1. troubleshooting chart – Campbell Scientific OBS500 Smart Turbidity Meter with ClearSensor Technology User Manual

Page 50

OBS500 Smart Turbidity Meter with ClearSensor™ Technology

The following three tests are used to diagnose malfunctions of an OBS500.

1. The

Finger-Wave Test is used to determine if an OBS sensor is ‘alive’.

Power the OBS sensor and connect datalogger (see Section 7.2, Device

Configuration Utility). Wave your finger across the sensor window about

20 mm away from it. The datalogger should show the output fluctuating

from a few TU to the full-scale signal. If there are no signal fluctuations

of this order, there is a problem that requires attention.

2. The

Shake Test is done to determine if water has leaked inside the

pressure housing. Unplug the cable and gently shake the sensor next to

your ear and listen for sloshing water. This test gives a false negative

result when the amount of water in the housing is large enough to destroy

the circuit but too small to be audible.

3. A

Calibration Check is done to verify if a working OBS sensor needs to

be recalibrated. In order to be meaningful, the user must have a criterion

for this test. For example, this criterion might be 5%. The sensor is

placed in calibration standards with the 1

st

and 2

nd

TU values listed in

FIGURE 7-5 and the datalogger readings are logged. If either reading

differs by more than 5% from ones reported on the factory calibration

certificate, or the user’s own calibration data, the sensor should be

recalibrated. If the first two calibration points fall within the acceptance

criterion, then the third value can be tested. The recommended frequency

for calibration checks is quarterly when an OBS sensor is in regular use.

Otherwise it should be performed prior to use. Calibration checks can be

done in the field.

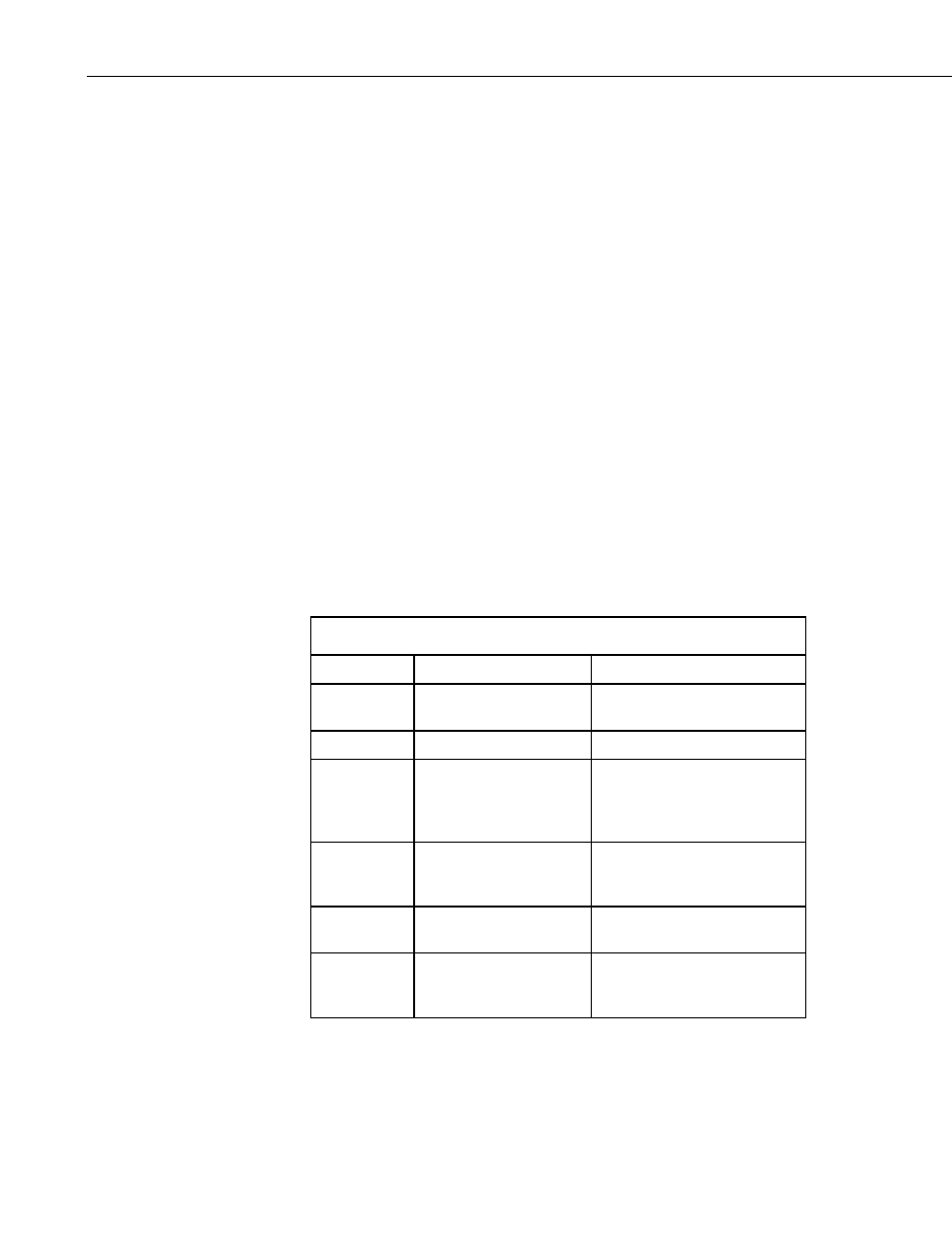

TABLE 10-1. Troubleshooting Chart.

Fault

Cause of Fault

Remedy

Fails finger-

wave test

No power, dead battery

Replace battery and reconnect

wires.

Plug not fully seated

Disconnect and reinsert plug.

Sensor broken

Visually inspect for cracks.

Return OBS500 to

manufacturer if cracks are

found.

Electronic failure. Unit

draws less than 11 mA or

more than 40 mA.

Return OBS500 to

manufacturer.

Fails shake

test

Sensor leaked

Return OBS500 to

manufacturer.

Fails

calibration

check

Aging of light source

causes it to become

dimmer with time

Recalibrate (see Section 7.5,

Calibration).

40