Installation, Rotating parts & electrical shock hazard – COOK HMD EN User Manual

Page 2

2

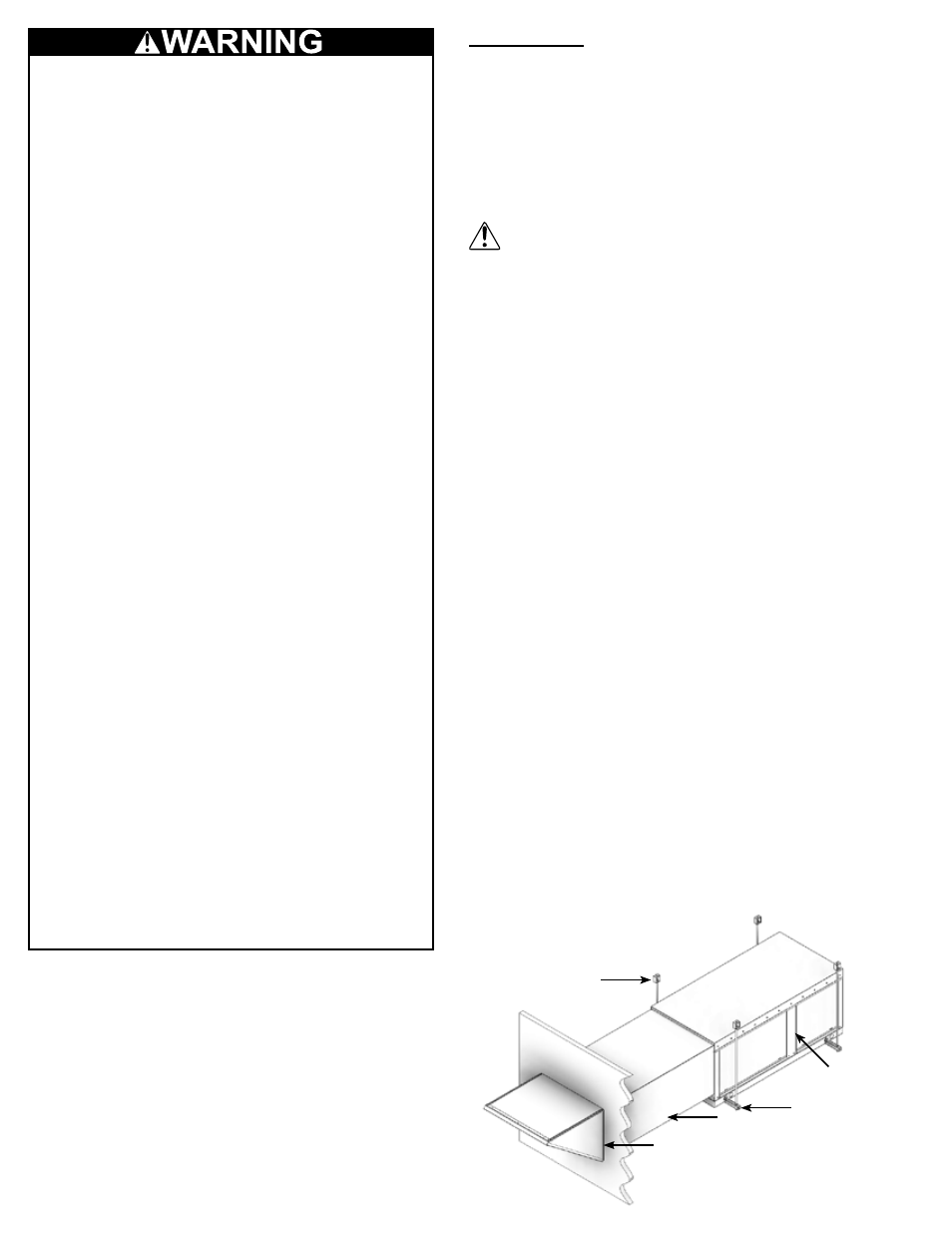

Hanging Mount Example

Hangers

Sealant

Unit

Supports

Duct

Wiring Entry

Installation

Clearance to Combustible / Service Clearances

The minimum distance required between the heater and

adjacent combustible surfaces is 42 inches (1066.8 mm),

on the controls side of the unit, to ensure the adjacent

surface’s temperature does not exceed 90 degrees above

the ambient temperature.

For specific dimensions, refer to the submittal drawing

for the specific fan type.

Installation of the heater (1) in airplane

hangars must be done in accordance with

the Standard for Aircraft Hangars, ANSI/NFPA

409, and (2) public garages must be done in

accordance with the Standard for Parking

Structures, ANSI/NFPA 88A, or the Standard

for Repair Garages, ANSI/NFPA 88B, and with

CAN/CSA B149.1 Natural Cas and Propane

Installation Codes.

NOTICE! Adequate building relief shall be provided

so as to not over pressurize the building when the

heating system is operating at its rated capacity. It

should be noted that this can be accomplished by

taking into account, through standard engineering

methods, the structure’s designed infiltration rate;

by providing properly sized relief openings; or by

interlocking a powered exhaust system; or by a

combination of these methods.

NOTICE! All indoor and outdoor units require

that the air to the heater is ducted directly from

the outdoors. Recirculation of room air is not

permitted.

NOTICE! The heater inlet shall be located in

accordance with the applicable building code

provisions for ventilation air.

NOTICE! Field constructed intake accessories

should be properly designed to minimize the entry

of snow and rain.

NOTICE! If in doubt regarding the application, consult

the heater manufacturer.

Indoor Hanging Arrangement

1. Install threaded hangers from ceiling supports.

When locating hangers, allow enough room to open

access panel(s). Two nuts must be used on the end

Rotating Parts & Electrical Shock Hazard

Improper installation and handling can

result in electric shock, possible injury due

to coming in contact with moving parts, as

well as other potential hazards.

Disconnect electric power before working

on unit.

Follow proper lockout / tagout procedures to

ensure the unit cannot be energized while

being installed or serviced.

A disconnect switch should be placed

near the fan in order that the power can

be swiftly cut off, in case of an emergency

and in order that maintenance personnel

are provided complete control of the power

source.

Verify that the power source is compatible

with the equipment. Grounding for the motor

is required. All field-installed wiring must

be completed by qualified personnel. All

field installed wiring must comply with local

electrical and safety codes, National Electric

Code(NEC), the National Fire Protection

Agency (NFPA 70), and Canadian Electric

Code (CEC) – when in Canada.

Do not allow the power cable to kink

or come in contact with oil, grease, hot

surfaces, or chemicals. Replace cord

immediately if damaged.

Never open blower access doors while the

fan is running.

Failure to follow these instructions could

result in death, serious injury or property

damage.