Horner APG XLe OCS HEXE220C015 User Manual

Page 2

MAN0810-10-EN

Specifications / Installation

__________________________________________________________________________________________________________________________________________________________________

12/18/2008

Page 2 of 4 ECN # 947

2

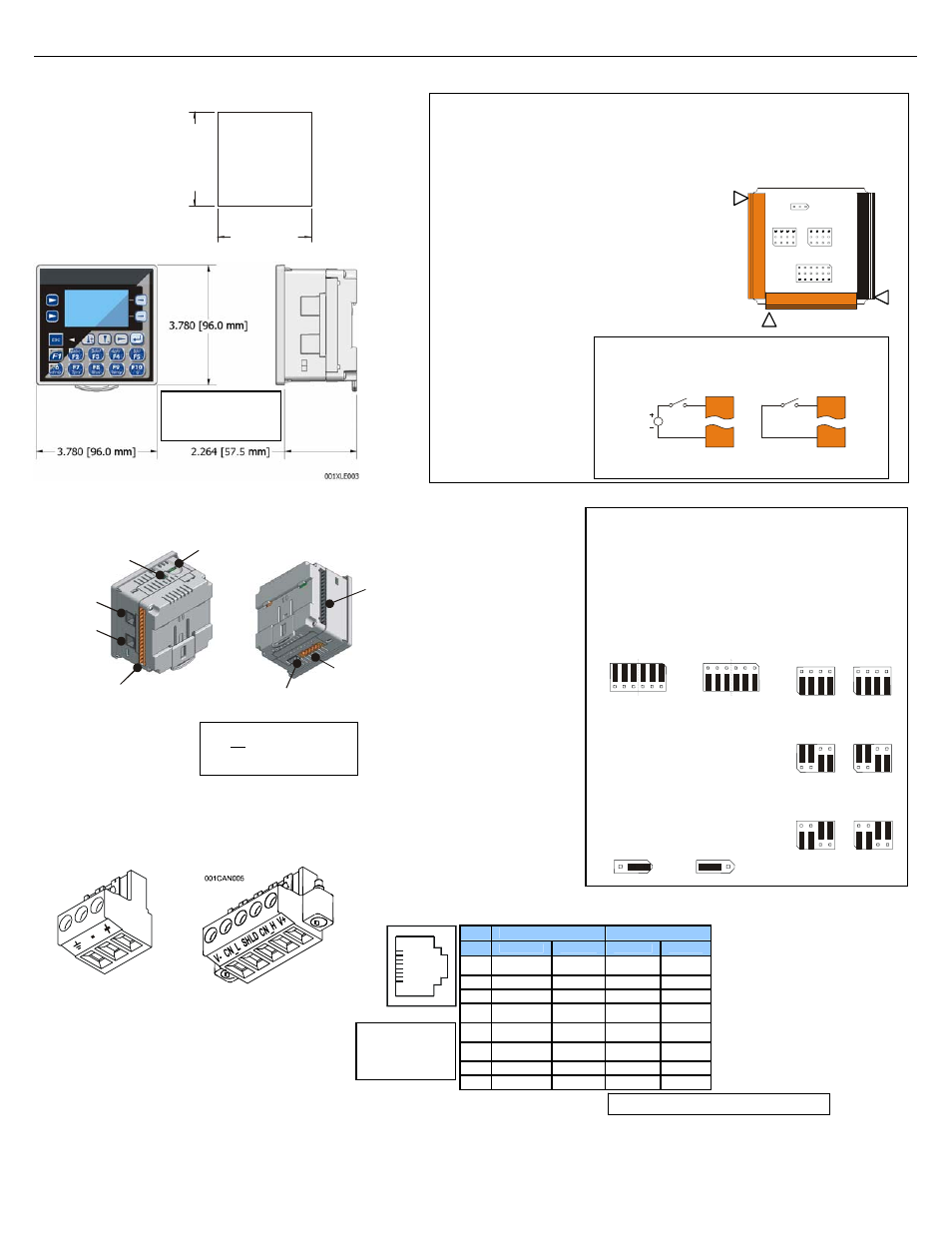

Panel Cut-Out and Dimensions

Note: Max. panel thickness: 5 mm.

3

Ports / Connectors / Cables

Note: The case of the XLe is black, but for clarity, it is shown in a lighter gray color.

4.1

I/O Jumpers Settings (JP1 – JP4)

3.62

2

[

9

2m

m

]

3.622 [92mm]

001XLE002

Refer to XLe/XLt User

Manual for panel box

information and a handy

checklist of requirements.

Note:

The tolerance to meet

NEMA standards is

± 0.005” (0.1 mm).

To Remove Back Cover:

Unscrew 4 screws located on

the back of the unit.

Remove Cover.

CAUTION:

Do not over tighten screws

when replacing the back cover.

001ACC009

Power Connector

Power Up:

Connect to Earth Ground.

Apply 10 - 30 VDC.

Screen lights up.

Torque rating 4.5 – 7 Lb-In

(0.50 – 0.78 N-m)

CAN Connector

Use the CAN Connector when

using CsCAN network.

Torque Rating 4.5 – 7 Lb-In

(0.50 – 0.78 N-m)

I/O Jumpers (Not Shown): I/O Jumpers (JP) are located

internally. To access, remove back cover of unit.

Wiring Connectors (J1 – J3), I/O Jumpers (JP1 – JP4), and

External Jumpers (RS-485) are described in the Wiring and

Jumpers section of this document.

Note: The Cscape Module Setup configuration must match

the selected I/O (JP) jumper settings.

Negative Logic

Positive Logic

JP1 Digital DC Inputs

Default

I1

0V

001XLE036

12-24VDC

I1

0V

Positive Logic In Negative Logic In

Positive Logic vs. Negative Logic Wiring

The XLe can be wired for Positive Logic inputs or

Negative Logic inputs.

Memory Slot:

Uses Removable Memory for

data logging, screen captures,

program loading and recipes.

Horner Part No.: HE-MC1

Serial Communications:

MJ1: (RS-232 / RS-485) Use for

Cscape programming and

Application-Defined

Communications.

MJ2: (RS-232 / RS-485) Use for

Application-Defined

Communications.

J1

J2

J3

JP2

JP1

JP3

JP4

001XLE030

Location of I/O jumpers (JP)

and wiring connectors

(J1 – J3).

Wiring Specifications

For I/O wiring (discrete), use the following wire type or

equivalent: Belden 9918, 18 AWG (0.8 mm

2

) or larger.

For shielded Analog I/O wiring, use the following wire type

or equivalent: Belden 8441, 18 AWG (0.8 mm

2

) or larger.

For CAN wiring, use the following wire type or equivalent:

Belden 3084, 24 AWG (0.2 mm

2

) or larger.

CURRENT

(20mA)

VOLTAGE

(10V)

JP4

ANALOG OUTPUT SETTING

VOLTAGE OR CURRENT

AQ2

AQ1

AQ2

AQ1

Default

Analog In Settings

AI1 AI2

JP2

JP3

RTD (PT100)

T1

T2

JP2

JP3

T/C/100mV

T1

T2

Note: When using JP4 (output) or JP2 / JP3

(inputs), each channel can be independently

configured. For example, JP2 can be

configured for 10 V and JP3 can be configured

as an RTD.

JP2

JP3

10V/20mA

MA1/V1

MA2/V2

Default

MJ1

(RS-232 / RS-485)

MJ2

(RS-232 / RS-485)

J1

I/O

Jumper

Memory Slot

001XLE029-R2

J2

I/O

Jumper

NET 1

(CsCAN)

Power

DIP

Switch

Note – Your keypad overlay

appearance may differ.

Standard US/EU overlays

pictured here for example

.

* +5Vdc 60mA Max on XLe Rev E and later

Pin

MJ1 Pins

MJ2 Pins

Signal

Direction

Signal

Direction

8

TXD OUT TXD OUT

7

RXD IN RXD IN

6

0 V

Ground

0 V

Ground

5*

+5 60mA

OUT

+5 60mA

OUT

4

RTS OUT TX- OUT

3

CTS IN TX+

OUT

2

RX- / TX-

IN / OUT

TX-/RX-

IN

1

RX+ / TX+

IN / OUT

TX+/RX+

IN

1

8

Serial

Communications:

MJ1 and MJ2

(RS-232 / RS-485)

4

Wiring and Jumpers

• Wire according to the type of inputs / outputs used and select the appropriate jumper

option. Use Copper Conductors in Field Wiring Only, 60/75° C