Digital output, Operation – NOVUS Controller N2000 User Manual

Page 5

Controller N2000

NOVUS AUTOMATION

5/11

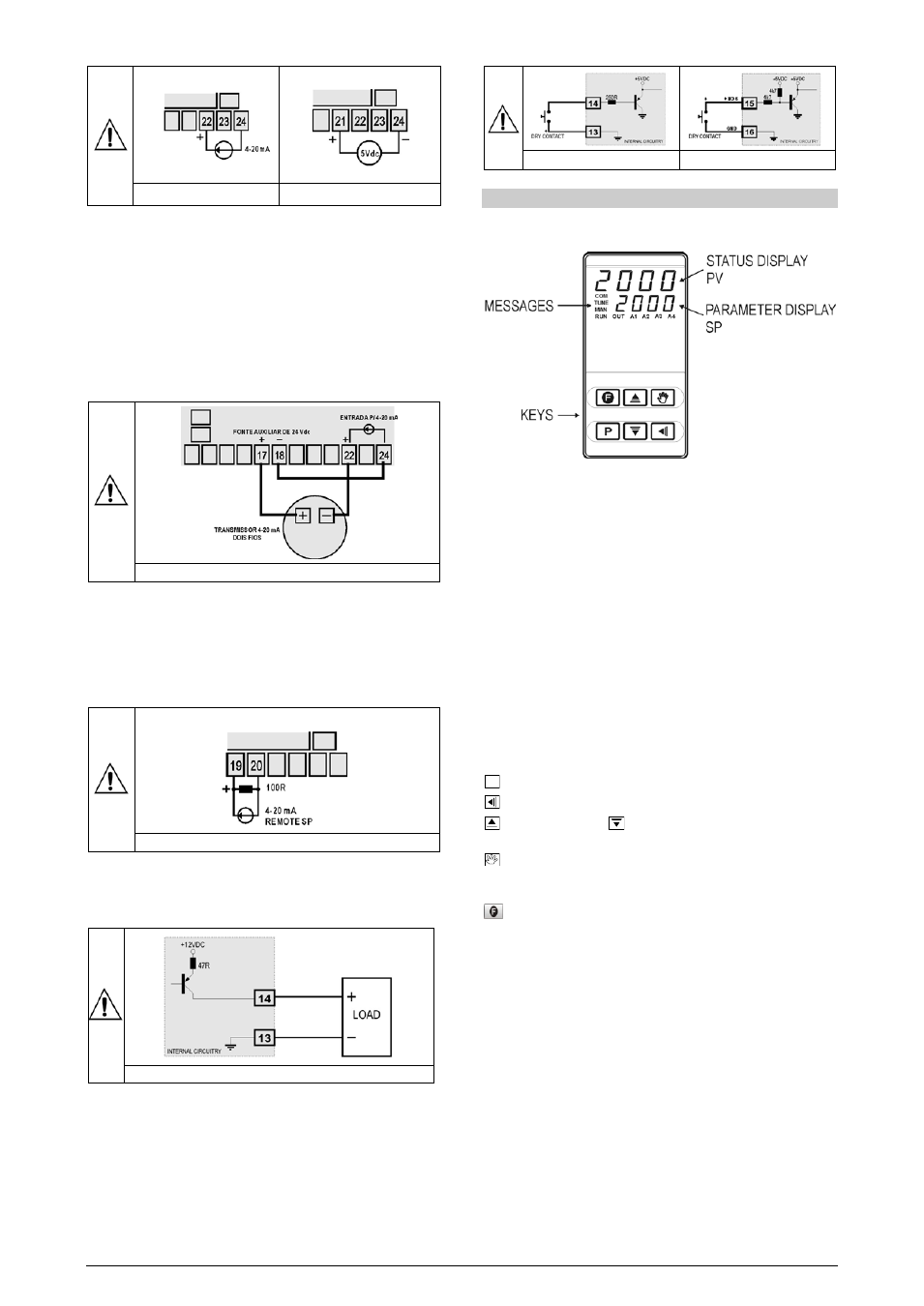

Fig. 4a – Connection of 4-20 mA

Fig. 4b – Connection of 5 Vdc

• 4-20 mA

Refer to Fig. 4a. (The controller provides an internal electronic shunt

for the input current. No changes in the circuit are necessary).

• 0-5 Vdc:

Refer to Figure 4b for connecting voltage signals.

• 4-20 mA:

The connections for current signals 4-20 mA must be carried-out

according to Figure 4c.

Fig. 4c -

4-20 mA transmitter using the N2000 24 Vdc supply

• Remote setpoint

The remote Setpoint (SP) is enabled by an external digital signal in

either I/O5 or I/O6, when programmed with the code rsp (Select

remote SP input).

An external resistor shunt of 100 Ω is required between the terminals

19 and 20.

Fig. 4d -

Connection for remote SP

(0-20 / 4-20 mA)

DIGITAL OUTPUT

I/O5 can also be configured as digital output. An example of usage is

shown in Fig. 5. I/O5 is electrically isolated from the sensor input.

Fig. 5 –

I/O5 with output pulse for SSR.

DIGITAL INPUT

I/O5 and I/O6 can be used as digital inputs, accepting either dry contact

or NPN open collector signals. Fig. 6 shows a switch driving the I/O5

digital input. The digital input at I/O6 is driven only by dry contact

signals. Fig. 7 shows a typical digital input wiring for I/O6.

Fig. 6 – Digital input at I/O5

Fig. 7 – Digital input at I/O6

OPERATION

The front panel is shown in Fig. 8.

Fig. 8 - Front panel parts

Status display/PV: shows the value of PV (Process Variable). When

in programming mode, shows the parameter name.

Parameter display/SV: shows the SV (Setpoint Variable) value and

the value of other parameters of the controller.

COM Indicator: Flashes when communication messages are sent by

the controller.

TUNE Indicator: Lights during the execution of PID automatic tunning.

MAN Indicator: Lights when the controller is in manual.

RUN Indicator: Lights when the controller is active, with control and

alarm outputs enabled.

OUT Indicator: For relay or pulse control output, reflects the actual

state of the output. If an analog output is assigned for control, lights

continuously.

A1, A2, A3 and A4 Indicators: Status of the alarms.

P

- PROG key: used to walk through the menu cycles

- BACK key: go back to the previous displayed parameter

- INCREASE and

- DECREASE keys: Used to change

parameter values

-AUTO/MAN KEY: Shortcut for automatic/manual control

selection. Alternates the control mode between automatic and

manual each time the key is pressed.

-PROGRAMMABLE FUNCTION KEY: Can be assigned to the

special functions described for the RVN , RSP, KPRG,

e PR1

according to Table 2.

When the controller is turned on, its firmware version is displayed for

3 seconds, after which the controller starts normal operation. The

values of PV and SV are displayed and the outputs are enabled.

Before the controller is ready to be used in a given process, it

requires some basic configuration, such as:

• Input type (T/C, Pt100, 4-20 mA).

• Control Setpoint Value (SP).

• Control Output Type (relays, 0-20 mA, 4-20 mA).

• PID parameters (or hysteresis for ON / OFF control)

Other functions, including alarms, ramp and soak, timer, digital input,

etc., may be useful for a better system performance. The parameters

are grouped in 7 cycles.