JKS OGS115 User Manual

Page 2

JKSOGS115

JKS Mini Skid Installation

2 Page

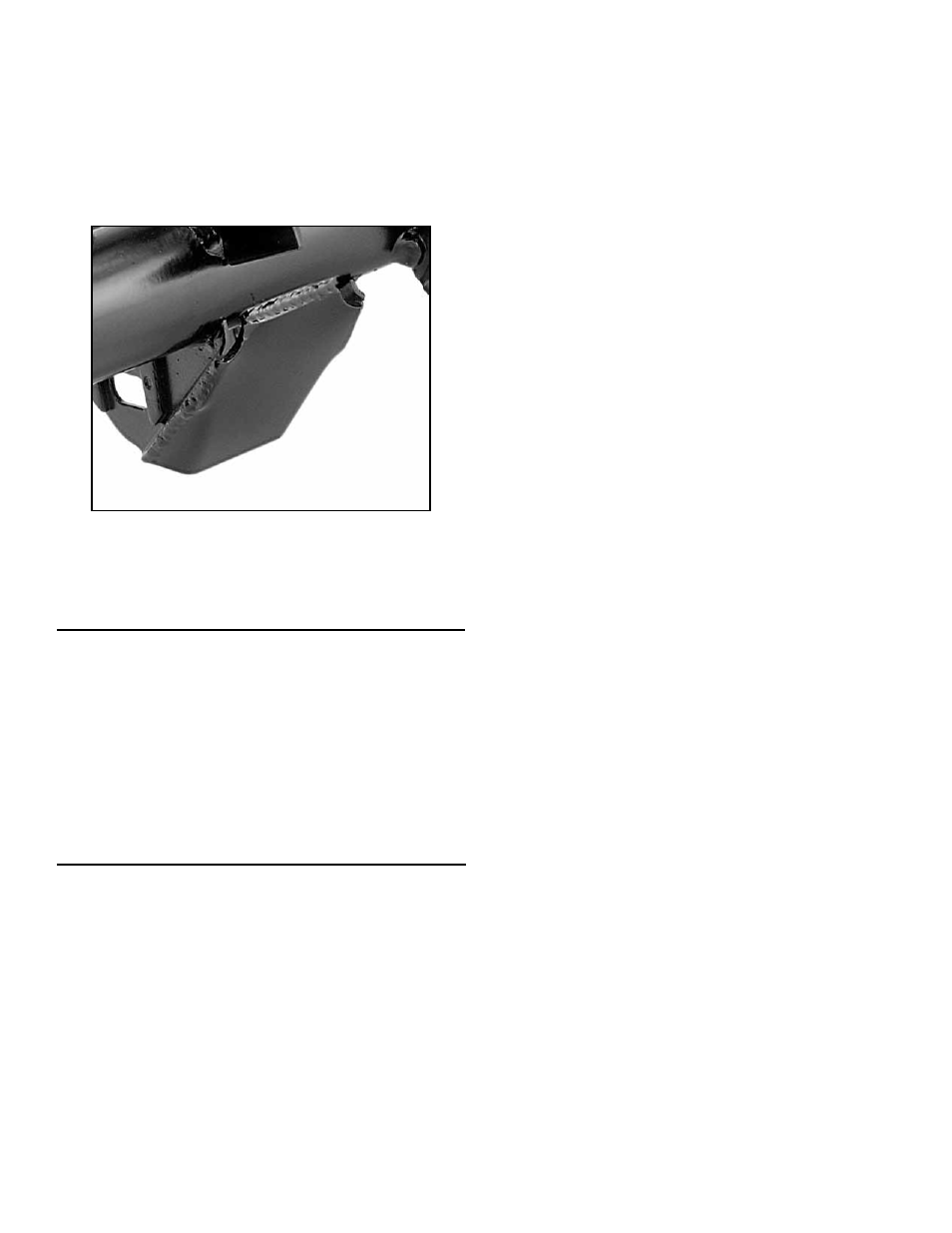

Once positioned correctly, fillet weld “wings” of

MiniSkid to suspension arm bracket.

Hammer “tab” of MiniSkid towards axle tube until

gap measures 1/8” or less.

Fillet weld “tab” of MiniSkid to axle tube.

IMPORTANT: Avoid overheating the axle tube by

allowing the surface to cool off regularly.

Once all welding is complete, spray paint any bare

metal on MiniSkids, suspension arm brackets, and

axle tube to prevent corrosion. All exposed metal

must be completely covered.

3. REINSTALL SUSPENSION ARMS

Reinstall lower front suspension arm to axle

bracket using the original mounting hardware.

HINT: It will be necessary to unbolt chassis end

of suspension arm in order to insert axle end into

“pocket” formed by MiniSkid.

Using a torque wrench, tighten the suspension

arm mounting hardware to the factory torque

specifications for your vehicle.

©2013 JKS Manufacturing, Inc & Aftermarketing, LLC

Revision Date 10/31/2013