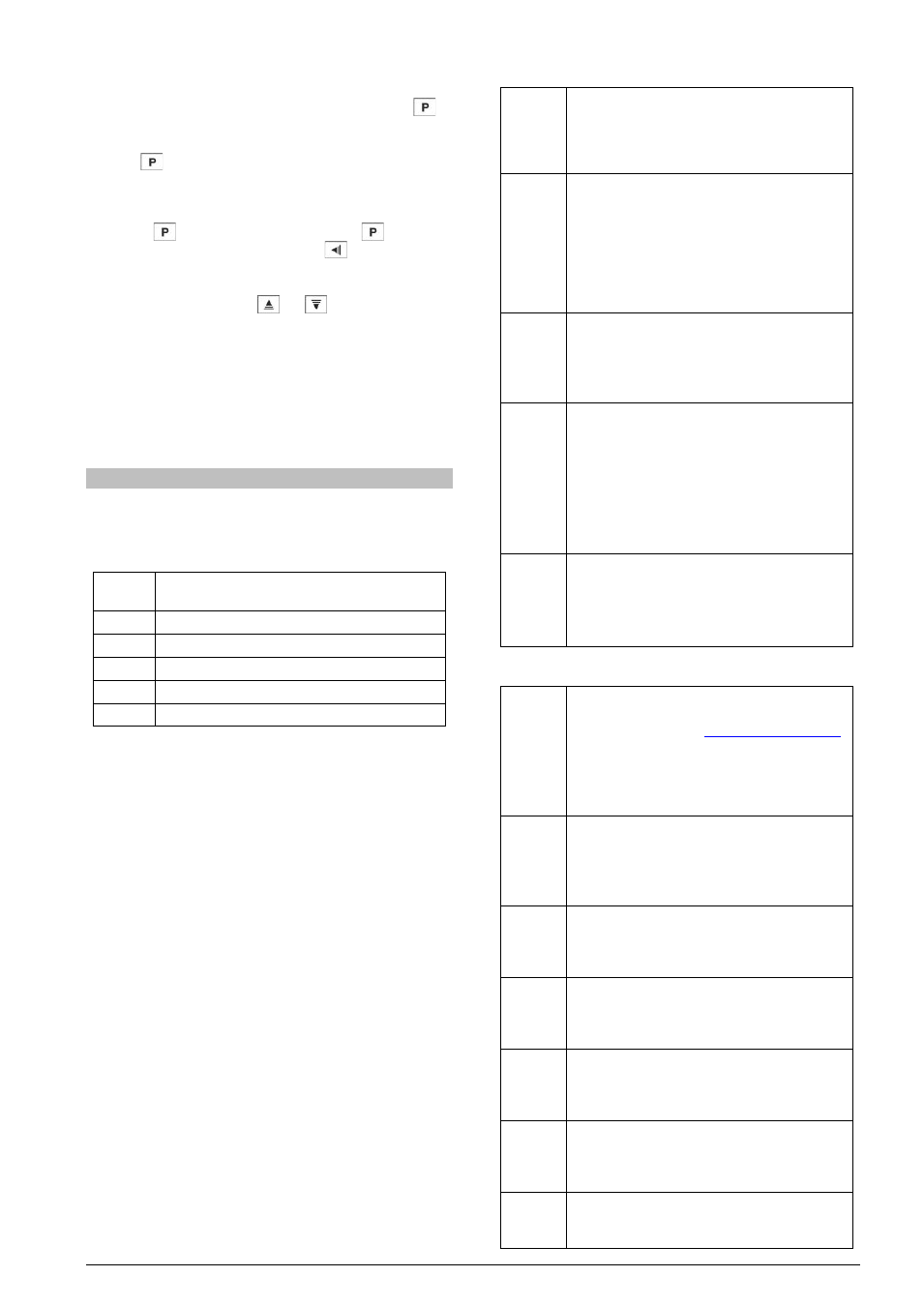

PROTECTION OF CONFIGURATION

The controller allows to protect the configuration elaborated by the

user, avoiding unauthorized changes. The parameter Protection

(PROt), in the Calibration level, determines the protection strategy,

limiting the access to particular levels, as shown by the table below.

Protection

Level

Protected Cycles

1

Only the Calibration level is protected.

2

Input and Calibration level.

3

Program, Input and Calibration level.

4

Tuning, Program, Input and Calibration level.

5

All levels are protected.

Table 2 – Levels of Protection for the Configuration

Access Password

The protected levels, when accessed, request the user to provide the

Access Password for granting permission to change the configuration

of the parameters on these levels.

The prompt PASS precedes the parameters on the protected levels.

If no password is entered, the parameters of the protected levels can

only be visualized.

The Access Password is defined by the user in the parameter

Password Change (PAS.(), present in the Calibration level.

The new controllers leave the factory with the access password defined

as 1111.

Protection of the access password

The controller provides a security system that helps prevent input of

numerous passwords trying to get the correct password. When 5 invalid

passwords in a row are identified, the controller stops accepting

passwords for 10 minutes.

Master Password

The Master Password is intended for allowing the user to define a new

password in the event of it being forgotten. The Master Password

doesn’t grant access to all parameters, only to the Password Change

parameter (PAS(). After defining the new password, the protected

parameters may be accessed (and modified) using this new password.

The master password is made up by the last three digits of the serial

number of the controller added to the number 9000.

As an example, for the equipment with serial number 07154321, the

master password is 9 3 2 1.

OPERATION LEVEL

TEMPERATURE

INDICATION

Control Set

Point

Temperature indication (PV) and control set

point - When turned on, the controller indicates the

process temperature on the upper display. The lower

display shows the SP value, which is the desired

temperature for the process.

rate

Rate

Temperature increase rate. It allows the user to

define the increase or decrease characteristic of the

process temperature, the current value to the value

programmed in SP. The rate is defined in Degrees

per minute. It is adjustable from 0.0 to 100.0 °C per

minute.

It is available when the Rate option is selected in the

Pr.ty parameter of the Input cycle.

lT SP

Level Time: Time interval in minutes, that the

process must remain in the temperature defined in

SP. Adjustable from 0 to 9999.

It is available when the Rate option is selected in the

Pr.ty parameter of the Input cycle.

E pr

Enable

Program

Program Execution – It determines the level and

ramp program execution.

Yes Executes program

No

Does not execute program

With enabled outputs (RvN= YES), the selected

program immediately enters in execution.

It is available when the Pr option is selected in the

Pr.ty parameter of the Input cycle.

Rvn

Run

Screen that enables or disables action of the

controller over the process. It acts as a switch,

turning the controller on or off.

YES

Outputs enables.

NO

Outputs not enabled.

TUNING LEVEL

Atvn

Auto tune

AUTO-TUNE: It enables automatic tuning of the PID

parameters (pb

,ir, dt). See chapter Determine PID

Parameters herein and at

for more details.

Off

Automatic tuning off

Fast

Execute tuning in fast mode

full

Execute tuning in fine mode

Pb

Proportional

band

PROPORTIONAL BAND: Value of the term P of

the control mode PID. In percentage of the

maximum span of the input type.

When set to zero (0), control action is ON/OFF.

Adjust of between 0 and 500.0 %.

Ir

Integral rate

INTEGRAL RATE: Value of the term I of the control

mode PID, in repetitions per minute. This constant

is not used when controller is set to ON/OFF action

(Pb=0). Adjustable between 0.00 and 55.20.

Dt

derivative time

DERIVATIVE TIME: Value of the term D of the

control mode PID, in seconds. This constant is not

used when controller is set to ON/OFF action

(Pb=0). Ajustable between 0 and 250.

(t

Cycle time

CYCLE TIME: Pulse Width Modulation (PWM)

period in seconds. This constant is not used when

controller is set to ON/OFF action (Pb=0).

Adjustable between 0.5 and 99.99

KySt

HYSterisis

CONTROL HYSTERESIS: Is the hysteresis for

ON/OFF control (set in temperature units). This

parameter is only used when the controller is in

ON/OFF mode (Pb=0).

A1SP

A2SP

Alarm SP

SETPOINT for Alarm 1 and 2: Tripping point for

alarm 1 and 2.