Maintenance – JKS OGS155 User Manual

Page 3

JKSOGS155

JKS Adjustable Trackbar Installation

Page 3

IMPORTANT: If Bushing Sleeve at Axle End is not

parallel with axle bracket mounting holes, first confirm

that factory bend in Axle End of trackbar is pointing

towards the front of vehicle. If Bushing Sleeve is still

out of alignment, it may be necessary to slightly bend

Axle End of trackbar using a hydraulic press. Varia-

tions in the axle bracket position are typically the

result of modifications to related suspension parts

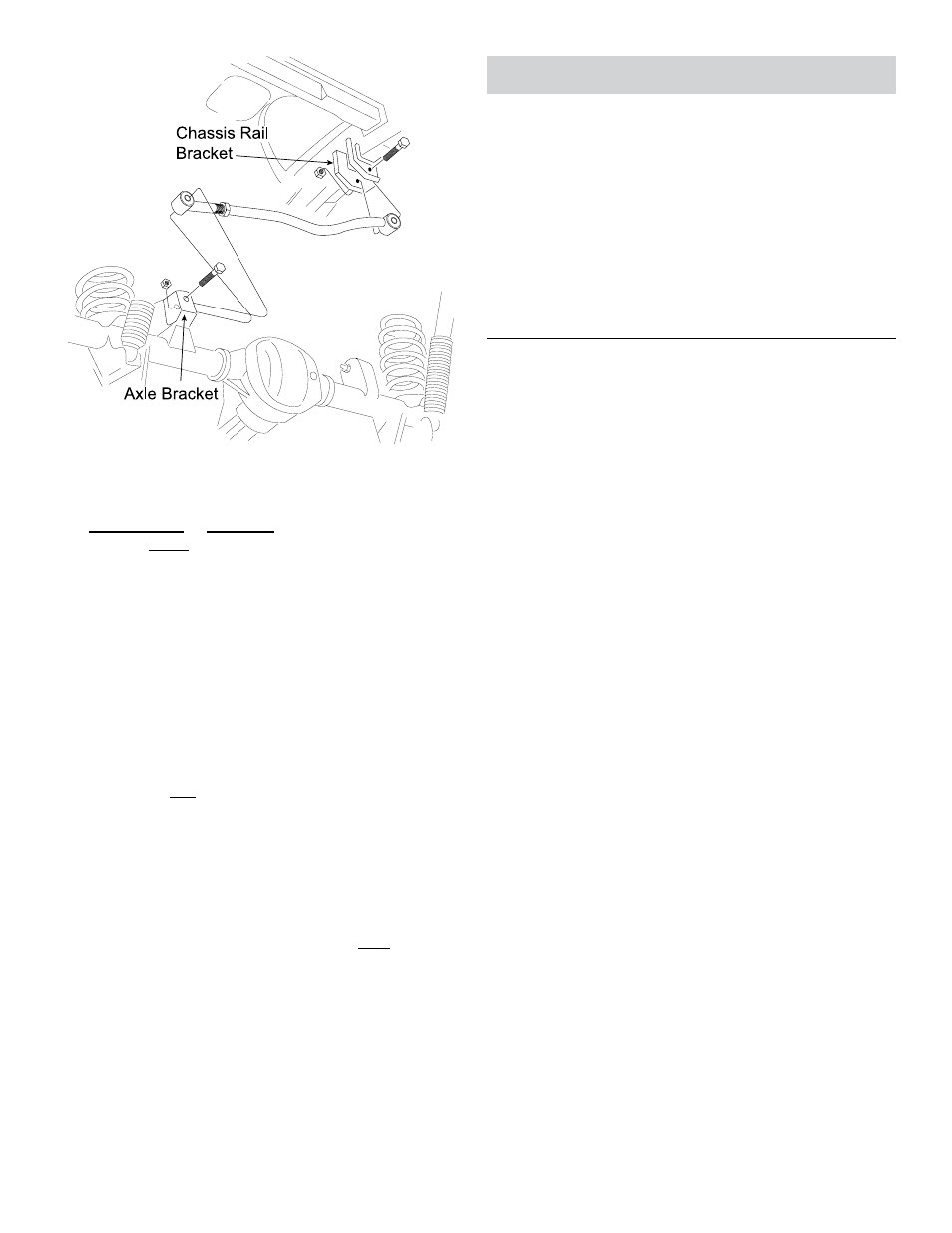

HINT: The factory rear trackbar bracket on axle utilizes a

“pocket” design that requires the Adjustable Trackbar be

removed from the chassis bracket before Axle End (A) can

be inserted. This may not be necessary if an aftermarket

extension bracket has been installed on the factory axle

bracket.

Apply anti-seize lubricant to original mounting bolt

threads and adjustment threads of trackbar.

Install Axle End (A) of Adjustable Trackbar to the

axle bracket by securing with the original mounting

hardware.

Take measurements again to ensure axle housing

is perfectly centered and make any final adjust-

ments if necessary.

Once all adjustments are complete, fully tighten

the Jam Nut (C) to prevent Adjustable Trackbar

length from changing.

HINT: It may be easier

to tighten Jam Nut with the Adjustable Trackbar

removed from the vehicle.

Tighten mounting bolts on axle bracket and chas-

sis rail bracket to 50 ft-lb. using a torque wrench.

Maintenance

Check torque specifications regularly.

Regular cleaning with pressurized water is recommended

to maximize reliability.

The original equipment trackbar uses the same bushing

size as the JKS Adjustable Trackbar. Upon removal of the

original trackbar, the OE bushings should be retained if in

good condition. In the unlikely event that the Adjustable

Trackbar bushings wear out, the OE trackbar bushings

may be used as replacements.

©2013 JKS Manufacturing, Inc & Aftermarketing, LLC

Revision Date 10/31/2013