Water conditioning – Blodgett SN-E Series User Manual

Page 7

OM-SN-E 5

It is essential to supply the steam generator with water that will not form scale.

Even though the steam generator is engineered to minimize scale formation, scale

development depends on the hardness of your water and the number of hours per day

you operate the equipment.

Most water supplies are full of minerals which form scale. It is this scale which could

lead to an early component failure.

Your water utility can tell you about the minerals in your water. The water going to

the steam generator should have no more than 10 to 30 parts per million (ppm) total

dissolved solids (TDS) and should have a pH (acidity rating) of 7.0 or higher. Please

follow these simple precautions:

1. The best way to prevent scale is to use a water treatment system which has

been specifically designed for steamers and combination ovens. Do not rely on

unproven water treatment systems sold for scale prevention and removal. They

are not specifically designed to work with steamers and combination ovens.

2. A well-maintained water treatment system and a regular cartridge replacement

schedule is essential.

3. Using a water treatment system will provide longer steam generator/boiler life,

higher steam capacity, and reduce maintenance requirements.

4. If you notice a slowdown in steam production or an increase in deliming, have

the steamer checked for scale build-up. This could be an indication that the

water treatment cartridges need replacing. Heavy scale reduces the unitʼs ability

to boil water, and can even cause component failure.

MINIMIZE SCALE PROBLEMS BY USING AND MAINTAINING A SOFTENER AND BY

CLEANING (DELIMING) THE STEAMER REGULARLY.

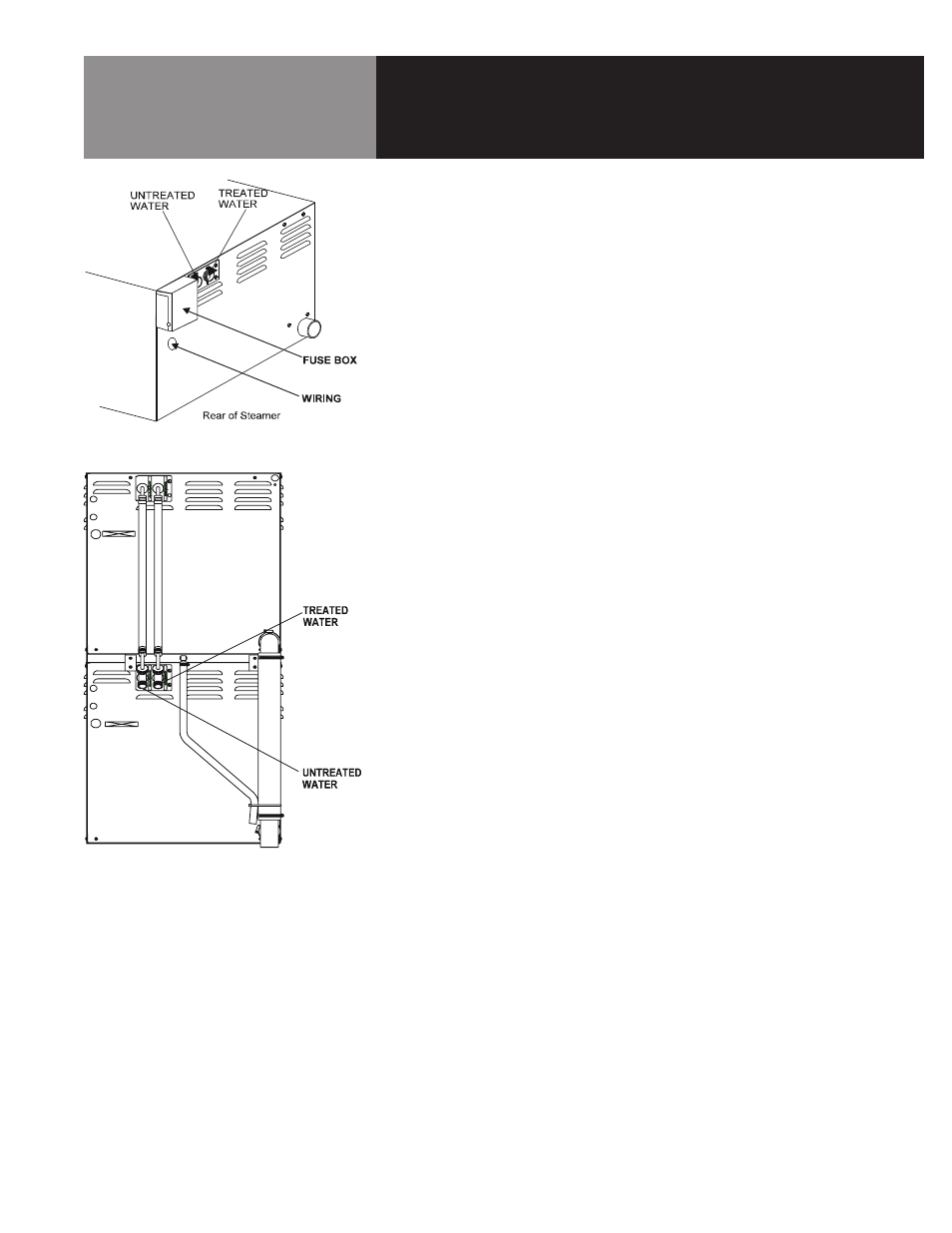

On both the 3-pan and 5-pan, the dual water connections are side by side on the rear

of the unit. When seen from the back of the unit, the treated (softened) water intake is

on the right.

Water Conditioning

Stacked steamers