Red Lion GEMINI 52 User Manual

Page 4

4

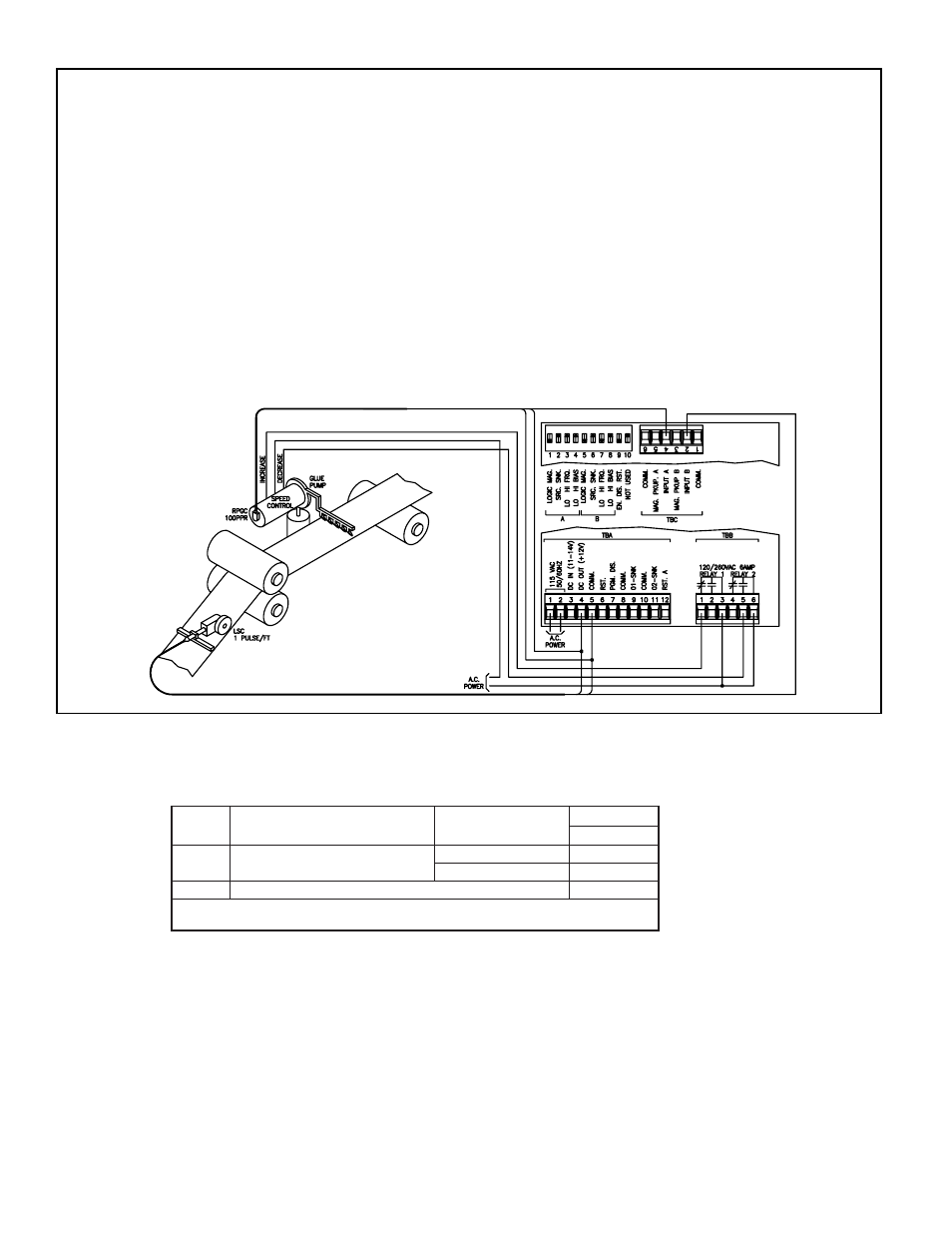

This application involves the monitoring and control of a glue allocation

process on a continuous web of industrial grade paper. In this case, the desired

results are to maintain a flow of glue between 2.00 and 2.50 gallons per 100

feet of web. To accomplish this, a Gemini 5200 is used in the A/B ratio

indicator mode, which will yield a direct readout in gallons per 100 feet to the

nearest hundredth gallon.

Channel A is connected to a 100 PPR RPGC pulse generator which is

mounted to the shaft of the glue pump. The pump delivers 0.38 gallons per

shaft revolution. Therefore, a scale factor of 0.3800 is programmed into

Channel A of the Gemini 5200 to yield 38 pulses per revolution. This

effectively multiplies the glue flow rate by 100 which allows a decimal point

to be programmed to the left of digit 2, producing a display of gallons per

second to the nearest hundredth gallon on Channel A.

A length sensor providing one pulse per foot of web material is fed into

Channel B of the Gemini. The Channel B scale multiplier is programmed for

x100 to produce a display reading of feet per second to the nearest hundredth

on Channel B.

The Gemini 5200 performs the A/B calculation and displays the ratio in

gallons per feet on Channel C. Since the application requires resolution in

hundredths of gallons, the Channel C display must be multiplied by 100 to

provide such resolution. However, the desired readout is not in terms of gallons

per foot, but rather gallons per 100 feet which requires the display to be

multiplied by another factor of 100. Therefore, the Channel C scale multiplier

is programmed for x10,000 (i.e. 100 x 100) which provides the desired

Channel C reading of gallons per 100 feet to the nearest hundredth gallon.

The relay outputs of the Gemini 5200 are connected to a speed control

mechanism on the glue pump which increases or decreases the glue flow rate

while the appropriate relay contacts are closed. Both preset outputs are assigned

to Channel C in the boundary mode of operation and are programmed for the

upper and lower acceptable limits of the glue flow rate. In this case, the pump

initially increases the output flow until a rate of 2.00 gallons per 100 feet is

reached, at which time Output 1 toggles to prevent further increase in speed.

If the flow rate reaches or exceeds 2.50 gallons per 100 feet, Output 2 will

toggle and send a correction signal to the pump until the speed slows to

acceptable limits. If the rate falls back below the lower limit, Output 1 again

toggles to speed-up the glue pump.

The Gemini 5200 can be used in this type of application to indicate and

control virtually any process that requires the distribution of a specified

amount of material in relation to another specified amount of material.

ORDERING INFORMATION

GEMINI 5200 APPLICATIONS (Cont’d)

CONTROLLING THE RELATIONSHIP BETWEEN SPECIFIED AMOUNTS OF MATERIAL

For more information on Pricing, Enclosures & Panel Mount Kits refer to the RLC Catalog or contact

your local RLC distributor.

GEM52

Gemini 5200

No

GEM52060

Yes

GEM52160

_

Gemini 5200 Relay Board

RLYBD002

W/20 mA CURRENT LOOP

115/230 VAC

MODEL NO. DESCRIPTION

PART NUMBERS