COOK CF-4 User Manual

Ca-4/cf-4, Supplemental installation instructions, Swing out centrifugal blowers

1

Swing Out Centrifugal Blowers

SUPPLEMENTAL INSTALLATION INSTRUCTIONS

CA-4/CF-4

This publication contains the supplemental installa-

tion instructions for standard units of the

CA-4/CF-4-

Swing Out Centrifugal Blowers

. Carefully read this

publication, as well as the CA/CF/CP Installation, Oper-

ation, and Maintenance manual, prior to any installa-

tion or maintenance procedure.

Loren Cook catalog,

CA and CF,

provides additional

information describing the equipment, fan performance,

available accessories, and specification data.

For additional safety information, refer to AMCA publica-

tion 410-96,

Safety Practices for Users and Installers of

Industrial and Commercial Fans

.

All of the publications listed above can be obtained from

Loren Cook Company by phoning 417/869-6474, extension

166; by FAX at 417/832-9431; or by e-mail at info@loren-

cook.com.

For information on special equipment, contact Loren

Cook Company Customer Service Department at 417/869-

6474.

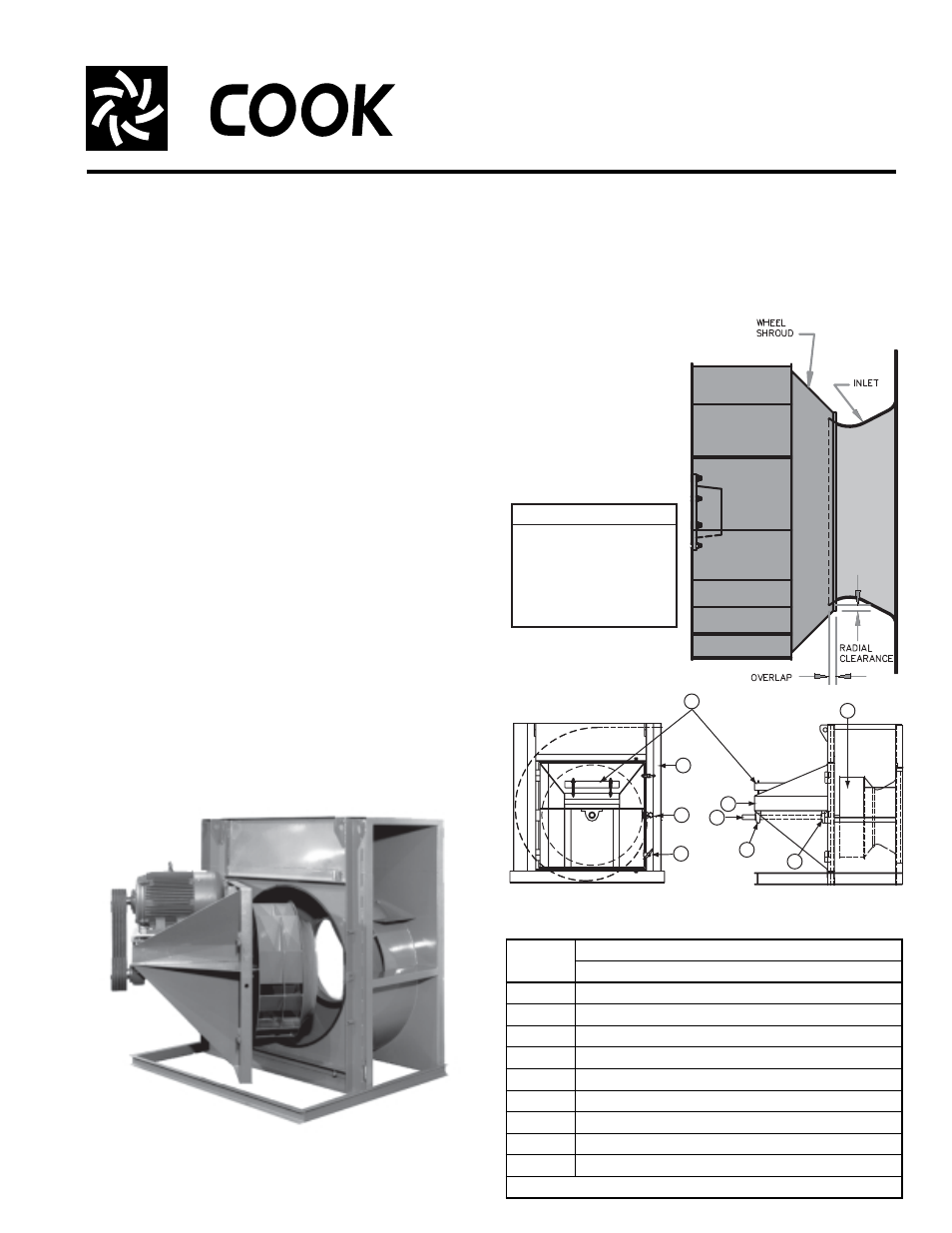

Swing Out Door

All moving parts that require maintenance are mounted

on a hinged door that opens to provide easy access.

• Disconnect power to the unit.

• Clear area around door to allow it to swing open.

• Remove locking pin(s) from door (door latches may

have to be loosened slightly).

• Loosen restraining bolts located at the top and bottom

of door.

• Loosen and remove door latches in steps to insure

even opening of door.

• Pull door open.

• Reverse the steps above to close door.

CA-4 Swing Out

Part No.

Description

Sizes 210-490

e

t

a

l

P

r

o

t

o

M

1

g

n

i

s

u

o

H

2

n

i

P

g

n

i

k

c

o

L

r

o

o

D

3

e

l

d

n

a

H

h

c

t

a

L

r

o

o

D

4

g

n

ir

a

e

B

d

r

a

o

b

n

I

5

g

n

ir

a

e

B

d

r

a

o

b

t

u

O

6

tf

a

h

S

7

8

Bearing Support/Door Assembly

l

e

e

h

W

9

Parts Not Sh own: Motor, Motor Sheave, Inlet Cone, Fan Sheave, Belt Set

1

2

3

4

5

6

7

8

9

Parts List

Front View

Drive Side View

The correct wheel-to-inlet clearance is critical to proper

fan performance. This clearance should be verified

before initial start-up since rough handling during

shipment could cause a shift in fan components. Refer

to wheel/inlet drawing for correct overlap.

Adjust the overlap by loosening the wheel hub and

moving the wheel along the shaft to obtain the correct

value.

A uniform radial gap

(space between the

edge of the cone and

the edge of the inlet) is

obtained by loosening

the inlet cone bolts and

repositioning the inlet

cone.

Size

Overlap

210-245

1/4”

270-300

5/16”

330-365

3/8”

402

7/16”

445-490

1/2”

CA-4/CF-4

IOM Dec 2013