Caution – American Electric Lighting AVL new User Manual

Page 2

American Electric Lighting a division of Acuity Lighting Group, Inc. Conyers, GA

DRAWING NO. A66193 REV A

(BACK)

©2004 ACUITY LIGHTING GROUP, INC.

PART NUMBER 057-71-66193

FACTORY INSTALLED OPTIONS

FACTORY INSTALLED OPTIONS

FACTORY INSTALLED OPTIONS

FACTORY INSTALLED OPTIONS

FACTORY INSTALLED OPTIONS

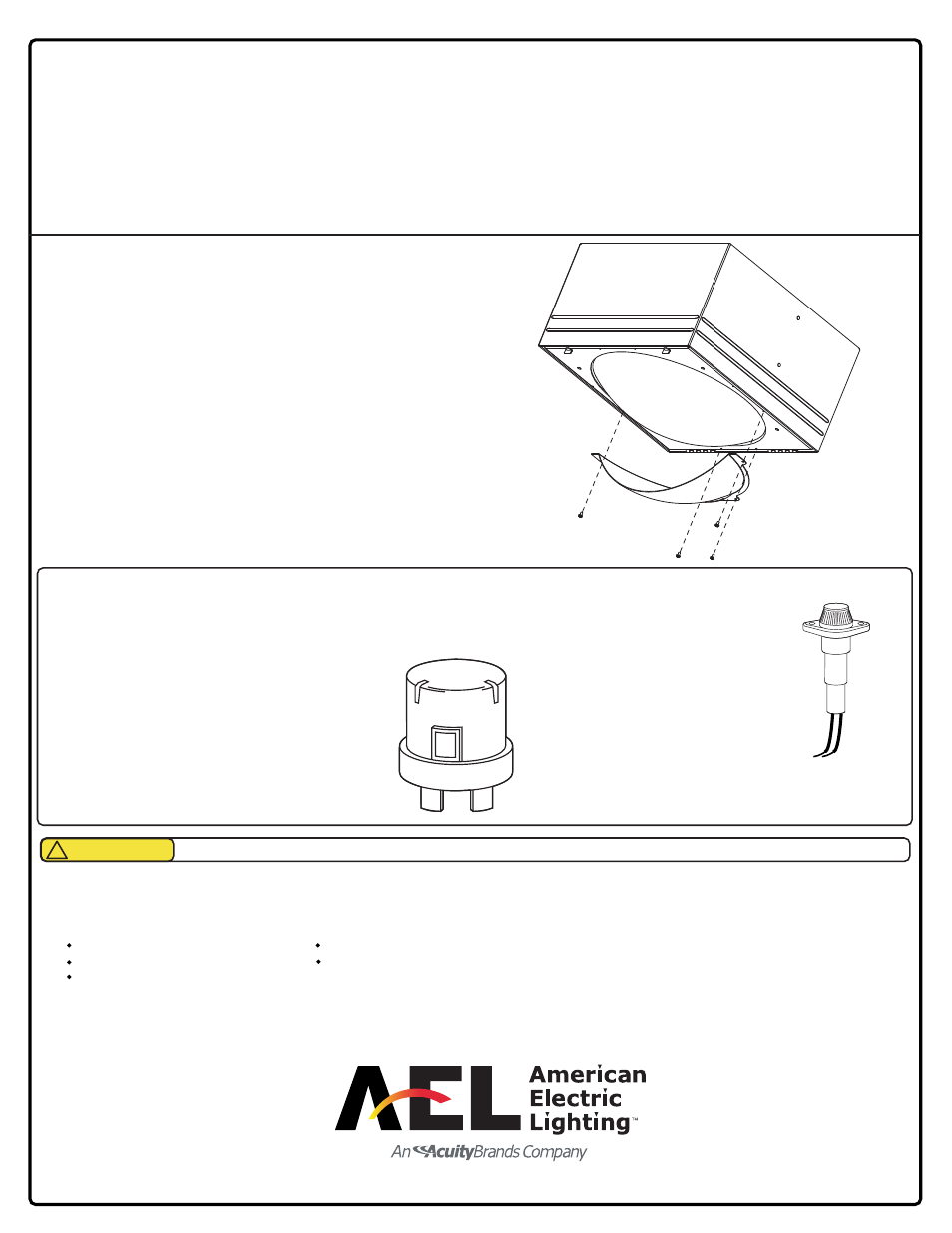

NEMA TWIST LOCK RECEPTACLES AND PHOTOCONTROL

NEMA TWIST LOCK RECEPTACLES AND PHOTOCONTROL

NEMA TWIST LOCK RECEPTACLES AND PHOTOCONTROL

NEMA TWIST LOCK RECEPTACLES AND PHOTOCONTROL

NEMA TWIST LOCK RECEPTACLES AND PHOTOCONTROL

Photocell receptacle: PR

Photocell receptacle: PR

Photocell receptacle: PR

Photocell receptacle: PR

Photocell receptacle: PR

The photocell receptacle is factory installed, and be ordered with

MUST

MUST

MUST

MUST

MUST

the fixture as it is wired to correspond with the voltage of the fixture.

Photocontrols

Photocontrols:

Photocontrols:

Photocontrols:

Photocontrols: The photocontrol is shipped separately

and must be field installed.

Important:

Important:

Important:

Important:

Important: The voltage of the photocontrol must

be the same as the fixture voltage.

SINGLE/DOUBLE FUSING - complete with fuses

SINGLE/DOUBLE FUSING - complete with fuses

SINGLE/DOUBLE FUSING - complete with fuses

SINGLE/DOUBLE FUSING - complete with fuses

SINGLE/DOUBLE FUSING - complete with fuses

S F

S F

S F

S F

S F - Single Fuse is internally accessible for use

with 120, 277, or 347 volt fixtures

DF

DF

DF

DF

DF - Double Fuse is internally accessible for use

with 208, 220, 240, or 480 volt fixtures.

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

TROUBLESHOOTING

If this fixture fails to operate properly, check to make sure:

The correct lamp is properly installed.

The fixture is grounded correctly.

The fixture is wired correctly.

The line voltage at the fixture is correct.

The lamp is not faulty.

If all these variables have been checked and the fixture still does not operate as specified, contact your local American Electric Lighting distributor or agent.

Observe lamp manufacturer’s recommendations and restrictions on lamp operations, particularly ballast type, burning position, etc.

MAINTENANCE:

MAINTENANCE:

MAINTENANCE:

MAINTENANCE:

MAINTENANCE: Your fixture is designed for years of trouble-free operation. For optimum performance, periodically clean reflector and lens with a soft, damp cloth.

IMPORTANT: DO NOT

DO NOT

DO NOT

DO NOT

DO NOT use abrasive materials, glass cleaner or other solvents on lens or paint. Use only mild, soapy water.

Glass Lens Change

Glass Lens Change

Glass Lens Change

Glass Lens Change

Glass Lens Change

Tools Needed: 1/2" wrench or socket

(For convenience, the lens is interchangable from a flat full cutoff lens to a contoured drop lens or drop lens to flat lens)

1. Open the doorframe assembly, loosen the (4) lens clips securing nuts using a 1/2" wrench or socketsand remove them from the studs being careful to keep the lens

from falling or being damaged.

2. Take the existing lens gasket and place on new lens, place lens in doorframe assembly and re-apply the (4) lens securing clips and their (4) nuts securing well.

(Do not secure to the point of bending the clips)

Note:

Note:

Note:

Note:

Note: The optical reflectors are SPECIFICALLY designed for their respective lens option. We can not accept responsibility for photometric performance when

The optical reflectors are SPECIFICALLY designed for their respective lens option. We can not accept responsibility for photometric performance when

The optical reflectors are SPECIFICALLY designed for their respective lens option. We can not accept responsibility for photometric performance when

The optical reflectors are SPECIFICALLY designed for their respective lens option. We can not accept responsibility for photometric performance when

The optical reflectors are SPECIFICALLY designed for their respective lens option. We can not accept responsibility for photometric performance when

these are not matched.

these are not matched.

these are not matched.

these are not matched.

these are not matched.

EHS (External Houseside Shield) Option

Tools Required: Drill, 5/32" drill bit, slotted screwdriver or 5/16" nut driver

The EHS is unique and aesthetically pleasing design that can be rotated to any

desired side needed to help eliminate unwanted spill light.

1.

1.

1.

1.

1. Choose the side needed to apply the shield. Align the shield in this position

Choose the side needed to apply the shield. Align the shield in this position

Choose the side needed to apply the shield. Align the shield in this position

Choose the side needed to apply the shield. Align the shield in this position

Choose the side needed to apply the shield. Align the shield in this position

and choose the four indicator dimples that need to be drilled out, mark or

and choose the four indicator dimples that need to be drilled out, mark or

and choose the four indicator dimples that need to be drilled out, mark or

and choose the four indicator dimples that need to be drilled out, mark or

and choose the four indicator dimples that need to be drilled out, mark or

remember

remember

remember

remember

remember which dimples will be drilled.

which dimples will be drilled.

which dimples will be drilled.

which dimples will be drilled.

which dimples will be drilled.

2.

2.

2.

2.

2. Setting shield aside, open doorframe in order to keep drill from penetrating

Setting shield aside, open doorframe in order to keep drill from penetrating

Setting shield aside, open doorframe in order to keep drill from penetrating

Setting shield aside, open doorframe in order to keep drill from penetrating

Setting shield aside, open doorframe in order to keep drill from penetrating

reflector. Drill the indicator dimples chosen with 5/32" drill bit, being careful not

reflector. Drill the indicator dimples chosen with 5/32" drill bit, being careful not

reflector. Drill the indicator dimples chosen with 5/32" drill bit, being careful not

reflector. Drill the indicator dimples chosen with 5/32" drill bit, being careful not

reflector. Drill the indicator dimples chosen with 5/32" drill bit, being careful not

to penetrate the lens gasket by keeping drill perpendicular to the doorframe.

to penetrate the lens gasket by keeping drill perpendicular to the doorframe.

to penetrate the lens gasket by keeping drill perpendicular to the doorframe.

to penetrate the lens gasket by keeping drill perpendicular to the doorframe.

to penetrate the lens gasket by keeping drill perpendicular to the doorframe.

3.

3.

3.

3.

3. Close the doorframe and secure it. Align shield with chosen drilled holes,

Close the doorframe and secure it. Align shield with chosen drilled holes,

Close the doorframe and secure it. Align shield with chosen drilled holes,

Close the doorframe and secure it. Align shield with chosen drilled holes,

Close the doorframe and secure it. Align shield with chosen drilled holes,

install the 4 screws provided with phillips type screwdrive.

install the 4 screws provided with phillips type screwdrive.

install the 4 screws provided with phillips type screwdrive.

install the 4 screws provided with phillips type screwdrive.

install the 4 screws provided with phillips type screwdrive.

CAUTION

!