2 sediment, 1 dry-sediment calibration, Sediment – Campbell Scientific OBS500 Smart Turbidity Meter with ClearSensor Technology User Manual

Page 36: Dry-sediment calibration, 7. obs500 in 500-tu amco clear, Turbidity standard in 100-mm, Black polyethylene calibration cup, Figure 7-7

OBS500 Smart Turbidity Meter with ClearSensor™ Technology

6. Repeat steps 2, 3, 4, and 5 for the other standards.

7. Perform 2

nd

-order polynomial regressions on the calibration data to get the

coefficients for converting OBS signals to TU values.

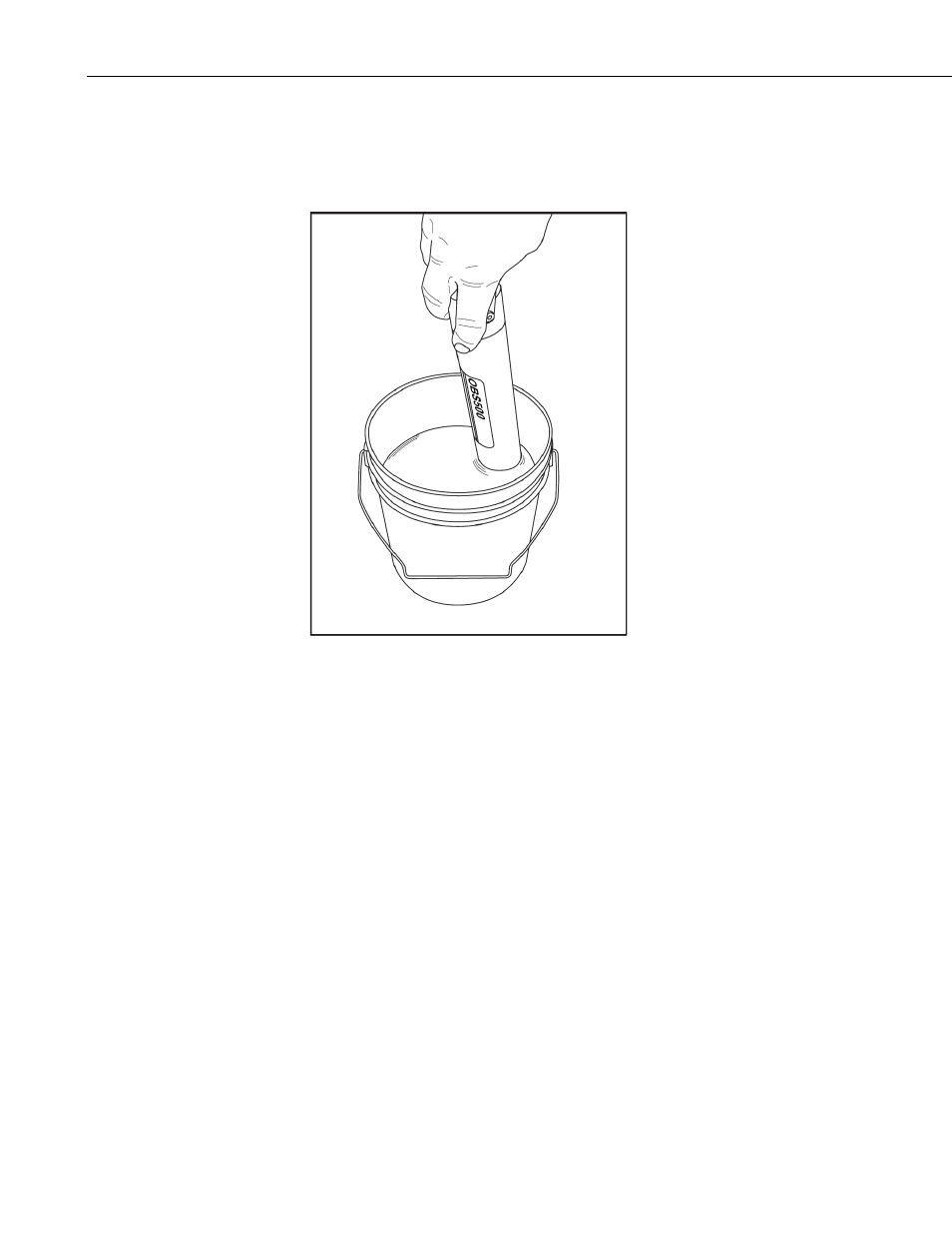

FIGURE 7-7. OBS500 in 500-TU AMCO Clear

®

turbidity standard in

100-mm black polyethylene calibration cup

7.5.2 Sediment

There are three basic ways to calibrate an OBS sensor with sediment. These

are described in the following sections. However, only the procedures for dry-

sediment are explained in this manual. Typically, the sensor will record in

turbidity units and the relationship to suspended sediment is calculated in a

spread sheet or database after the data is retrieved to a computer.

7.5.2.1 Dry-Sediment Calibration

Dry-sediment calibration is a calibration performed with sediment that has

been dried, crushed, and turned to powder. This is the easiest calibration to do

because the amount of sediment can be determined accurately with an

electronic balance and the volume of water in which it is suspended can be

accurately measured with volumetric glassware. Of the three methods, dry-

sediment calibration causes the greatest physical and chemical alteration of the

sediment. Alteration of the sediment size as a result of processing can

significantly affect the calibration slope. FIGURE 7-5 shows, for example, that

reducing the grain size by a factor of two during grinding can increase OBS

sensitivity by a factor of two.

26