Customized linearization cycle, Hardware cycle (manual mode), Calibration cycle – NOVUS N1500FT Indicator User Manual

Page 7: Configuration protection, Master password, Maintenance, Problems with indicator

N1500FT Flow Indicator

NOVUS AUTOMATION

7/9

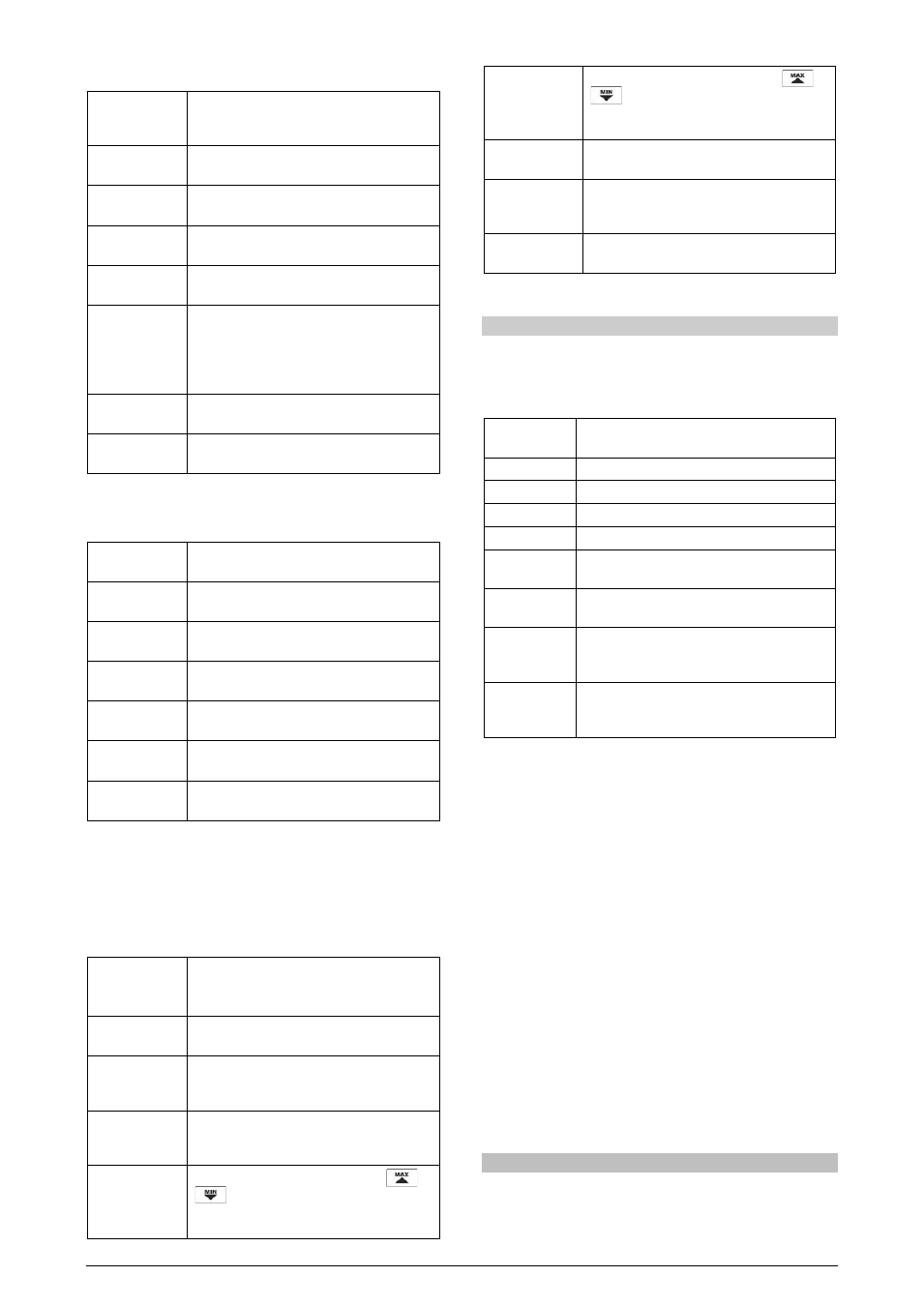

CUSTOMIZED LINEARIZATION CYCLE

Lin.enbl

Linearization

Enable

Enables linearization. Applicable only when

flow input is 4-20 mA.

1np.01

Input 01

First input point for linearization.

0vT.01

Output 01

First output point for linearization.

1np.02

Input 02

Second input point for linearization.

0vT.02

Output 02

Second output point for linearization.

…

27 input and output points for linearization.

1np.30

Input 30

Last input point for linearization.

0vT.30

Output 30

Last output point for linearization.

Table 11 – Customized linearization cycle keys

HARDWARE CYCLE (MANUAL MODE)

manual

Manual mode

Enables manual mode of operation.

(ur.0ut

Current Out

Current output status in manual mode.

PUl.0ut

Pulse Out

Pulse output status in manual mode.

Rl1.0ut

Relay 1 Out

Relay 1 output status in manual mode.

Rl2.0ut

Relay 2 Out

Relay 2 output status in manual mode.

Rl3.0ut

Relay 3 Out

Relay 3 output status in manual mode. Visible

only for the 4 relays model.

Rl4.0ut

Relay 4 Out

Relay 4 output status in manual mode. Visible

only for the 4 relays model.

Table 12 – Hardware cycle keys

CALIBRATION CYCLE

All input and output types are factory calibrated. If recalibration is

required, it must be performed by a specialist. If this cycle is

accidentally accessed, go through all parameters without changing

values.

PASS

Password

Access Password entry.

This parameter is shown before protected

cycles. See item Configuration Protection.

(alib

Calibration

Enables calibration.

inL(

Input Low

Calibration

Entry of value close to the beginning of scale

in 4-20 mA input, within scale specified in

InLL

and InKL.

inx(

Input High

Calibration

Entry of value close to the end of scale in 4-20

mA input, within scale specified in InLL and

InKL

.

ovL(

Output Low

Calibration

On this screen, whenever you press

or

, a standard current close to 4 mA will

be applied. Measure current, in mA, and enter

it on this screen.

ovx(

Output High

Calibration

On this screen, whenever you press

or

, a standard current close to 20 mA will

be applied. Measure current, in mA, and enter

it on this screen.

rstr

Restore

Restores factory calibration.

Pa.(x

Password

Change

Changes user password.

Prot

Protection

Protection level.

Table 13 – Calibration cycle keys

CONFIGURATION PROTECTION

The indicator allows configuration protection as determined by user,

preventing unauthorized changes. The Protection (PROt) parameter,

in the Calibration cycle, determines the protection level to be

adopted, limiting Access to cycles, as shown in the table below.

PROTECTION

LEVEL

PROTECTED CYCLE

1

Calibration

2

Calibration + Hardware

3

Calibration + Hardware + Linearization

4

Calibration + Hardware + Linearization + Relays

5

Calibration + Hardware + Linearization + Relays

+ Output Config. + Input Config.

6

Calibration + Hardware + Linearization + Relays

+ Output Config. + Input Config. + Functions

7

Calibration + Hardware + Linearization + Relays

+ Output Config. + Input Config. + Functions +

Alarm

8

Calibration + Hardware + Linearization + Relays

+ Output Config. + Input Config. + Functions +

Alarm + Main

Table 14 – Configuration Protection Levels

Access Password

To access the protected cycles, it is necessary to enter an Access

Password that allows altering the configuration of parameters in

these cycles.

The access password is entered in the Pass parameter, which is

shown in the first of protected cycles.

Without a protection password, parameters of the protected cycles

can be only viewed.

The Access Password is defined by user in the Password Change

(PA.(k) parameter, shown in the Calibration cycle.

New indicators come from factory with access password “1111”.

MASTER PASSWORD

If you forget the access password, it is possible to use the Master

Password feature. When this password is entered, users gain access

to the Password Change (PA.(k) parameter and are allowed to

specify a new access password to the indicator.

The Master Password consists of the last three digits of the indicator

serial number added to the number 9000.

For example, for a device with serial number “12154321”, master

password is “9 3 2 1”.

MAINTENANCE

PROBLEMS WITH INDICATOR

Connection errors and inadequate programming are the main

problems when using the indicator. A final review should prevent

losses and wasting time.