Programming, Gemini 5200 applications – Red Lion GEMINI 52 User Manual

Page 3

3

PROGRAMMING

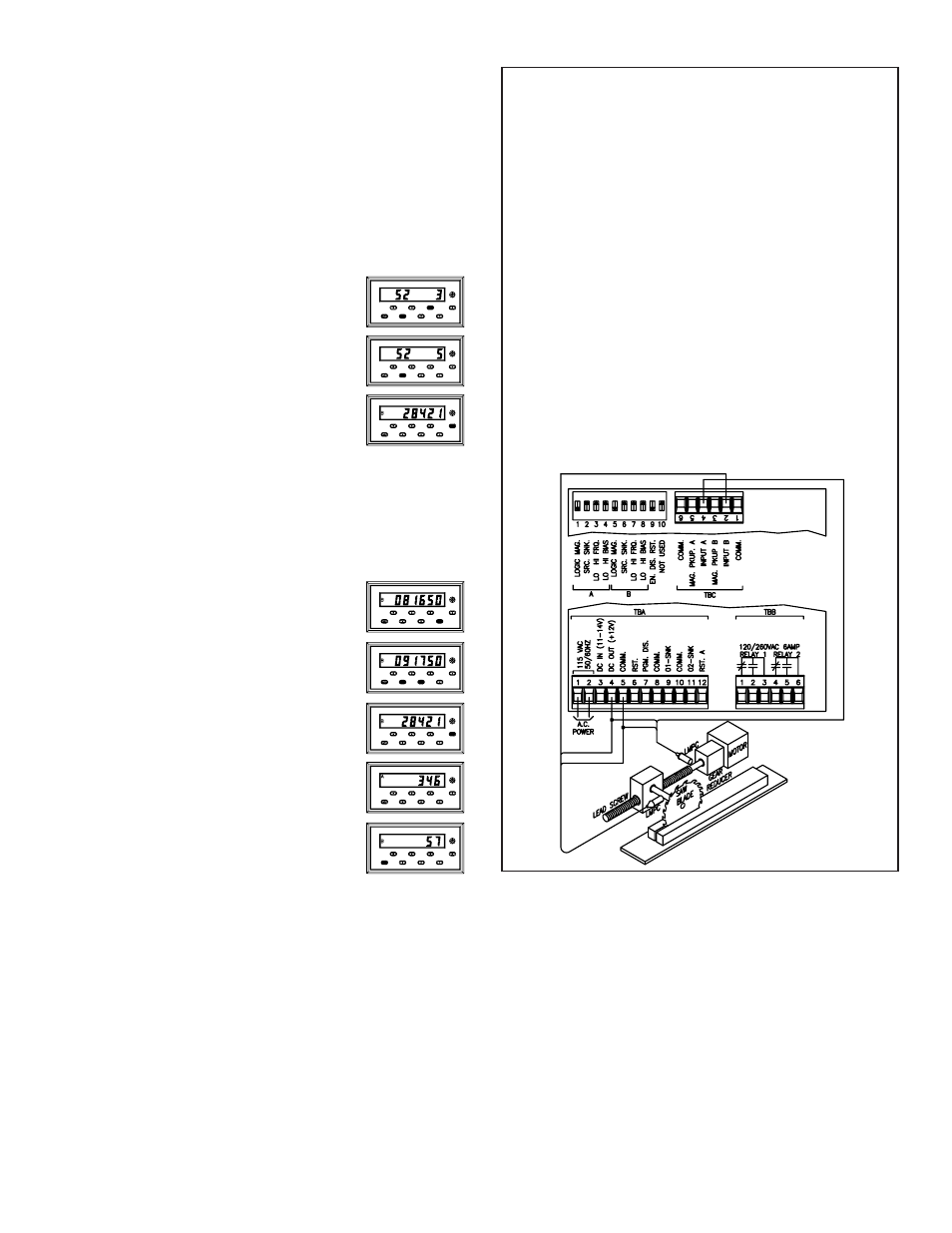

The Gemini 5200 input circuit set-up is programmed using DIP switches on

the rear of the unit. All other functions are programmed through the front panel

pushbuttons.

To program or interrogate a function, the user first enters a two-digit function

code. The unit will then display that function code along with a single-digit

mode identifier.

EXAMPLE: The function code representing “Output 1 Termination Modes” is

52. The mode identifiers for this function are:

3. Terminate at Manual Reset

4. Terminate at Manual Reset End

5. Terminate after Timed Output 1

6. Boundary

To interrogate the output termination mode, Press “5”,

then “2”:

Unit displays the function code along with mode

identifier 3 (Terminate at Manual Reset).

To change this mode to “Terminate After Timed

Output”, Press “5”:

To enter and save the new mode, Press “E”:

Unit enters new mode and returns display to the present

selected display value.

The most commonly used functions, Presets and Scale Factors, are initialized

through single front panel pushbuttons rather than a two-digit function code.

Pressing the “1” or “3” pushbuttons will immediately display the current

Preset or Scale Factor value for the selected display. To change any digit, the

user presses the pushbutton directly below that particular digit, which is then

scrolled until the desired value is obtained. Each digit is changed, if necessary,

in the same manner until the complete Preset or Scale Factor value is registered

on the display. Pressing the “E” pushbutton completes the entry sequence.

To interrogate the Preset value, Press “1”:

Unit displays current Preset value.

To change the Preset value:

Any digit may be changed by pressing the pushbutton

directly below it. Release the pushbutton when the digit

reaches the desired value.

Press “E”:

Unit enters new Preset value and returns display to the

present selected display value.

The Gemini 5200 Series can display any of three

selected display values as indicated by LEDs along the left

side of the display.

To display a different value:

Press the “+/-” pushbutton repeatedly until the indicator

corresponding to the desired value turns on.

MONITORING TWO SEPARATE RATES IN ONE

PROCESS

Many applications require more than one rate to be monitored for a

given process. The Gemini 5200 allows the monitoring of two independent

rates with one instrument and provides separate scaling for each channel

when required.

In this example, an industrial saw blade is used to cut timbers to length.

The application requires monitoring both saw blade speed in RPM and feed

rate in tenths of inches per minute. The blade is moved into the material

with a lead screw which makes 12 revolutions per inch of travel. The lead

screw is driven by a 1750 RPM motor through a 2:1 gear reducer which

yields a speed of 875 RPM. Since the blade moves 1 inch in 12 revolutions,

the feed rate of the blade will be 72.9 inches per minute. (875 RPM/12

revolutions per in. = 72.9 in./min.)

A Model LMPC sensor is used to sense a raised target on the lead screw

which delivers 1 pulse per revolution to Rate Channel A of the Gemini 5200.

In terms of travel, one pulse represents 0.0833" (1/12"). However, since the

desired readout is in tenth inches, the input must be multiplied by 10.

Therefore, a scale factor of 0.8333 is programmed into Channel A. A decimal

point is programmed to the left of digit 1 and the Rate A conversion factor is

programmed for Rate per Minute (x60) which automatically multiplies the

input pulses by 60 to yield a direct readout in inches per minute.

Measuring saw blade speed is a simple matter of using an LMPC sensor

to detect a keyway in the blade drive shaft which delivers one pulse per shaft

revolution to Channel B of the Gemini 5200. Programming the Rate B scaler

for rate per minute (x60) yields a direct reading of blade speed in RPM.

GEMINI 5200 APPLICATIONS