Roubleshooting, Alibration, Paxli – Red Lion PAXLVD User Manual

Page 7: Direct current meter readout, Scaling current meter readout, Block diagram paxli, Input calibration

7

DIRECT CURRENT METER READOUT

When the application requires direct current meter readout, the Scale Switch

should remain in the “OFF” position. The Input Range Jumper is set to the

current range being applied. It is possible to select a range higher than being

applied to get lower resolution. The Decimal Point switches are set to resolution

of the selected Input Range Jumper.

SCALING CURRENT METER READOUT

In many industrial applications, a current meter is required to display a

reading in terms of PSI, RPM, or some other unit of measure. The signal voltage

being measured can be generated by a transducer that senses the variations and

delivers a linear output voltage. To provide the desired readout at the specified

current, the current meter must be scaled.

Place the Scale Switch in the “ON” position. This enables the Scale

Potentiometer which is accessible from the back of the meter. (Enabling the

Scale Potentiometer does NOT affect the calibration of the meter.) Place the

Decimal Point Switches to the proper location. The Input Range Jumper is set

to the current range being applied. Apply the meter power and the current signal.

Adjust the Scale Potentiometer to the desired value. Scaling to obtain a

numerical readout higher than the normal value of the current can also be

accomplished, in most cases, by selecting a lower current range. However, the

maximum current for the range must not be exceeded. (See Specifications for

maximum input currents.)

This scaling only effects the span. There is no offset scaling. This means that

only zero amps can display a value of zero.

EXAMPLE: The Pax Current Meter has been connected to measure a circuit

current to 120.0 mA maximum. However, in this application, the display is to

indicate percent of load current with 120.0 mA equivalent to 100.0 percent.

The scale potentiometer is adjusted to reduce the normal 120.0 mA signal

input display reading of 120.0 to indicate the desired reading of 100.0 on the

display. Scaling to obtain a numerical readout higher than the normal value

of the current can also be accomplished in most cases by selecting a lower

current range. However, the maximum current for the range must not be

exceeded. (See Specifications for maximum input currents.)

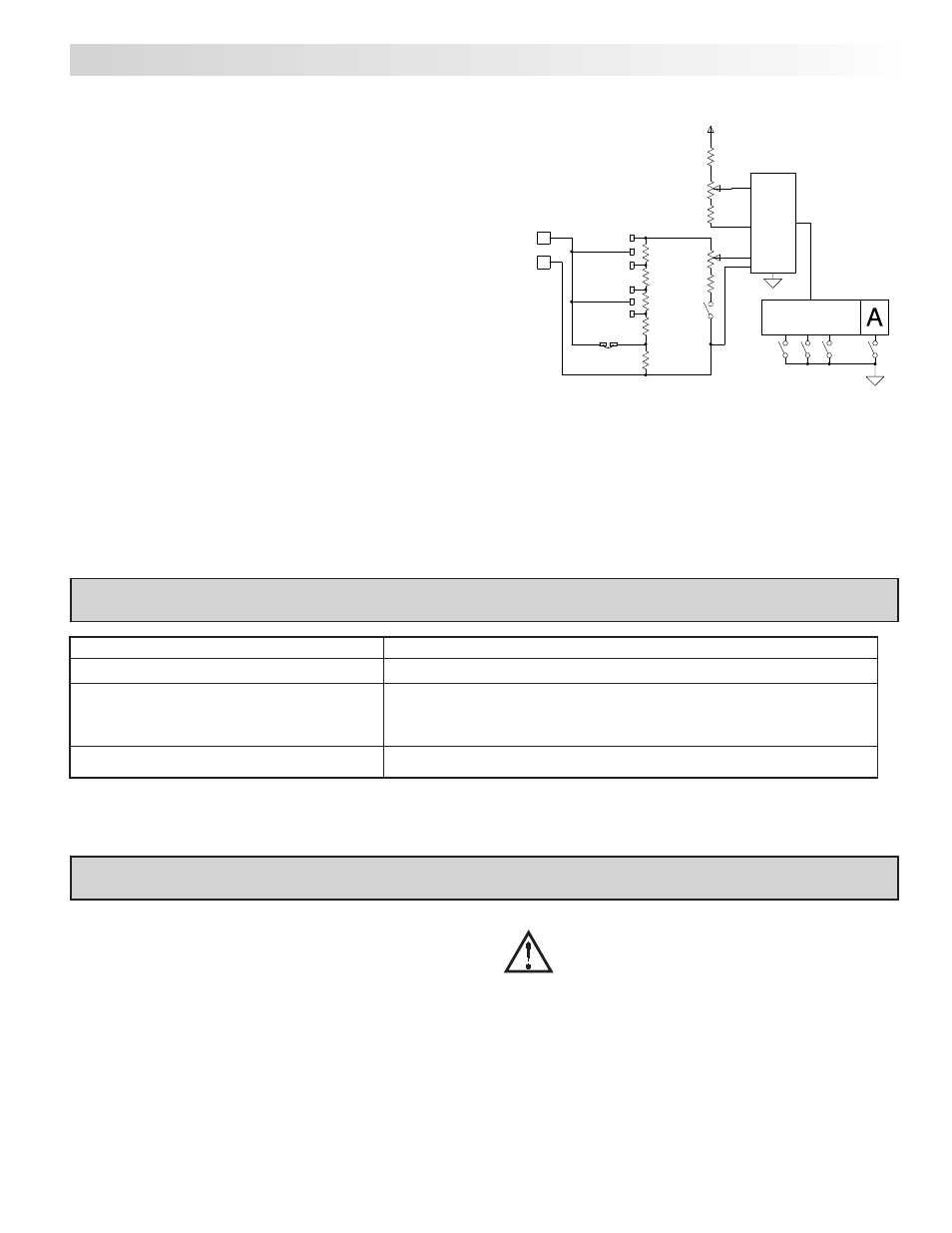

PROCESS

CIRCUITRY

+VDC

S3

S2

S1

S4

COMMON

+SIGNAL

0-199.9mA

0-19.99mA

1

Ω

9

Ω

S5

0-1.999mA

0-199.9

µA/

90

Ω

900

Ω

POT

SCALE

.1

Ω

0-1.999A

1.9.9.9

199.9mV

BLOCK DIAGRAM PAXLI

PROBLEM

REMEDIES

NO DISPLAY

CHECK

: Power switch and line voltage

INCORRECT DISPLAY

OVER-RANGE INDICATION

CHECK

: Input jumper position

VERIFY

: Input signal

CHECK

: Input jumper position

CHECK

: Scaling adjustment pot DIP switch position

ADJUST

: Scaling pot

VERIFY

: Input Signal

For further assistance, contact technical support at the appropriate company numbers listed.

PAXLI

5.0 T

ROUBLESHOOTING

6.0 C

ALIBRATION

The meter has been fully calibrated at the factory. Scaling to convert the input

signal to a desired display value is performed by enabling the scale pot DIP

switch. If the meter appears to be indicating incorrectly or inaccurately, refer to

Troubleshooting before attempting to calibrate the meter.

When recalibration is required (generally every 2 years), it should only be

performed by qualified technicians using appropriate equipment.

Input Calibration

WARNING: Calibration of this meter requires a signal source

with an accuracy of 0.01% or better and an external meter with an

accuracy of 0.005% or better.

Before starting, verify that the Input Range Jumper is set for the range to be

calibrated. Also verify that the precision signal source is connected and ready.

Allow a 30 minute warm-up period before calibrating the meter.

Then perform the following procedure:

1. Place jumper in 2 V range (PAXLV) or 2 mA range (PAXLI).

2. Set the DIP switch off to disable the scaling pot.

3. Apply half scale input signal.

4. Adjust calibration potentiometer as necessary for the display to read 1000

(ignore decimal point).

5. Apply zero signal and ensure display reads zero.

6. Apply full scale signal and ensure display reads 1999.

Note: Any individual range may be recalibrated (scaled) to 0.1% accuracy with

appropriate calibration equipment.