Protection of configuration, Configuration parameters, Operation cycle – NOVUS Controller N2000 User Manual

Page 6: Auto tuning cycle, Avto, Pr n, P.seg, T.seg, Atvn

Controller N2000

NOVUS AUTOMATION

6/11

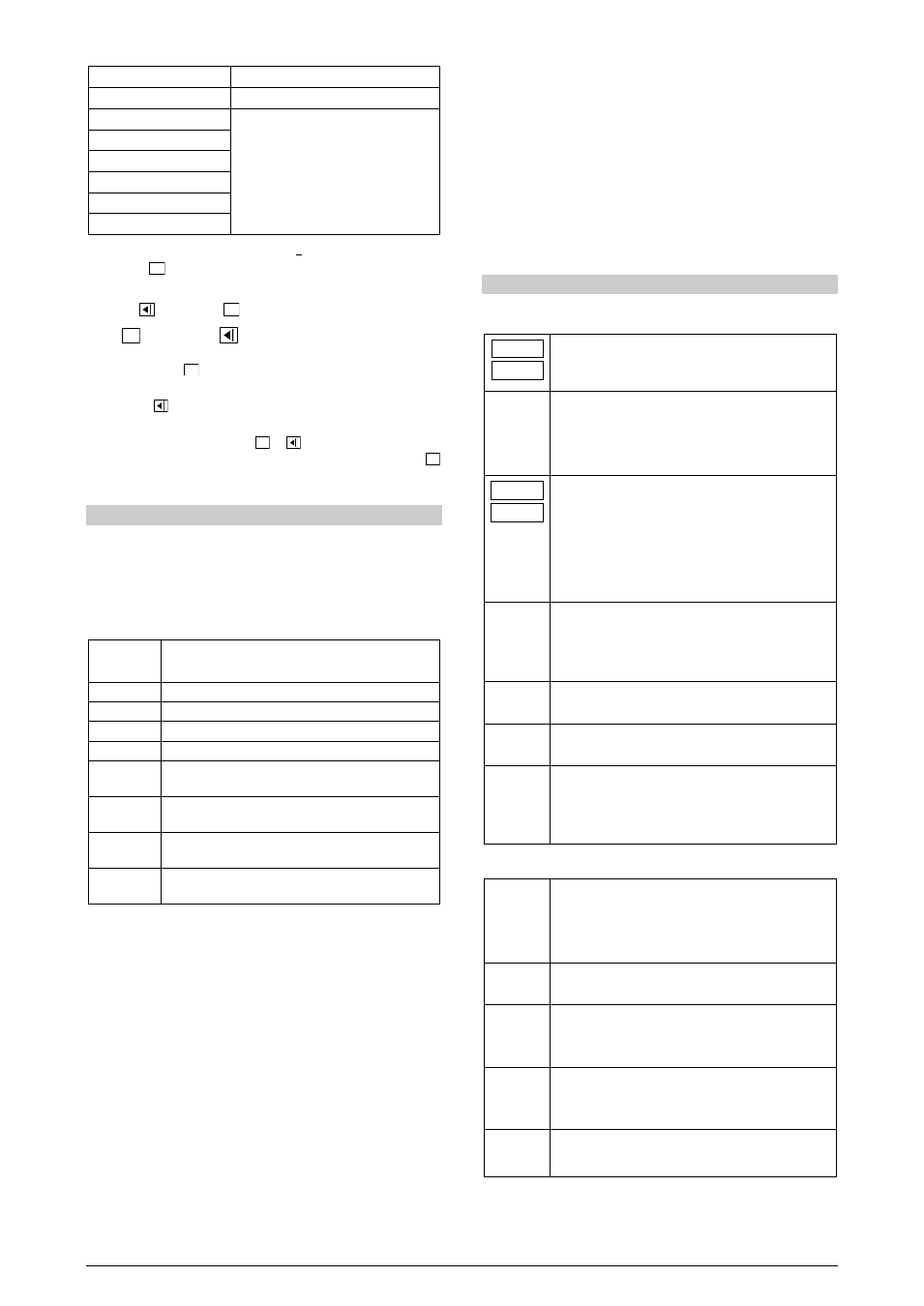

CYCLE

ACCESS

1- Operation

Free access parameters

2- Tuning

Reserved access parameters

3- R&S Program

4- Alarms

5- Input Configuration

6- I/Os

7- Calibration

The parameters in the operation level (1

st

level) are easily accessed

through the

P

key. The access deeper levels use the combination of

Keys:

(BACK) and

P

(PROG) pressed simultaneously

Press

P

to advance or

to retrocede parameters within a level.

At the end of each level, the controller returns to the operation level.

Keep pressing the

P

key to move fast forward in the level.

Alternatively, the controller returns to the operation level after

pressing the

key for 3 seconds.

All configuration parameters are stored in protected memory. The

values are saved when the keys

P

or

are pressed after changing

a parameter value. The value of SP is saved upon pressing the

P

key or every 25 seconds.

PROTECTION OF CONFIGURATION

The controller provides means for protecting the parameters

configurations, not allowing modifications to the parameters values,

avoiding tampering or improper manipulation.

The parameter Protection (PROt), in the Calibration level,

determines the protection strategy, limiting the access to particular

levels, as shown by the table below.

Protection

level

Protected cycles

1

Only the Calibration level is protected.

2

I/Os and Calibration levels.

3

Tuning, I/Os and Calibration levels.

4

Alarm, Tuning, I/Os and Calibration levels.

5

Programs, Alarm, Tuning, I/Os and Calibration

levels.

6

Tuning, Programs, Alarm, Input, I/Os and

Calibration levels.

7

Operation (except SP), Tuning, Programs, Alarm,

input, I/Os and Calibration levels.

8

Operation, Tuning, Programs, Alarm, Input, I/Os

and Calibration levels.

Table 7 – Levels of Protection for the Configuration

Access Password:

The protected levels, when accessed, request the user to provide the

Access Password for granting permission to change the

configuration of the parameters on these cycles.

The prompt PASS precedes the parameters on the protected levels.

If no password is entered, the parameters of the protected cycles can

only be visualized.

The Access Code is defined by the user in the parameter Password

Change (PAS.(), present in the Calibration level. The factory default

for the password code is 1111.

Protection of the access code

The protection system built into the controller blocks for 10 minutes

the access to protected parameters after 5 consecutive frustrated

attempts of guessing the correct password.

Master Password

The Master Password is intended for allowing the user to define a

new password in the event of it being forgotten. The Master

Password doesn’t grant access to all parameters, only to the

Password Change parameter (PAS(). After defining the new

password, the protected parameters may be accessed (and modified)

using this new password.

The master password is made up by the last three digits of the serial

number of the controller added to the number 9000.

As an example, for the equipment with serial number 07154321, the

master password is 9 3 2 1.

CONFIGURATION PARAMETERS

OPERATION CYCLE

PV Indication

(Red)

SV Indication

(Green)

PV / SP indication- The upper display shows the

current value of PV. The lower display shows the

control SP value.

Avto

Control

Control Mode:

Yes

-Means automatic control mode.

no -Means manual control mode.

Bumpless transfer between automatic and manual.

PV Indication

(Red)

MV Indication

(Green)

Screen PV and MV: The upper display shows PV

value and the lower display shows the percentage of

MV applied to the control output. When in manual

control the MV value can be manually changed. When

in auto mode the MV value can only be viewed.

To distinguish the MV display from the SV display,

the MV is shown flashing intermittently.

Pr n

Program

number

Execution of Program - Selects the ramp and soak

profile program to be executed.

0 -does not execute program

1 a 7 -number of the program to be executed

p.seg

Indicative screen. Shows the current segments

number of the running program.

t.seg

Indicative screen. Shows the current segments

remaining time.

rvn

Control Enable:

YES -means that the control output and alarms

are enabled.

NO -means they are disabled.

AUTO TUNING CYCLE

atvn

Auto Tune: Habilita a sintonia automática dos

parâmetros PID.

YES

-Auto-tune enable

NO

-Do not execute auto tune

Pb

Proportional Band - Percentage of maximum input

span. Select zero for ON / OFF control.

ir

Integral Rate

‘

Value of the term I of the PID algorithm, in repetitions

per minute.

Displayed only if proportional band ≠ 0.

Dt

Derivative

Time

Derivative Time - Value of the term D of the control

mode PID, in seconds.

Displayed only if proportional band ≠ 0.

(t

Cycle Time

Pulse Width Modulation (PWM) period in seconds.

Displayed only if proportional band ≠ 0.