COOK Laboratory Exhaust User Manual

Laboratory exhaust, Supplemental installation and maintenance manual

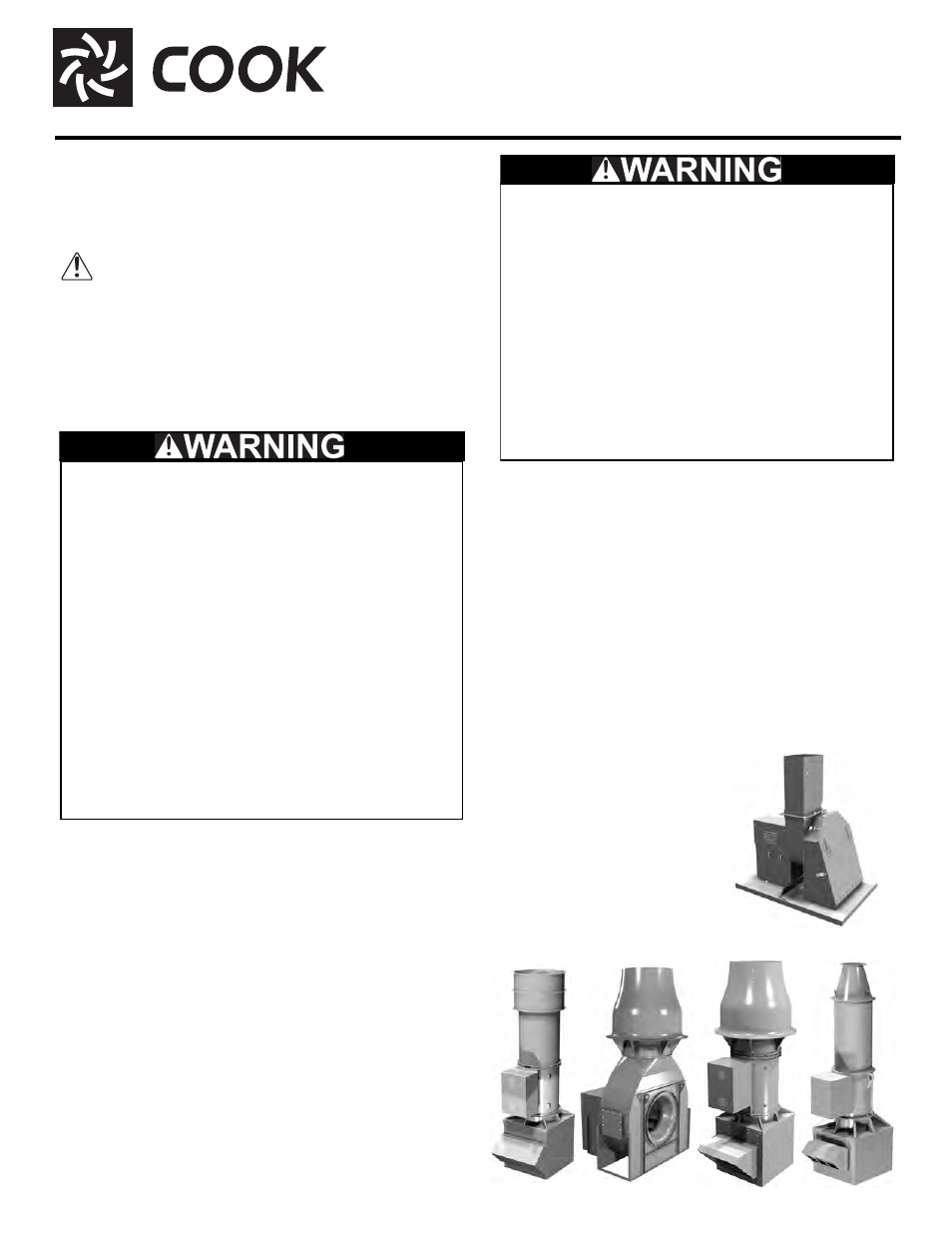

TCNHBLE

®

Vari-Plume

®

and Laboratory Exhaust Products

SUPPLEMENTAL INSTALLATION AND MAINTENANCE MANUAL

Laboratory Exhaust

Installation

The unit should be installed on a curb/base that is securely

attached to the roof structure per contract documents and local

codes. If the curb is provided by Loren Cook, the curb should be

attached per the provided submittal document by welding to the

roof structure.

For curb mounted assemblies, the unit should be securely

fastened to the curb using minimum ¼” x ¾” sheet metal screws

using pre-punched holes in the curb cap. If pre-punched holes

are not provided, use a minimum of 2 screws per side and a

maximum of 12” spacing.

Drain Connections

Loren Cook lab exhaust fans all have drains as standard

construction features. These drains should be properly

connected to a drainage system to ensure that the run off from

the units is disposed of properly.

The connection should include a

trap system (Figure 5) that is sized

adequately to not allow for air

leakage under the system pressure.

Dimension A and B should be

double the total static pressure for

the unit.

The attachment of roof mounted fans to the roof

curb as well as the attachment of roof curbs to the

building structure must exceed the structural

requirements based on the environmental loading

derived from the applicable building code for the

site. The local code official may require variations

from the recognized code based on local data. The

licensed engineer of record will be responsible for

prescribing the correct attachment based on

construction materials, code requirements and

environmental effects specific to the installation.

Failure to follow these instructions could result in

death or serious injury.

QMXVP

CPSLE

This publication contains supplemental installation and

maintenance instructions for Vari-Plume

®

and Laboratory Exhaust

units:

• CPSLE

• QMXLE

• TCNHBLE

• CAVP

• QMXVP

Carefully read this publication and any

supplemental documents prior to any

installation or maintenance procedure.

Loren Cook Company’s Laboratory Exhaust catalog / brochure,

as well as the documents related to each unit (such as CPS),

provide additional information describing the equipment, fan

performance, available accessories, and specification data.

For additional safety information, refer to AMCA Publication

410-96, Safety Practices for Users and Installers of Industrial and

Commercial Fans.

Handling and Lifting

Always lift fan by lifting lugs.

NOTICE!

Never lift unit by shaft,

motor, housing, or nozzle.

The units may be shipped in sections and each section should

be lifted into place using the provided lifting lugs. If the unit is to be

lifted assembled, lift the unit with lifting lugs attached to the fan

housing using a spreader bar as required to ensure no damage is

incurred on the nozzle assembly.

All Vari-Plume

®

and Laboratory Exhaust units are designed to

be self-supporting, without the use of guy wire, when installed

according to the instructions within this document. The roof curb

must be securely installed prior to fan installation according to the

curb manufacturer’s recommendations.

Unit Assembly

If unit is shipped in sections, assemble unit starting at the

lowest level moving up the assembly. Each section should have a

pre-installed gasket that must be present to ensure proper sealing

of unit. If the gasket is damaged or missing, caulk may be used to

seal the sections by applying between the bolted sections. Once

the gasket/caulk has been verified, assemble the sections and

bolt together with the provided hardware.

Rotating Parts & Electrical Shock Hazard:

Disconnect electric power before working on unit.

Follow proper lockout / tagout procedures to ensure

the unit cannot be energized while being installed or

serviced.

A disconnect switch should be placed near the fan in

order that the power can be swiftly cut off, in case of

an emergency and in order that maintenance

personnel are provided complete control of the

power source.

Grounding is required. All field-installed wiring must

be completed by qualified personnel. All field-

installed wiring must comply with National Electric

Code (NFPA 70) and all applicable local codes.

Failure to follow these instructions could result in

death or serious injury.

CAVP

QMXLE