Maintenance - beginning of season, Filter, Start-up – COOK HMD EN User Manual

Page 7: High limit, Burner, Snow accumulation, Motors, Wheels, Bearings

7

size. The instructions provided in this manual and those

provided by the bearing manufacturer will minimize any

bearing problems.

Lubricate bearings prior to periods of extended

shutdowns or storage and rotate shaft monthly to aid in

corrosion prevention. If the fan is stored more than three

months, purge the bearings with new grease prior to start-

up.

Motors are provided with a polyurea mineral oil NGLI #2

grease. All additions to the motor bearings are to be with

a compatible grease such as Exxon Mobil Polyrex EM and

Chevron SRI.

The above intervals should be reduced to half for vertical

shaft installations.

Relubrication Intervals

RPM

Temp °F

Greasing Interval

Up to 1000

-30 to 120

6 months

120 to 200

2 months

1000 to 3000

-30 to 120

3 months

120 to 200

1 month

Over 3000

-30 to 120

1 month

120 to 200

2 weeks

Any Speed

< -30

Consult Factory

Any Speed

> 200

1 week

Filter

Filter maintenance is generally limited to cleaning and

replacement.

If aluminum mesh filters are installed, they can be

washed in warm soapy water.

An adhesive spray can be added to aluminum mesh

filters to increase their efficiency.

If disposable filters are installed, they can be checked

by holding up to a light source. If light cannot pass through

the filter, it should be replaced.

When reinstalling filters, be sure to install them with the

airflow in the correct direction. An airflow direction arrow is

located on the side of the filters.

Replacement filters should be from the same

manufacturer and the same size as the original filters

provided with the unit.

Maintenance - Beginning of season

Start-Up

Repeat the Blower Start-Up Step #5 and Direct Gas

Start-Up Steps #1, #2 and #3. This will ensure that the gas

and air are set properly before the heating season begins

and should lead to trouble free operation all winter.

High Limit

The high limit switch may have tripped over the summer;

it should be checked and reset if necessary.

Burner

Inspect the burner for accumulation of scales on both the

upstream and downstream sides of the mixing plates. Any

scaling or foreign material should be removed with a wire

brush.

Visually check that all holes in the mixing plates are

clear. If any burner ports are plugged (even partially), clear

them with a piece of wire or another appropriate tool.

NOTICE! Premature or frequent belt failures can

be caused by improper belt tension, or misaligned

sheaves. Abnormally high belt tension or drive

misalignment will cause excessive bearing loads

and may result in failure of the fan and/or motor

bearings. Abnormally low belt tension will cause

squealing on start-up, excessive belt flutter,

slippage, and overheated sheaves.

1. V-belt drives must be checked on a regular basis for

wear, tension, alignment, and dirt accumulation.

2. Check the tension by measuring the deflection in the

belt as shown here.

3. Check the alignment by using a straight edge across

both sheaves. The drawings below show where to

measure the allowable gap for the drive alignment

tolerance. All contact points (indicated by WXYZ)

are to have a gap less than the tolerance shown in

the table. When the pulleys are not the same width,

the allowable gap must be adjusted by half of the

difference in width.

Snow Accumulation

Clear snow away from roof mounted units. Keep the

snow clear of the intake and access doors.

Motors

Motor maintenance is generally limited to cleaning and

lubrication (where applicable). Cleaning should be limited

to exterior surfaces only. Removing dust and grease build-

up on the motor assures proper motor cooling.

Motors supplied with grease fittings should be greased

in accordance with the manufacturer’s recommendations.

Greasing motors is only intended when fittings are

provided. Many motors are permanently lubricated,

requiring no additional lubrication.

NOTICE! Do not allow water or solvents to enter

the motor or bearings. Motors and bearings should

never be sprayed with steam, water or solvents.

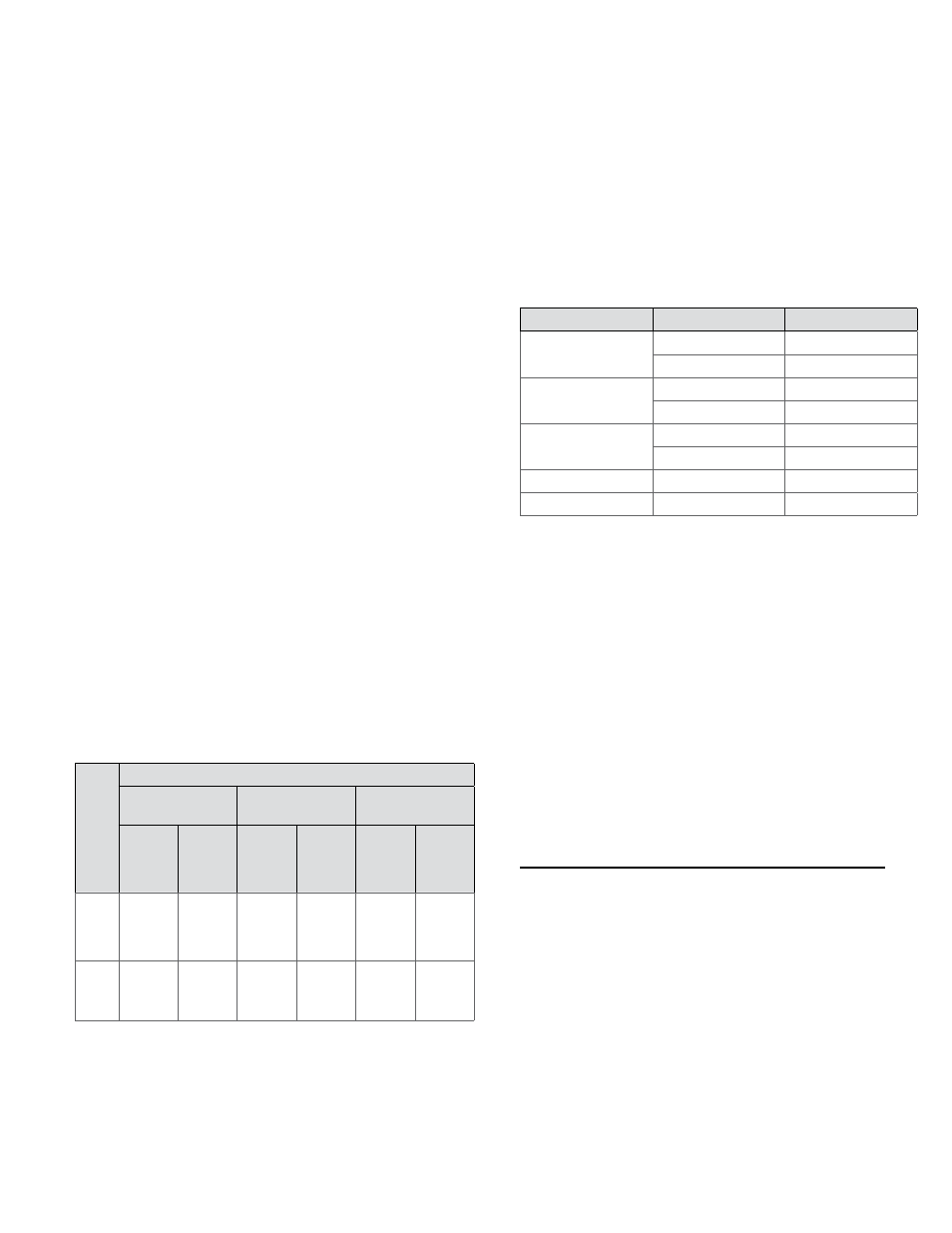

Relubrication Intervals

Service

Conditions

NEMA Frame Size

Up to and

including 184T

213T-365T

404T and larger

1800

RPM

and

less

Over

1800

RPM

1800

RPM

and

less

Over

1800

RPM

1800

RPM

and

less

Over

1800

RPM

Standard

3 yrs.

6

months

2 yrs.

6

months

1 yr.

3

months

Severe

1 yr.

3

months

1 yr.

3

months

6

months

1

months

Wheels

Wheels require little attention when moving clean air.

Occasionally oil and dust may accumulate on the wheel

causing imbalance. When this occurs the wheel and

housing should be cleaned to assure proper operation.

Bearings

The bearings are carefully selected to match the

maximum load and operating conditions of the specific fan