COOK Constant Pressure Control System User Manual

Constant pressure control system, For electronically commutated motors, Receiving and inspection

®

This installation manual provides information for

installing and configuring the Loren Cook Company

constant pressure control system. The system requires

a Loren Cook Company fan with an Electronically

Commutated, EC, motor with external speed control

capability. The manual does not cover any other

installation details or applications.

Carefully read this publication and any

supplemental documents prior to any

installation or maintenance procedure.

For additional safety information, refer to AMCA

publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans. This

document and all Cook publications may be obtained

from Cook by phoning (417) 869-6474, extension 166; by

FAX at (417) 832-9431; or by e-mail at info@LorenCook.

com. All Cook publications are available on LorenCook.

com.

For information and instructions on special equipment,

contact Cook at (417) 869-6474.

Receiving and Inspection

Carefully inspect the constant pressure control

system and accessories for any damage and shortage

immediately upon receipt of the unit.

Storage

If the constant pressure control system is stored for

any length of time prior to installation store the unit in

its original crate and protect it from dust, debris and the

weather.

Installation

Pressure Tap

The pressure tap is intended to be located in the duct

of the system you want to control. The location is to be

determined by the Engineer that designs the system.

Loren Cook recommends that the tap be located at least

1/3 of the distance from the bottom of the duct.

The pressure tap is mounted per the instructions

included in its packaging.

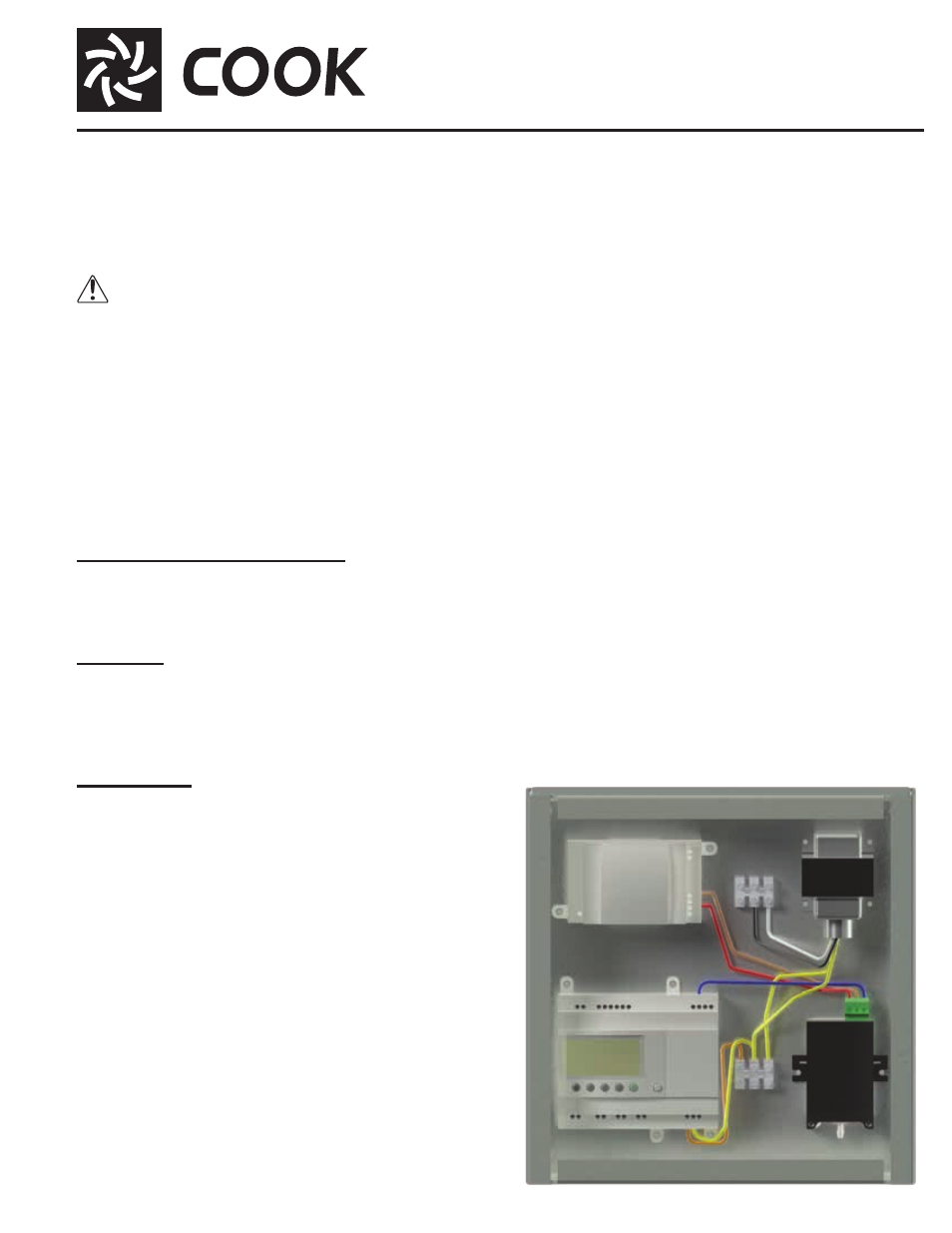

Control Box

The control box should be mounted vertically in a

location that is accessible for operating and configuring

the controller. The control box is provided in a NEMA-

3R configuration that would allow you to mount it in an

outdoor location. The control box should be located

within 100 feet of the fan.

To ensure good response time of the pressure

transducer, the control box should be located within

approximately 50 feet of the pressure tap. If it is not

feasible to locate the control box within 50 feet of the tap,

it may be necessary to re-locate the pressure transducer

Constant Pressure Control System

For electronically commutated motors

Installation and Operation Manual

from within the control box to a location closer to the

pressure tap. It will be necessary to run the wires from

the new pressure transducer location to the control box

as required. The transducer should be located within 100

feet of the control box.

Connect the pressure transducer, either in the control

box or remote mounted, to the pressure tap located in the

system duct using ¼ inch tubing. Depending on whether

the duct is operating under a vacuum or is pressurized,

the tube from the pressure tap will be connected

differently.

• Vacuum:

Connect the tubing to the low connector on the

pressure transducer and leave the high connector

open to the atmosphere. If the control box is not

located in a location that will represent the control

pressure, it may be necessary to use a second

pressure tap and connect the high connector to the

second tap located in the control location.

• Pressurized:

Connect the tubing to the high connector on the

pressure transducer and leave the low connector

open to the atmosphere. If the control box is not

located in a location that will represent the control

pressure, it may be necessary to use a second

pressure tap and connect the low connector to the

second tap located in the control location.

Wiring

See page 2 for the wiring diagram.

Connect the 115 volt power to the disconnect switch,

by others, and then connect the disconnect switch to both

the motor AC power leads and the input connections for

the control box per the wiring diagram.