Alibrating, Eter – Red Lion PAXLRT User Manual

Page 7

7

To enter Calibration Mode, select

< >

at the end

of Programming Mode, and press the PAR key. In Calibration Mode, the user

can restore the meter to factory default settings or recalibrate the signal input if

necessary.

To prevent inadvertent entries, an access code must be entered to perform any

operation in Calibration Mode. Upon entering Calibration Mode, the meter

initially displays Code 50. Press the up or down arrow keys to select the access

code for the desired operation. If an access code other than those shown below

is entered, the meter exits Calibration Mode and returns to normal display mode.

The factory settings for the programming parameters are shown in the

previous section in the alternating display illustrations. All programming

parameters can be restored to the factory default settings by entering the access

Code 66 and pressing the PAR key. The meter briefly displays

and then

returns to Code 50. This procedure resets only parameters that are accessed

through Programming Mode. The Calibration Mode settings (input calibration

levels) are not affected.

The meter has been fully calibrated at the factory. If the meter appears to be

indicating incorrectly or inaccurately, refer to the troubleshooting section

before attempting this procedure. When re-calibration is required (generally

every 2 years), the procedure should only be performed by qualified

technicians using appropriate equipment. Resistance source accuracies of

0.02% or better are required.

The procedure consists of applying accurate signal levels to the meter input

in a series of two steps. Allow a 30-minute warm-up period before starting

calibration. To begin the input calibration, enter access Code 48 and press the

PAR key.

ENTER ZERO REFERENCE

Meter displays

. Apply 0 ohms to the meter input by shorting Terminals 4,

5, and 6. Allow the meter to stabilize at least 20 seconds after shorting the

terminals, and then press PAR.

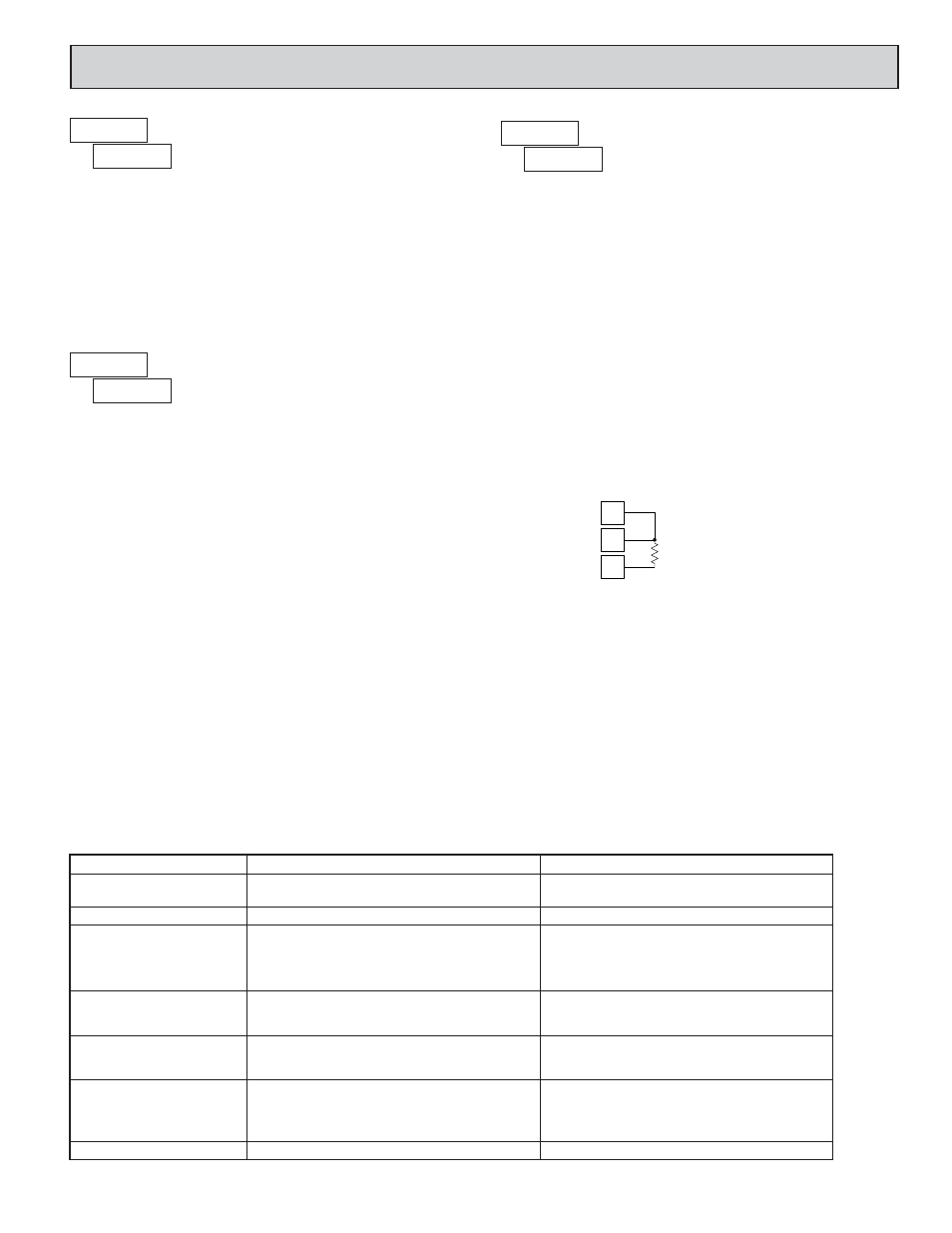

APPLY PRECISION RESISTANCE

Meter displays

. Connect a precision 300 ohm resistor across Terminals

5 and 6. Terminals 4 and 5 remain shorted. (Note: Be certain to short Terminals

4 and 5 at the resistor as shown in the drawing below. Shorting terminals may

lead to incorrect calibration.)

Allow the meter to stabilize at least 20 seconds after making the connections,

and then press PAR. The meter briefly displays

and returns to the normal

display mode. Calibration is now complete. It is recommended to check

calibration by comparing the displayed temperature with a precision thermometer.

to

TROUBLESHOOTING

The majority of all problems with the meter can be traced to improper connections or improper programming set-ups. Be sure all connections are

clean and tight and check the programming set-ups for correct data.

For further technical assistance, contact technical support at the appropriate company numbers listed.

CALIBRATION MODE

FACTORY SETTINGS

METER INPUT CALIBRATION

6

5

4

300

Ω

5.0 C

ALIBRATING

THE

M

ETER

PROBLEM

POSSIBLE CAUSE

REMEDIES

NO DISPLAY

1. Power off, improperly connected, or brown-out.

“

” IN DISPLAY

1. Program data error.

1. Press PAR and check data set-ups.

“

” or “

” IN DISPLAY

1. Input display out of range.

2. Loss of data set-ups.

DISPLAY WANDERS

1. Loss of data set-ups.

1. Electrical “Noise” in process or sensor lines.

2. Process inherently unstable.

“

” IN DISPLAY

1. Connect probe.

2. Repair or obtain new probe.

3. Reduce temperature.

4. Check input levels.

“

” IN DISPLAY

1. Input shorted.

1. Check input connections.

1a. Check data set-ups.

1b. Disconnect and reconnect power.

1c. Check for electrical disturbance.

1a. Check wiring.

1b. Verify power.

1a. Change display resolution to “1” degree.

1b. Reduce offset value.

2a. Check data set-ups.

2b. Check for electrical disturbance.

2c. Disconnect and reconnect power.

1a. Increase digital filtering.

1b. Re-route signal wires.

2. Dampen process to eliminate oscillations.

1. Probe unconnencted.

2. Broken or burnout probe.

3. Excessive probe temperature.

4. Input overload.

JITTERY DISPLAY