COOK HMD EN User Manual

Page 5

5

may be experienced during the initial start-up. Left

unchecked, it can cause a multitude of problems

including structural and/or component failure.

Generally, fan vibration and noise is transmitted

to other parts of the building by the ductwork. To

minimize this undesirable effect, the use of heavy

canvas duct connectors is recommended.

7. Measure the motor’s voltage, amps and RPM.

Compare to the specifications. Motor amps can be

reduced by lowering the motor RPM or increasing

system static pressure. Additional starters and

overloads may be provided in the make-up air

control center for optional exhaust blowers. Any

additional overloads must be checked for proper

voltage and amps.

8. Measure the unit’s air volume (cfm) and compare

it with its rated air volume. If the measured air

volume is wrong, adjust the fan’s RPM by changing/

adjusting the drive. The most accurate way to

measure the air volume is by using a Pitot traverse

Testing Inspection

All components of this or any other gas-

fired heating unit must be leak tested prior

to placing the unit into operation. The

factory piping has been checked for leaks

but should be rechecked due to shipping &

installation issues. The field-installed shutoff

valve should also be checked.

A soap & water solution should be used to

perform this test.

Never test for gas leaks with a flame.

When leak testing pressures that are less

than or equal to 14 in. wc (3.5 kPa), first

close the field-installed shutoff valve to

isolate the unit from gas supply line.

When leak testing presures that are more

than 14 in. wc (3.5 kPa), close the field-

installed shutoff valve, disconnect the

furnace & gas train from the gas supply line

& plug the supply line before testing.

All piping should be clean & free of any

foreign matter, which may damage the

values, regulators or burner.

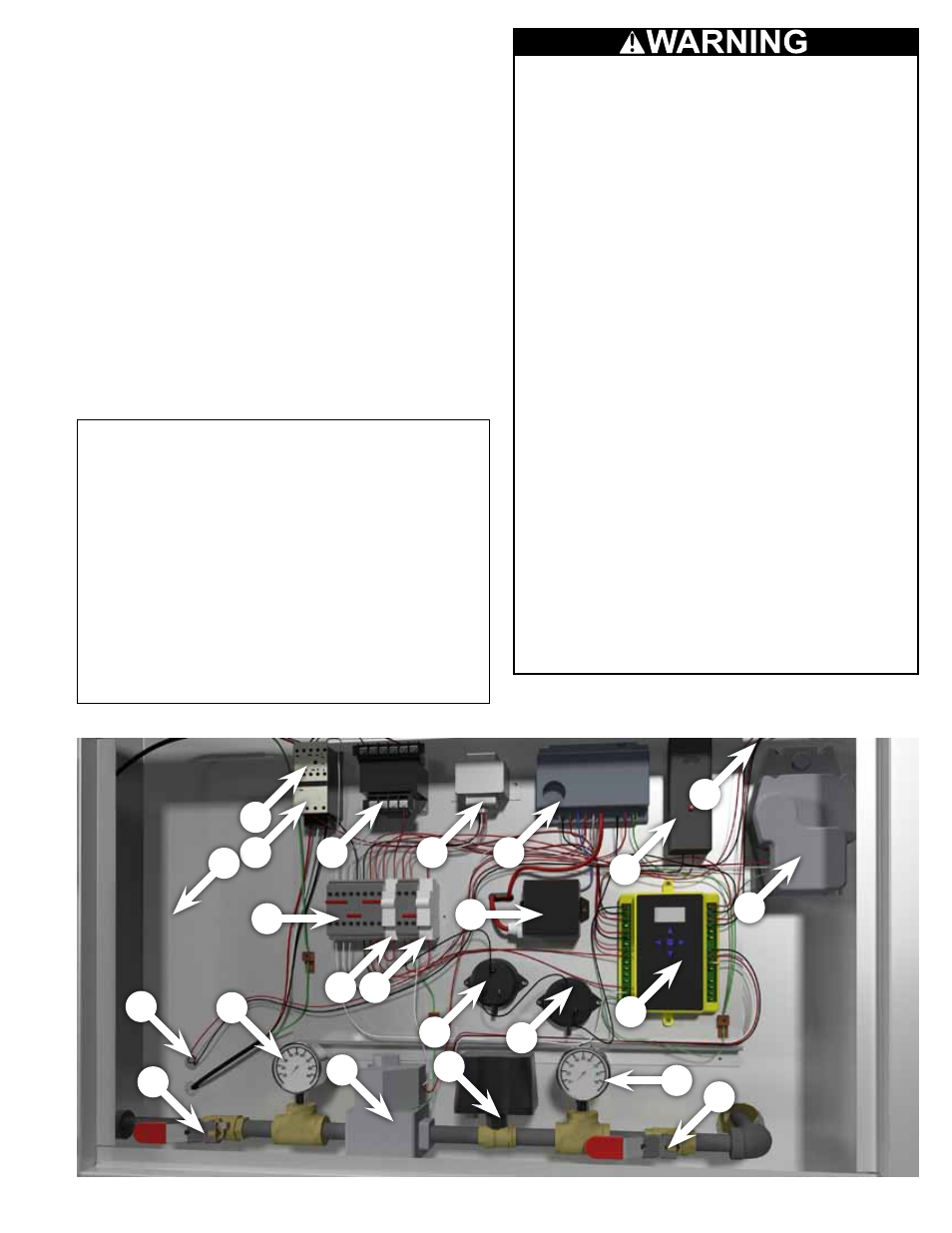

Control Panel

Control Panel Parts

1. Contactor

2. Overload

3. Three phase

transformer #A

4. 120 - 24v

transformer #B

5. Ignition control

6. High Temp Overload

7. Mild weather thermostat

to damper

8. Damper motor

9. Terminal blocks

10. Circuit breaker

11. Override switch

12. 120v spark ignitor

13. Pressure sensing probe

(high)

14. Pressure sensing probe

(low)

15. Temperature controller

16. Thermostat to blower

17. Safety Shut off valve

18. Pressure gauge

19. Gas valve

20. Modulating gas valve

21. Pressure gauge

22. Safety Shut off valve

23. Optional V.F.D. here

1

2

3

4

5

6

7

8

9

12

10 11

15

13

17

16

18

19

22

20

21

14

23