JKS 6125 User Manual

Page 2

JKS6125

JKS Adjustable Control Arm Installation

2 Page

Remove the lower suspension arm nut and bolt

from the axle housing bracket. Retain the original

mounting hardware.

Remove the nut and bolt from the chassis rail

bracket. Retain the original mounting hardware.

Remove the original lower suspension arm from

the vehicle.

2. SET CONTROL ARM LENGTH

Adjustable Control Arms are fully collapsed when supplied

from JKS and must be adjusted to the desired lengths

before installation.

The working length of each lower Control Arm can be in-

creased (up to 2.25” longer), decreased (up to 1.0” short-

er), or exactly the same as the OE suspension arm.

Determine ideal Control Arm length for your ap-

plication by considering factors such as:

Â

Length of OE suspension arm

Â

Tire Clearance

Â

Pinion Angle

Rotate adjustable end of Control Arm until the

desired length is achieved.

Adjust corresponding Control Arm to exact same

length.

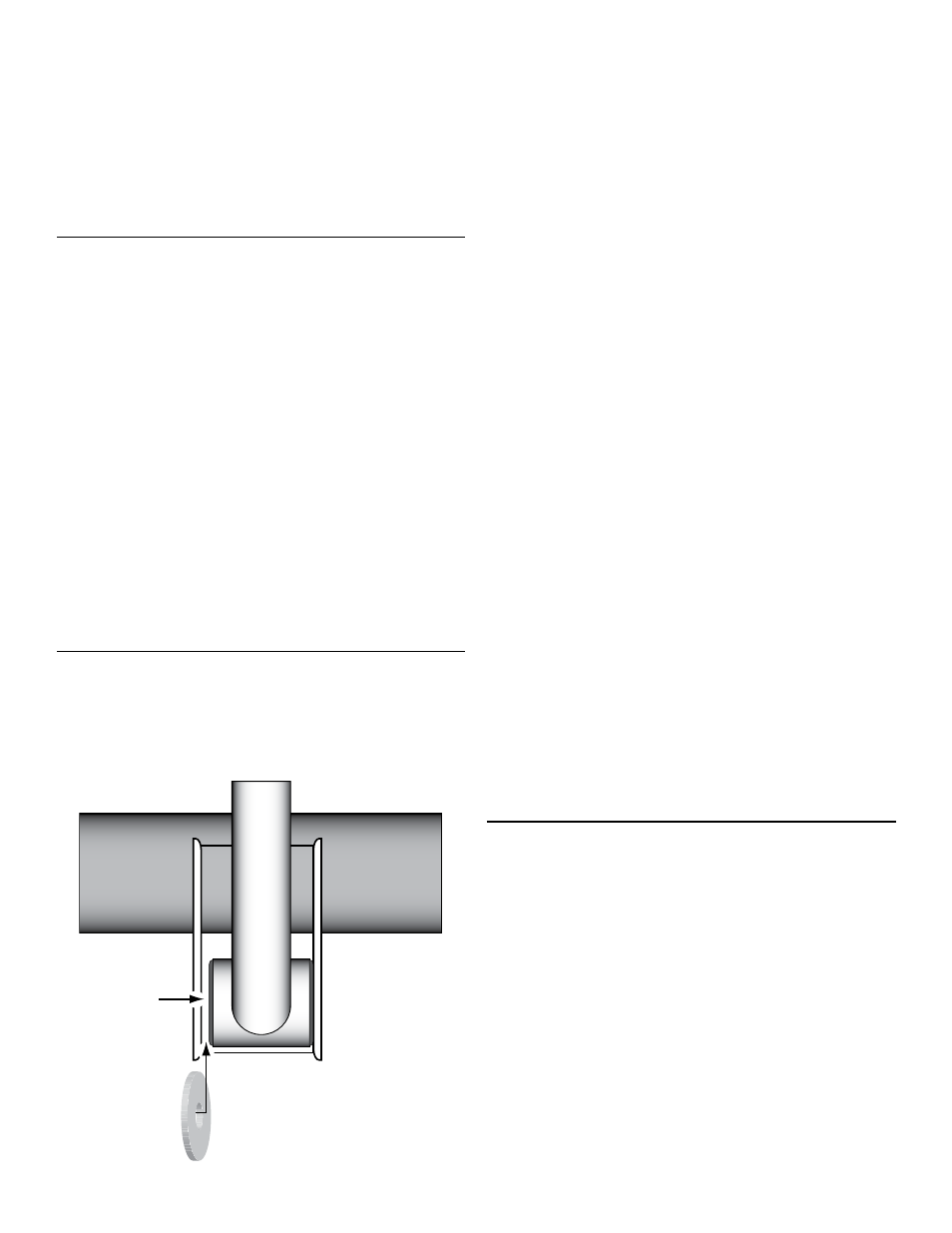

3. INSTALL ADJUSTABLE CONTROL ARM

The factory suspension arm brackets on the chassis and

axle are wider than the Adjustable Control Arm bushings.

Therefore, it will be necessary to insert flat washer shims

between the bracket and bushing to fill this void.

Use flat washer shims

to fill void between

bracket and bushing

VOID

9/16” SAE

FLAT

WASHER

IMPORTANT: Each Control Arm requires three (3) flat

washer shims for installation. Two (2) flat washers are

required for the chassis end of the Control Arm, and

one (1) flat washer is required for the axle end.

For your convenience, enough flat washer shims have

been supplied to accommodate installation of front and

rear lower Control Arms.

Apply anti-seize lubricant to bolt threads of original

mounting hardware.

Mount the non-rotating (BLACK) end of Adjustable

Control Arm to the chassis rail bracket with the

greaseable fitting facing up.

Insert two (2) flat washer shims – one on each

side of bushing – to fill the void between the chas-

sis bracket and Control Arm bushing.

HINT: Flat

washers must be installed to ensure proper bush-

ing performance and reliability.

Install the original mounting bolt and finger tighten

the nut.

DO NOT torque mounting hardware until

instructed.

Mount the rotating (GOLD) end of Adjustable Con-

trol Arm to the axle housing bracket.

Insert one (1) flat washer shim to fill the void

between the axle bracket and Control Arm bush-

ing. HINT: Flat washer must be installed to ensure

proper bushing performance and reliability.

Install the original mounting bolt and finger tighten

the nut.

DO NOT torque mounting hardware until

instructed.

HINT: If mounting bolt is difficult to install due to misalign-

ment of Control Arm bushing with mounting bracket, either

(1) adjust height of axle housing with hydraulic jack, (2)

move axle housing into position with a heavy-duty ratchet

strap, or (3) temporarily disconnect track bar until mounting

holes align.

4. TIGHTEN MOUNTING HARDWARE

Once both Adjustable Control Arms have been

properly installed, lower the vehicle to the ground

until coil springs are supporting the full weight of

vehicle.

Using a torque wrench, tighten the mounting hard-

ware to 130 ft-lbs.