Installation – JKS BSE201 User Manual

Page 2

JKSBSE201

JKS Hydraulic Bump Shocks Installation

2 Page

Installation

1. REMOVE FRONT COIL SPRINGS

Remove the front coil springs per the factory ser-

vice manual instructions for your vehicle.

HINT: A coil spring compressor is useful for removal.

Depending on the application, it may be necessary

to completely or partially remove any of the

following components before spring can be free

from upper mount.

Â

Shock Absorber

Â

Swaybar

Â

Brake Line

Â

ABS Wire

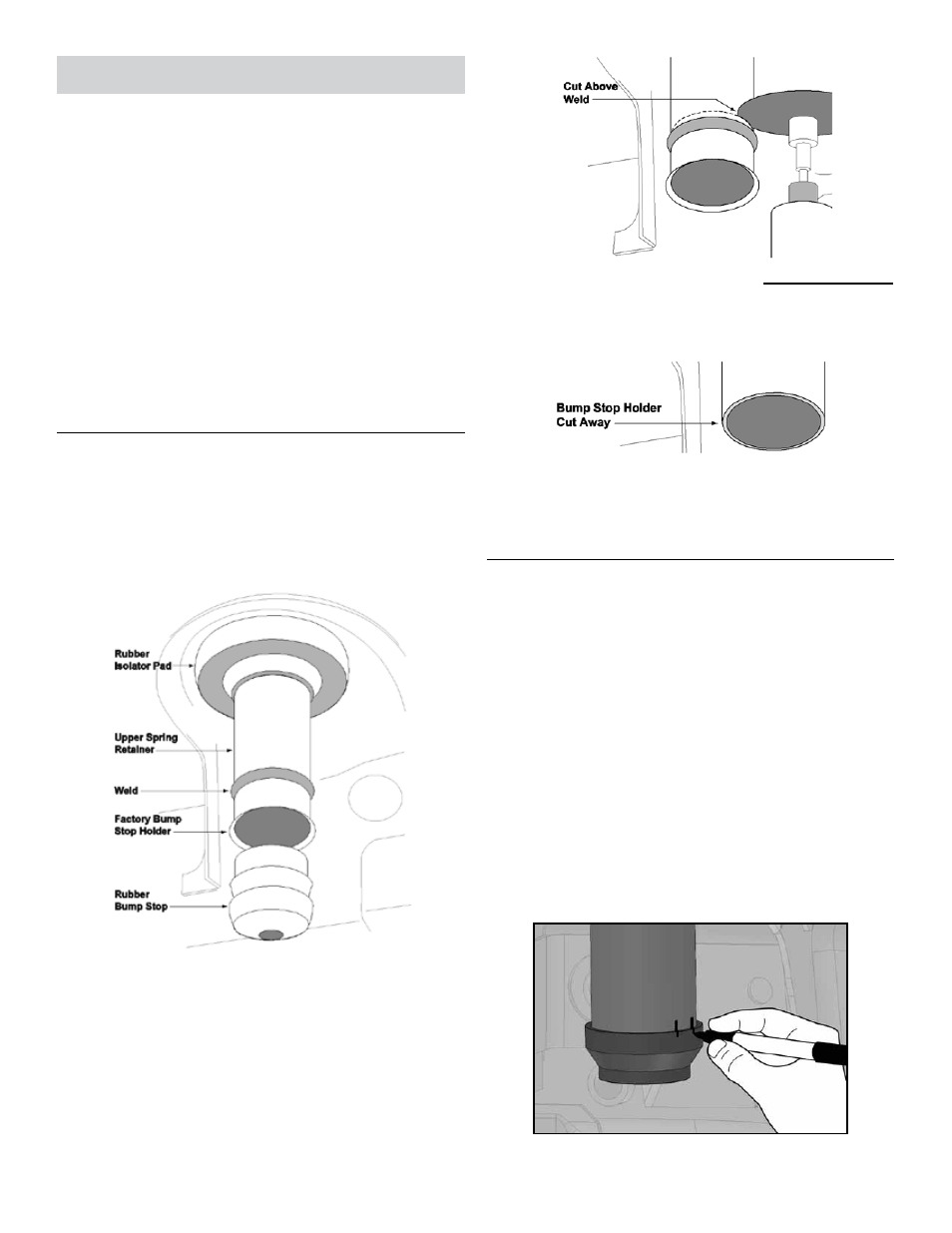

2. MODIFY SPRING RETAINER

The factory bump stop holder is welded to the upper spring

retainer and must be permanently removed in order to

install the Hydraulic BumpShocks.

Pry the original rubber bump stop (jounce bumper)

free from the bump stop holder.

Locate the factory weld that secures the bump

stop holder to the upper coil spring retainer.

Cut away the bump stop holder immediately above

the weld as illustrated.

HINT: A die grinder with

cut-off wheel or reciprocating saw is useful for cut-

ting away the bump stop holder.

Remove any sharp edges from the cut portion of

the upper spring retainer.

HINT: A file or deburring

tool is useful for removing sharp edges.

3. PREPARE FOR WELDING

Locate the supplied Jounce Adapters (C). The

adapters are zinc plated from the factory to pre-

vent corrosion. In preparation for welding, a small

amount of plating must be removed to ensure the

areas to be welded are clean.

Slide the enlarged (non-threaded) end of the

Jounce Adapter (C) onto the upper spring retainer

until fully seated. Hold in position while completing

the next step.

Mark the perimeters of the upper spring retainer

AND the Jounce Adapter (C) where they meet at

three (3) locations that are accessible for weld-

ing. Each weld location should be at least 1/2” in

length and spaced evenly apart.

HINT: A felt tip

marker or similar marking tool is useful for marking

weld locations.

HINT: A pair of vertical lines spaced 0.5” apart is

used to mark each weld location.