Dwyer DPW User Manual

Page 4

To eliminate the possibility of noise interference, use a separate cable entry for the

DC power and analog signal lines (pins L, M, K on “M16” connector).

2.2.3 Flow Sensor Pulse Output Signals Connections

Pin C -------- (+) Flow Sensor Pulse Output (active), 3.3Vdc

Pin B ------------ DC Power (-), Digital Common

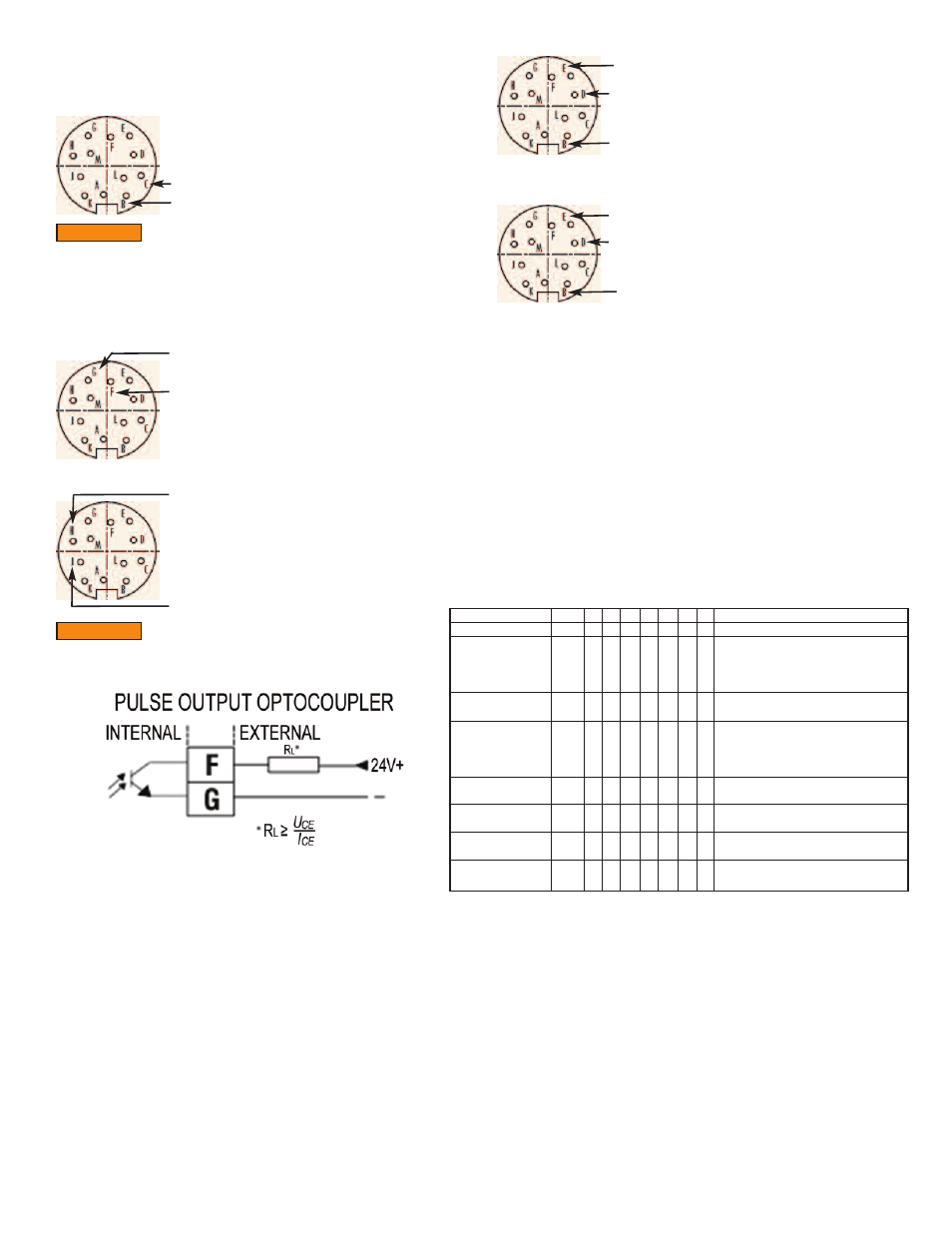

2.2.4 Programmable Optically Isolated Output Signals Connections

Optocoupler #1 (pins F and G):

Pin G ------------ Plus (-) (passive)

Pin F ------------ Plus (+) (passive)

Optocoupler #2 (pins H and J):

Pin H ------------ Plus (+) (passive)

Pin J ------------ Plus (-) (passive)

2.2.5 Communication Parameters and Connections

The digital interface operates via RS485 (optional RS-232) and provides access to

applicable internal data including: flow, temperature, totalizers and alarm settings,

flow linearizer table, fluid density and engineering units selection.

Communication Settings for RS-485/RS-232 communication interface:

Baud rate:

------------

9600 baud

Stop bit:

------------

1

Data bits:

------------

8

Parity:

------------

None

Flow Control:

------------

None

RS-485 communication interface connection:

The RS485 converter/adapter must be configured for: multidrop, 2 wire, half duplex

mode. The transmitter circuit must be enabled by TD or RTS (depending on which

is available on the converter/adapter). Settings for the receiver circuit should follow

the selection made for the transmitter circuit in order to eliminate echo

.

Pin E ------------ RS-485 T(+) or R(+)

Pin D ------------ RS-485 T(-) or R(-)

Pin B ------------ RS-485 GND (if available)

RS-232 communication interface connection:

Crossover connection has to be established:

Pin E ------------ RS-232 TX

(pin 3 on the DB9 connector)

Pin D ------------ RS-232 RX

(pin 2 on the DB9 connector)

Pin B ------------ RS-232 SIGNAL GND

(pin 5 on the DB9 connector)

2.3 - SPECIFICATIONS

Service: Liquids compatible with wetted materials.

Wetted Materials:

DPW-XP: Polypropylene and fluoroelastomer O-rings, PVDF and nickel

tungsten carbide paddlewheel, acrylic lid.

DPW-XT: PVDF and fluoroelastomer O-rings, PVDF and zirconia ceramic

paddlewheel, PVDF lid; Bearings: PVDF sapphire.

Accuracy: ±1% FS.

Repeatability: ±0.25% FS.

Response Time: 1 second above 10% of FS, 2 seconds below 10% of FS.

Output Signal: Linear 0 to 5 VDC (3000 Ω min. load impedance); 4 to 20 mA (500

Ω max. loop resistance).

Pulse Output: 3.3 VDC, 3K min. load impedance.

Digital Interface: RS-232; RS-485.

Temperature Limits: 14 to 140°F (-10 to 60°C).

Pressure Limit: 10 bar (150 psig).

Power Requirements: 11 to 26 VDC.

Display: 2 row, 16 character LCD with backlight (optional).

Process Connections: Female NPT.

Weight: 1.60 lb (0.73 kg).

The flow sensor pulse output is self-powered (open drain,

pulled up with 10K resistor to internal 3.3Vdc rail). Do NOT

connect an external voltage source to the pulse output signals. Use load with

input impedance more than 30K is recommended.

WARNING

Optically isolated outputs require application of DC voltage

across terminals. Do not exceed maximum allowed limits for

voltage and current provided below:

WARNING

Example

Series

Orifice Size

(Flow Range)

Material Lower

Block

Seals

Display/Keypad

RTD Option

Output Signal

Digital Interface

DPW

DPW

05

05

10

17

35

P

P

T

E

E

T

B

V

L

N

L

N

N

R

A

A

B

2

2

5

DPW-05-ELN-A2

Flow Transmitter

0.04 to 5 gal/min (0.15 to 18.9 L/min)

0.08 to 10 gal/min (0.3 to 37.6 L/min)

0.15 to 17 gal/min (0.6 to 64.4 L/min)

0.35 to 35 gal/min (1.3 to 132.5 L/min)

Polypropylene

PVDF

EPDM

PTFE

Buna-N

Fluorelastomer

No Display/No Keypad

LCD/Keypad

No RTD

RTD

0 to 5 VDC

4 to 20 mA

RS-232

RS-485

Page 4