Horner APG XLt OCS HE-XT102-10 User Manual

Page 4

PAGE

4

21

AUGUST

2007

MAN0864-02

HE-XT102-10

Specifications / Installation

7 Analog

Conditioning

7.1 Filter

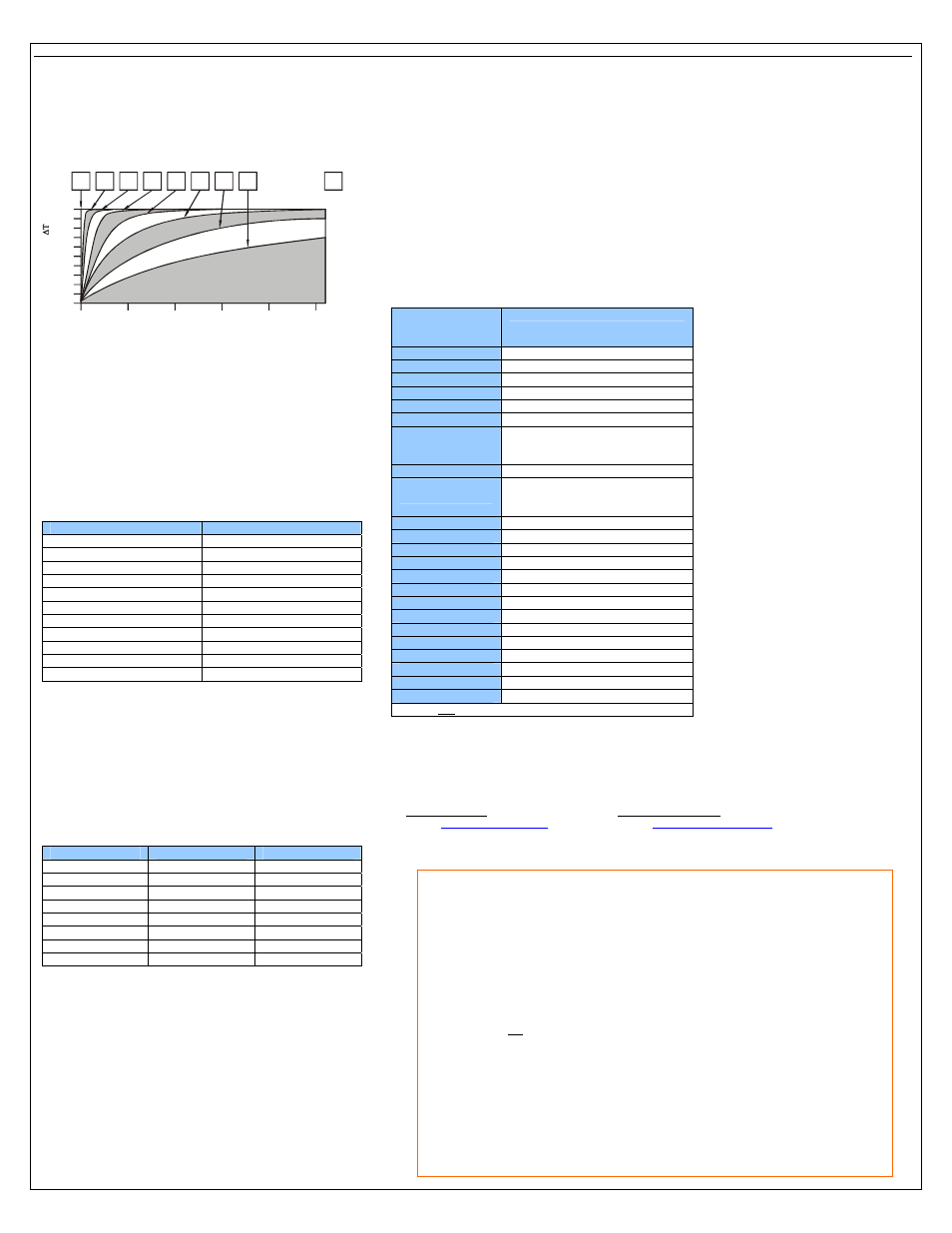

Filter Constant sets the level of digital filtering according to the

following chart.

Digital Filtering

. The illustration above demonstrates the effect of

digital filtering (set with Filter Constant) on module

response to a temperature change.

It is recommended that the filter constant for the HE-XT102-10 be set

to a value of 7. This will minimize noise and jitter, improve effective

resolution, and provide adequate speed for most temperature monitor

and control applications.

7.2 Thermistor

Linearization

Thermistors are measured using a half-bridge circuit that exhibits

variable resolution and the associated increased measurement

range.

Temperature, degrees C

Resolution, degrees C

-55 1.05

-35 0.36

-15 0.17

5 0.11

25 0.1

45 0.13

65 0.22

85 0.30

105 0.55

125 0.85

145 1.35

Best resolution is at 25°C, 77°F. With a constant 0.1°C resolution

circuit, the measurement range would only extend from –26°C to

+76°C.

Linearization must be performed by the user in the ladder application

code, using 26 internal %R registers per channel. The example

below uses %R1-26 to linearize one channel - %AI1. Linearization

consists of the following example steps.

1)

Load the desired linearization coefficients into a table on

First Scan using a Move Constant Data block.

Registers (Real)

Degrees C

Degrees F

R0011 -1.94454e-028

-3.50017e-028

R0013 2.40268e-023

4.32483e-023

R0015 -1.24101e-018

-2.23381e-018

R0017 3.46655e-014

6.23979e-014

R0019 -5.69403e-010

-1.02493e-009

R0021 5.62368e-006

1.01226e-005

R0023 -0.0353121

-0.0635617

R0025 163.878 326.981

2)

Load %AI0001 into %R0001 as a Real.

3)

Perform the Real Math Expression

4)

%R3 = (((%R11*%R1+%R13)*%R1+%R15)*%R1+%R17)

5)

Perform the Real Math Expression %R5 =

(((%R3*%R1+%R19)*%R1+%R21)*%R1+%R23)*%R1+

%R25

6)

Load %R0005 result into another register such as

%R0007 to save the temperature value.

7)

Steps 2 though 5 can be on a single rung.

The expression rung may be copied, substituting %AI0002 and %R00011 for %AI0001 and

%R0007, and used to linearize the second channel. Contact Horner APG Technical Support

for an example file containing the above program.

7.3 Thermistor

types

The HE-XE102-10 with the given example ladder code supports Kele Engineering Precon Type III, 10 KΩ

thermistors. It also directly supports the following 10 KΩ (Beta=3574) thermistors from Yellow Springs

Instruments (YSI).

44006 46006

44106 46031

44406 46041

44031 44907

45006 44908

8 I/O

Register

Map

Registers

Description

%I1 to %I12

Digital Inputs

%I32 Output

Fault

%I25 to %I31

Reserved

%Q1 to %Q16

Digital Outputs

%Q17

Clear HSC1 accumulator to 0

%Q18

Totalizer: Clear HSC2

Quadrature 1-2: Accumulator 1

Reset to max – 1

%Q19

Clear HSC3 Accumulator to 0

%Q20

Totalizer: Clear HSC4

Quadrature 3-4: Accumulator 3

Reset to max – 1

%Q21 to %Q32

Reserved

%AI1 to %AI4

Analog inputs

%AI5, %AI6

HSC1 Accumulator

%AI7, %AI8

HSC2 Accumulator

%AI9, %AI10

HSC3 Accumulator

%AI11, %AI12

HSC4 Accumulator

%AQ9 to %AQ14

Analog outputs

%AQ1, %AQ2

PWM1 Duty Cycle

%AQ3, %AQ4

PWM2 Duty Cycle

%AQ5, %AQ6

PWM Prescale

%AQ7, %AQ8

PWM Period

Note:

Not all XLT units contain the I/O listed in this table.

9 Technical

Support

For assistance and manual updates, contact Technical Support at the following locations:

North America:

(317) 916-4274

www.heapg.com

email:

Europe:

(+) 353-21-4321-266

www.horner-apg.com

email:

10

Safety Precautions for Installation and Connections to XLe

60

20

100

40

80

20

0

10

100

90

80

70

60

50

40

30

Scans

0

1

2

3

4

5

6

0

7

%

C

o

m

p

let

e

[

]

Filter

Constant

All applicable codes and standards need to be followed in the installation of this

product.

Adhere to the following safety precautions whenever any type of connection is

made to the module:

9

Connect the safety (earth) ground on the power connector first before making

any other connections.

9

When connecting to electric circuits or pulse-initiating equipment, open their

related breakers.

9

Do not make connections to live power lines.

9

Make connections to the module first; then connect to the circuit to be monitored.

9

Route power wires in a safe manner in accordance with good practice and local

codes.

9

Wear proper personal protective equipment including safety glasses and

insulated gloves when making connections to power circuits.

9

Ensure hands, shoes, and floor are dry before making any connection to a power

line.

9

Make sure the unit is turned OFF before making connection to terminals.

9

Make sure all circuits are de-energized before making connections.

9

Before each use, inspect all cables for breaks or cracks in the insulation.

Replace immediately if defective.