Maintenance – JKS OGS169 User Manual

Page 2

JKSOGS169

JKS Rear Trackbrace Installation

2 Page

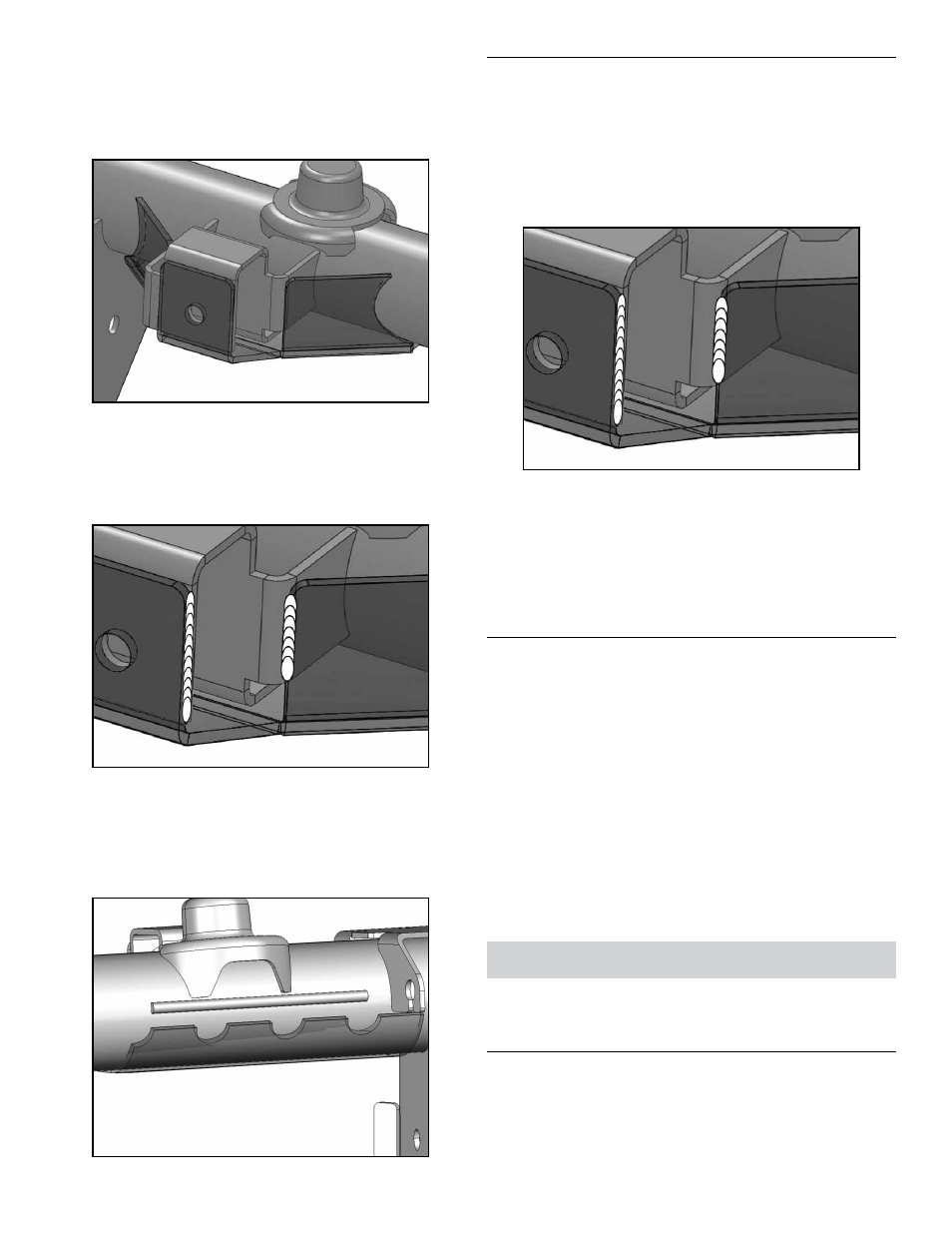

Slide Trackbar Brace over factory track bar brack-

et as illustrated below. Make sure hole in Trackbar

Brace aligns with bolt hole in factory track bar

bracket.

HINT: The snug fit should hold the brace

in position for welding.

IMPORTANT: The Trackbar Brace must be welded to

bare metal. Remove any paint, rust or other contami-

nants before welding.

Thoroughly clean locations marked by an “X” on

both sides of factory track bar bracket.

The indicated locations on back side of axle must

also be prepared for welding.HINT: A die grinder

with sanding wheel or similar tool is useful for

removing paint from axle housing. This step may

be easier with the Trackbar Brace temporarily

removed.

3. WELD TRACKBAR BRACE TO AXLE

HOUSING

With Trackbar Brace correctly positioned over fac-

tory track bar bracket, tack weld the brace to the

axle housing.

Next, fillet weld Trackbar Brace to axle housing in

locations indicated in the previous section.

IMPORTANT: Avoid overheating axle tube by allowing

the surface to cool off regularly.

Once all welding is complete, spray paint entire

Trackbar Brace and any bare metal on axle hous-

ing to prevent corrosion. All exposed metal must

be completely covered.

4. REINSTALL REAR TRACK BAR

Apply anti-seize lubricant to bolt threads of original

track bar mounting hardware.

Insert axle end of track bar into reinforced axle

bracket first. Loosely install original mounting

hardware.

Mount chassis end of track bar and loosely install

original mounting hardware.

IMPORTANT: Vehicle must be on level ground with

coil springs supporting the full vehicle weight before

mounting hardware is tightened.

Using a torque wrench, tighten mounting hardware

at both ends of track bar to 125 ft-lbs.

Maintenance

Check torque specifications regularly.

©2013 JKS Manufacturing, Inc & Aftermarketing, LLC

Revision Date 11/1/2013